A kind of ultra-low shrinkage industrial yarn of creep-resistant polyester and its preparation method

A technology of ultra-low shrinkage and creep resistance, applied in the direction of single-component copolyester artificial filaments, bundles of newly extruded filaments, conjugated synthetic polymer artificial filaments, etc., to improve hydrolysis resistance, expand The scope of application and the effect of increasing the relative molecular mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

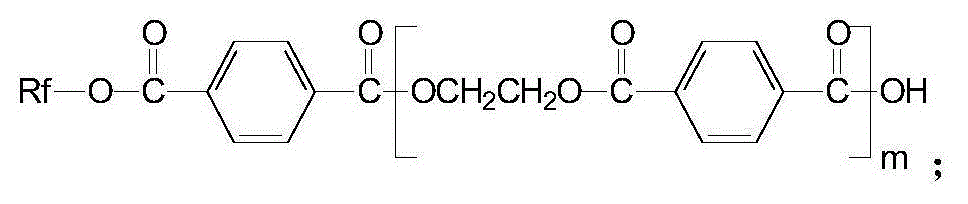

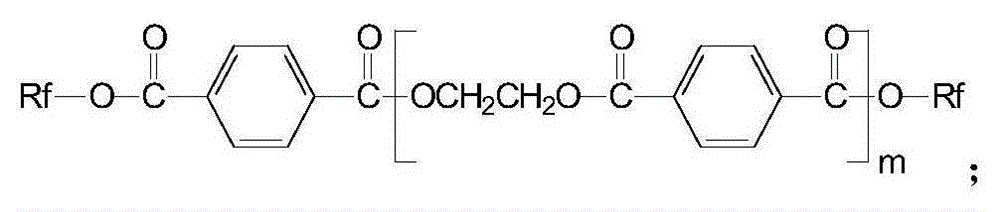

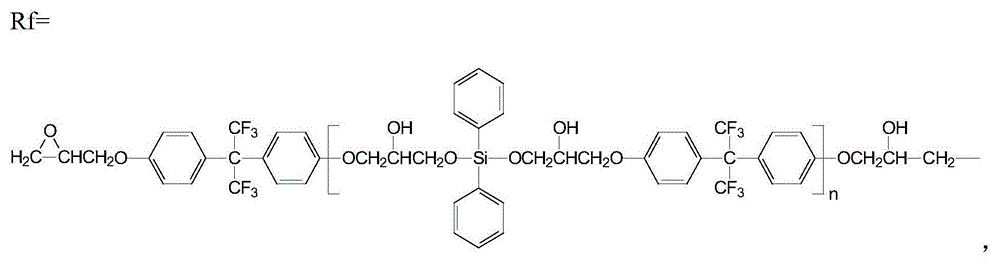

Method used

Image

Examples

Embodiment 1

[0055] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0056] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 1.5% of 15mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl) ethylene] diphenol mass, at room temperature Stir the reaction for 16h; then cool to room temperature, then add 30% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol with anhydrous carbonic acid Sodium-saturated 5mol / L sodium hydroxide solution, stirred and reacted at room temperature for 10h; then extracted with chloroform, and the resulting organic phase was evaporated to remove chloroform and excess epichlorohydrin to obtain a thick liquid, which was added to anhydrous Recrystallization in ethanol to obtain crystals of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether;

[0057] Preparation of ...

Embodiment 2

[0065] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0066] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 2.0% 10mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 18 hours; cool to room temperature, then add 40% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol with anhydrous sodium carbonate Saturated 3mol / L sodium hydroxide solution, stirred and reacted at room temperature for 15h; then extracted with chloroform, the resulting organic phase was evaporated to remove chloroform and excess epichlorohydrin to obtain a thick liquid, which was added to absolute ethanol Medium recrystallization, namely obtain the crystal of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether;

[0067] Preparation of fl...

Embodiment 3

[0075] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0076] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 1.8% of 12mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 17h; cool to room temperature, then add 35% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol with anhydrous sodium carbonate Saturated 4mol / L sodium hydroxide solution, stirred and reacted at room temperature for 13h; then extracted with chloroform, the resulting organic phase was evaporated to remove chloroform and excess epichlorohydrin to obtain a thick liquid, which was added to absolute ethanol Medium recrystallization, namely obtain the crystal of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether;

[0077] Preparation of fluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com