Flaky vanadium dioxide film material and preparation method thereof

A technology of vanadium dioxide flake and thin film materials, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of unstable product performance, harsh reaction conditions, and difficulty in large-scale industrial production, and achieve The effect of good controllability of film morphology and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take an appropriate amount of vanadyl sulfate and dissolve it in a mixture of deionized water and ethanol at a volume ratio of 1:1, with a concentration of 0.2mol / L;

[0027] (2) Add sodium chloride and dispersant, stir for 20 minutes, and ultrasonically disperse for 30 minutes to obtain a blue clear solution;

[0028] (3) Adjust the pH value of the solution to 2.6-2.7, and let it stand for 3 days;

[0029] (4) Wash and dry the FTO substrate in sequence with ethanol, acetone, hydrochloric acid, and deionized water;

[0030] (5) Put the substrate and electrodes into the electrolyte in parallel with a distance of 2.5cm, apply a DC voltage of 1.5V, and power on for 20 minutes to perform anodic oxidation deposition coating;

[0031] (6) After the deposition, the sample was dried at 100°C for 40 minutes, and then annealed at 510°C for 12 hours in a nitrogen atmosphere to obtain a thin film.

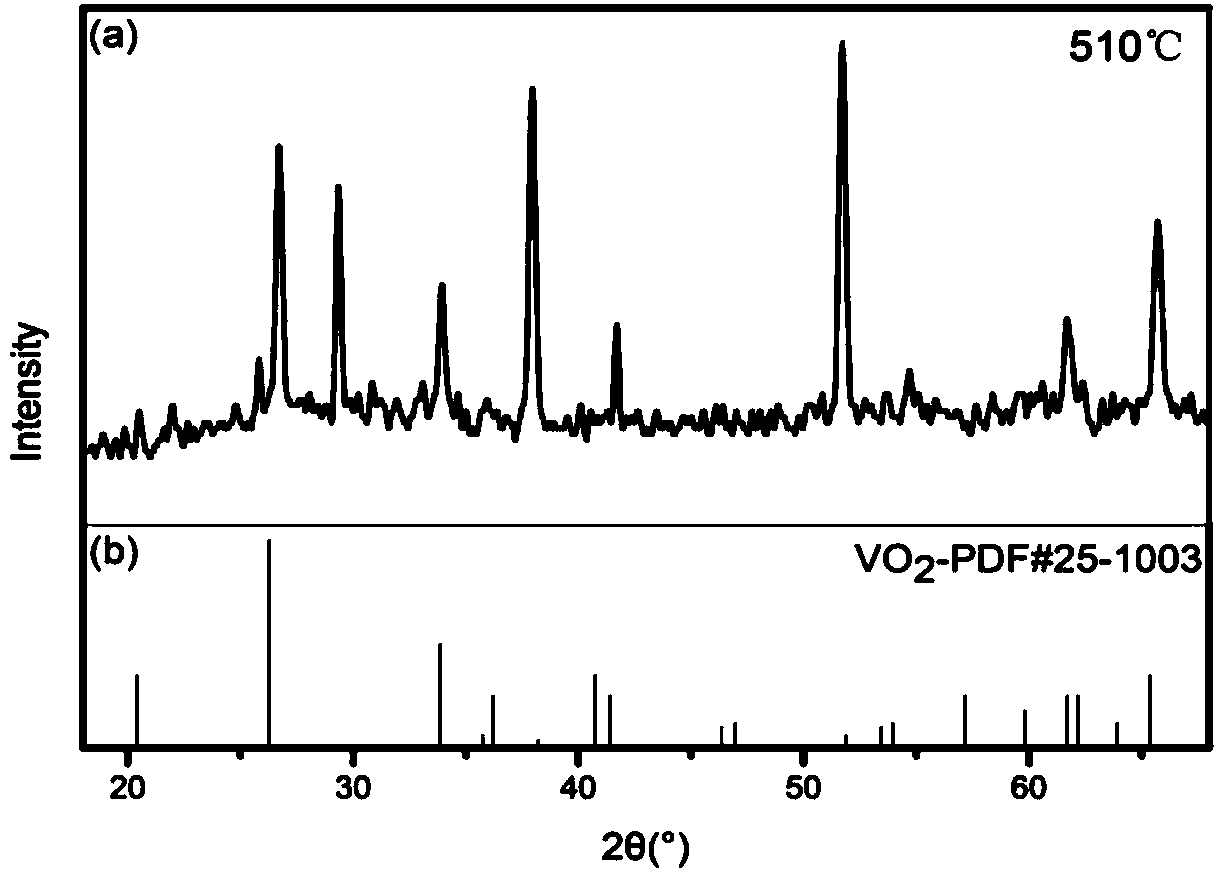

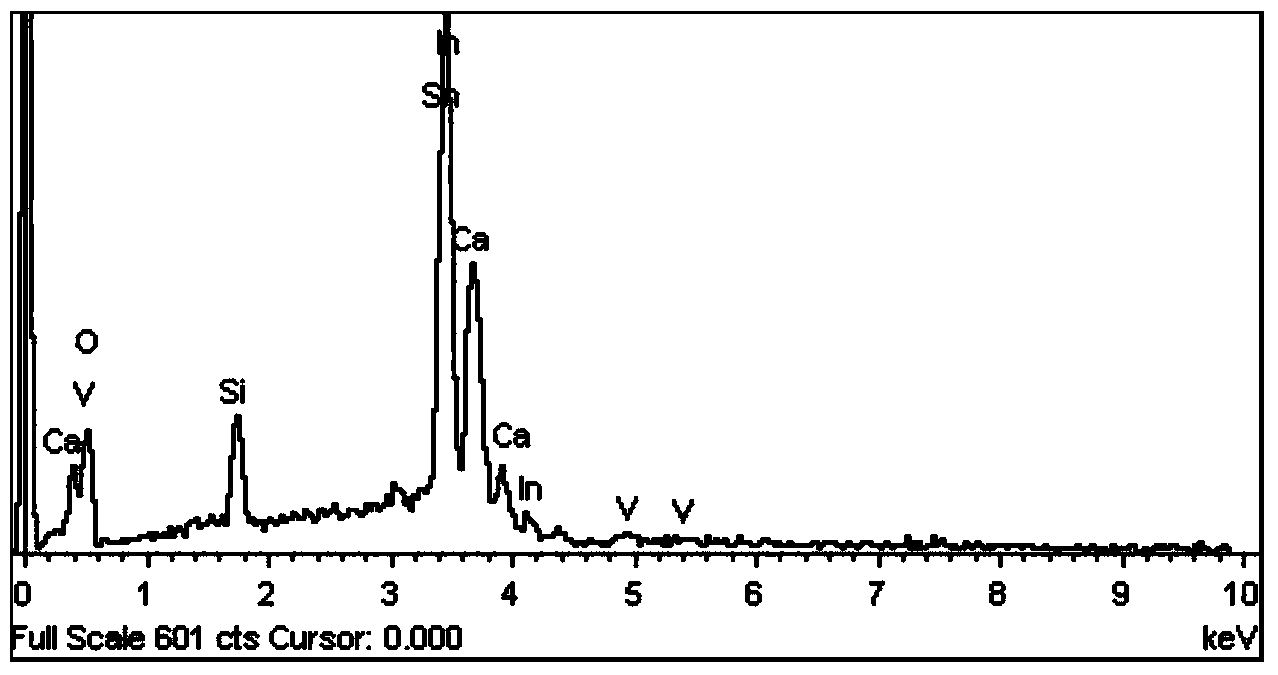

[0032] figure 1 It is the XRD spectrum of the vanadium dioxide flake thin fi...

Embodiment 2- Embodiment 4

[0037] According to the experimental parameters in Table 1, referring to the method of Example 1, vanadium dioxide flake films can be obtained.

[0038] Table 1

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com