Method for preparing regenerated cellulose fiber from fine corn fiber in corn starch milk production process

A technology of regenerated cellulose and corn fiber, which is applied in the direction of single-component cellulose rayon, fiber chemical characteristics, spinning solution preparation, etc. It can solve the problems of affecting the extraction and processing effect, high cost, and non-drying of fibers. Achieve the effects of increasing industrial utilization value, good textile mechanical properties, and avoiding preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

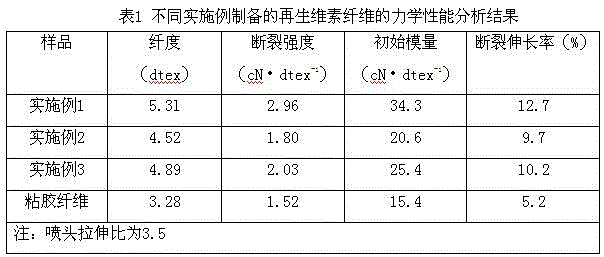

Examples

Embodiment 1

[0026] A method for preparing regenerated cellulose fiber from fine corn fiber in a cornstarch milk production process, comprising the steps of:

[0027] S1: Sieve out the fine fibers eluted after needle milling, sieving and washing by pressure, and use the obtained fine corn fiber slurry for later use;

[0028] S2: Add the butyl-3-methylimidazolium chloride salt solution with a moisture content of 2.0% into the dissolution kettle, heat to 100°C, then add the fine corn fiber slurry prepared in step S1, and add the fine corn fiber prepared in step S1 The weight ratio of fiber pulp to 1-butyl-3-methylimidazolium chloride salt solution is 1:6. After stirring, it will swell for 25 minutes to make it reach the maximum swelling ratio, and then stir and dissolve for 4 hours under the pressure of -0.2MPa to remove excess water to fully dissolve the cellulose to obtain a cellulose spinning solution;

[0029] S3: Use a multi-hole spinning device with a metering pump to carry out dry-je...

Embodiment 2

[0031] A method for preparing regenerated cellulose fiber from fine corn fiber in a cornstarch milk production process, comprising the steps of:

[0032] S1: Sieve out the fine fibers eluted after needle milling, sieving and washing by pressure, and use the obtained fine corn fiber slurry for later use;

[0033] S2: Add the butyl-3-methylimidazolium chloride salt solution with a moisture content of 1.5% into the dissolution kettle, heat to 100°C, then add the fine corn fiber pulp prepared in step S1, and add the fine corn prepared in step S1 The weight ratio of fiber pulp to 1-butyl-3-methylimidazolium chloride salt solution is 1:8. After stirring, it will swell for 30 minutes to make it reach the maximum swelling ratio, and then stir and dissolve for 5 hours under the pressure of -0.3MPa to remove excess water to fully dissolve the cellulose to obtain a cellulose spinning solution;

[0034] S3: Use a multi-hole spinning device with a metering pump to carry out dry-jet wet sp...

Embodiment 3

[0036] A method for preparing regenerated cellulose fiber from fine corn fiber in a cornstarch milk production process, comprising the steps of:

[0037] S1: Sieve out the fine fibers eluted after needle milling, sieving and washing by pressure, and use the obtained fine corn fiber slurry for later use;

[0038] S2: Add the butyl-3-methylimidazolium chloride salt solution with a moisture content of 2.5% into the dissolving kettle, heat to 100°C, then add the fine corn fiber pulp prepared in step S1, and add the fine corn prepared in step S1 The weight ratio of fiber pulp to 1-butyl-3-methylimidazolium chloride salt solution is 1:4. After stirring, it will swell for 20 minutes to make it reach the maximum swelling ratio, and then stir and dissolve under the pressure of -0.1MPa for 3 hours to remove excess water to fully dissolve the cellulose to obtain a cellulose spinning solution;

[0039] S3: Use a multi-hole spinning device with a metering pump to carry out dry-jet wet spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com