Method for generating energy from hydrogen production bacteria and oily microalgae in stair-coupling mode

A technology of bacteria and microalgae, applied in the field of bioenergy, can solve the problems of difficult utilization of fermentation products, low substrate utilization rate, and low production efficiency, and achieve the goal of accelerating the pace of industrialization, high substrate utilization rate, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

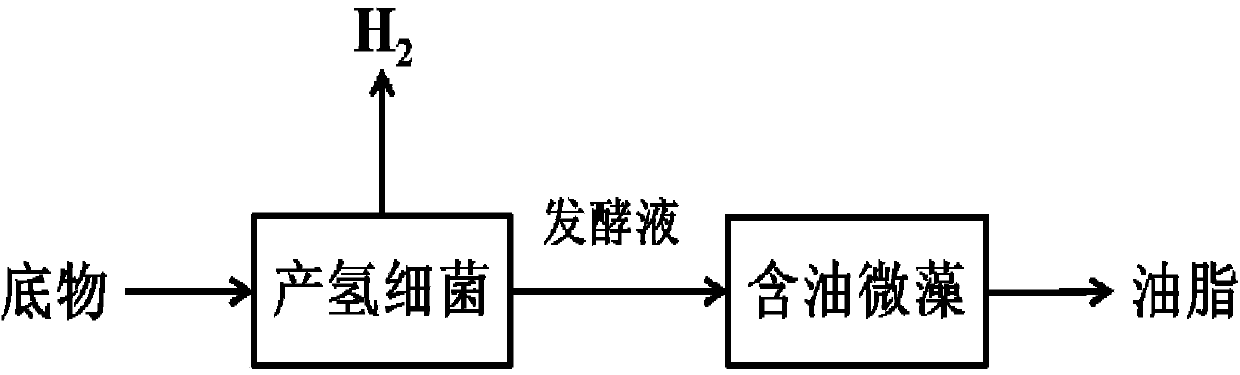

[0021] Specific implementation mode 1: In this implementation mode, a method for coupling production capacity of hydrogen-producing bacteria and oil-containing microalgae is carried out according to the following steps:

[0022] 1. Take hydrogen-producing bacteria for cultivation;

[0023] 2. Centrifuge the organic acid fermentation liquid produced by the hydrogen-producing bacteria in step 1, take the supernatant to adjust the pH to 6-9, and then perform high-pressure steam sterilization;

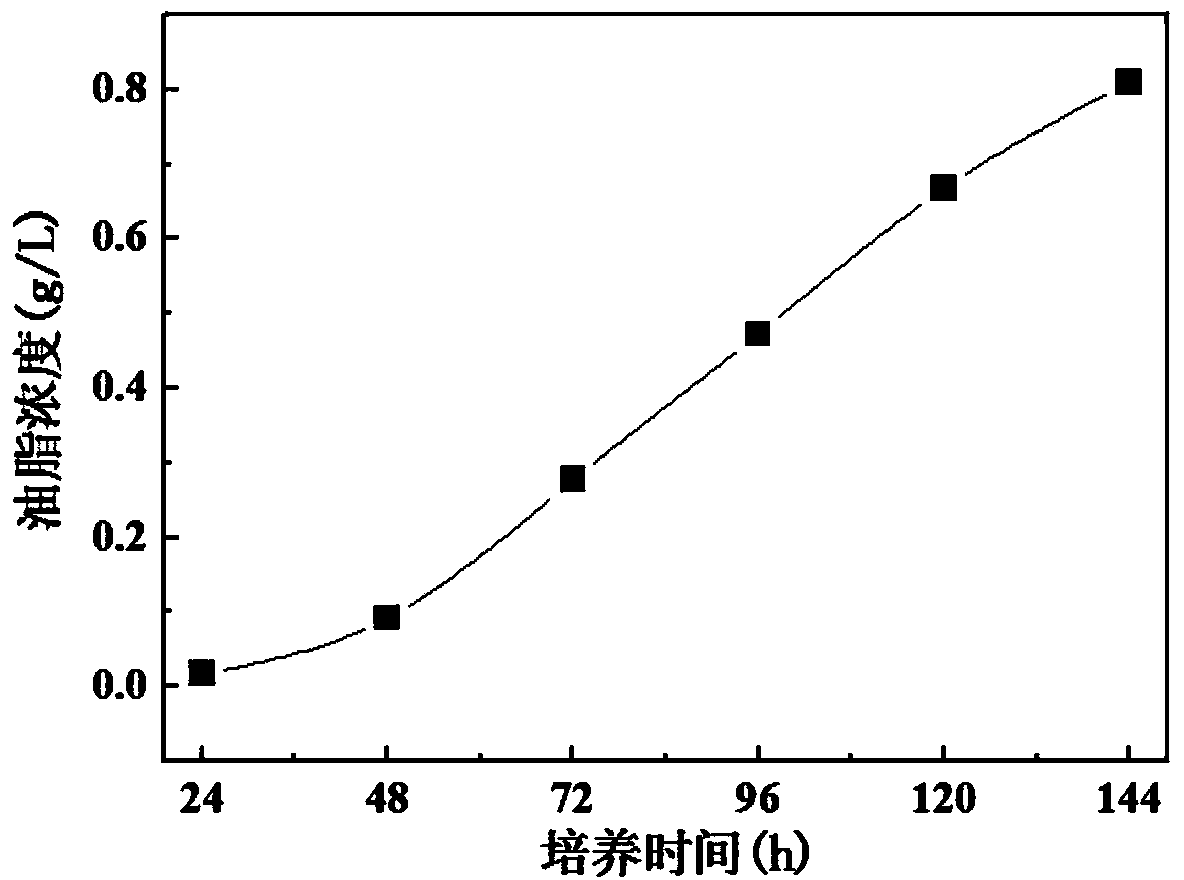

[0024] 3. Inoculate oil-containing microalgae into the sterilized supernatant of step 2 for cultivation;

[0025] 4. Harvesting the oleaginous microalgae cultivated in step 3, and then extracting the oil in the oleaginous microalgae.

[0026] The beneficial effect of this implementation mode:

[0027] 1. The combination of dark fermentation hydrogen production technology and microalgae oil production technology can simultaneously solve the two bottleneck problems of raw material shortage...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the hydrogen-producing bacteria described in step 1 are Ethanoligenens harbinense, Clostridium pasteurianum, Escherichia coli ), Clostridium butyricum, Clostridium acetobutylicum, and Enterobacter aerogenes were mixed in any ratio. Others are the same as in the first embodiment.

[0032] The hydrogen-producing bacteria described in this embodiment are all purchased.

specific Embodiment approach 3

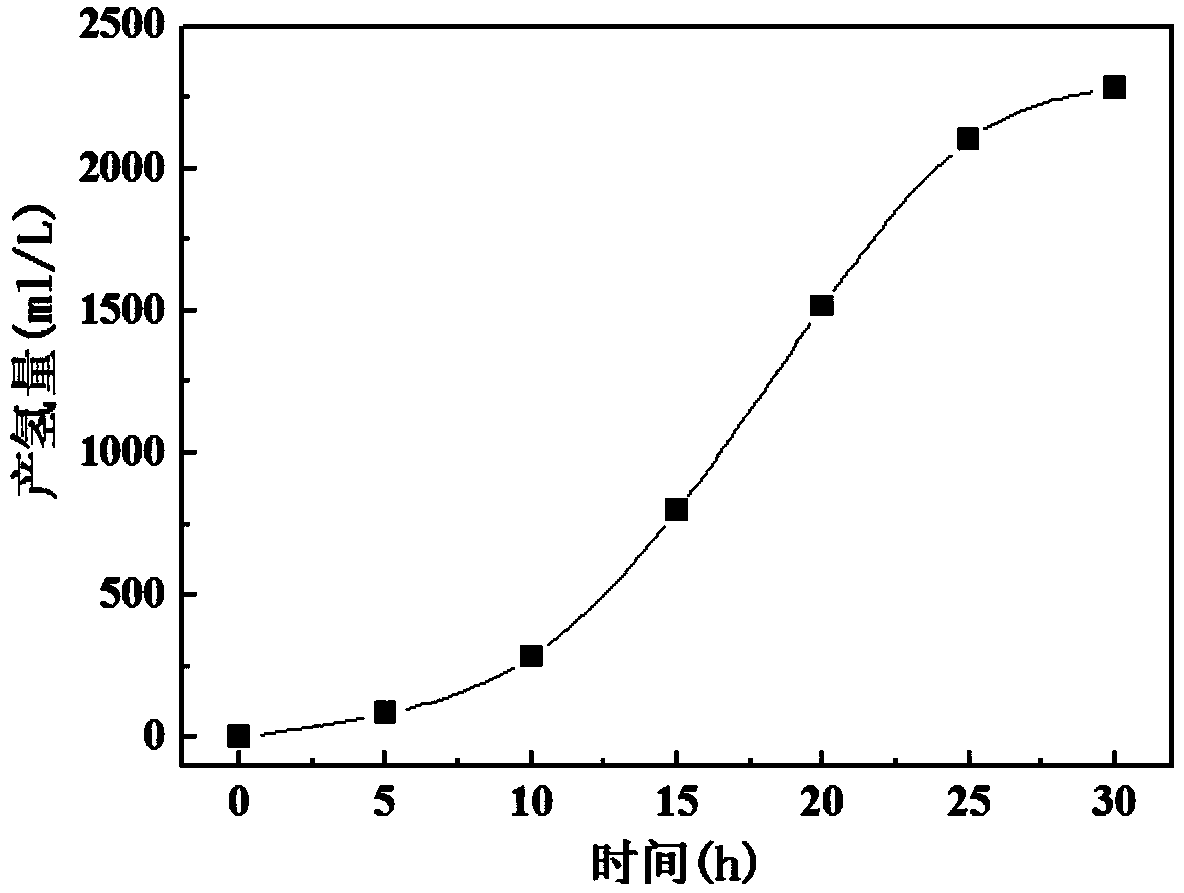

[0033] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that the hydrogen-producing bacteria culture conditions described in step 1 are at a temperature of 35°C to 37°C, protected from light, filled with nitrogen to isolate the air culture, and the culture time 20 to 40 hours. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com