Aluminum plastic film package material for lithium battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

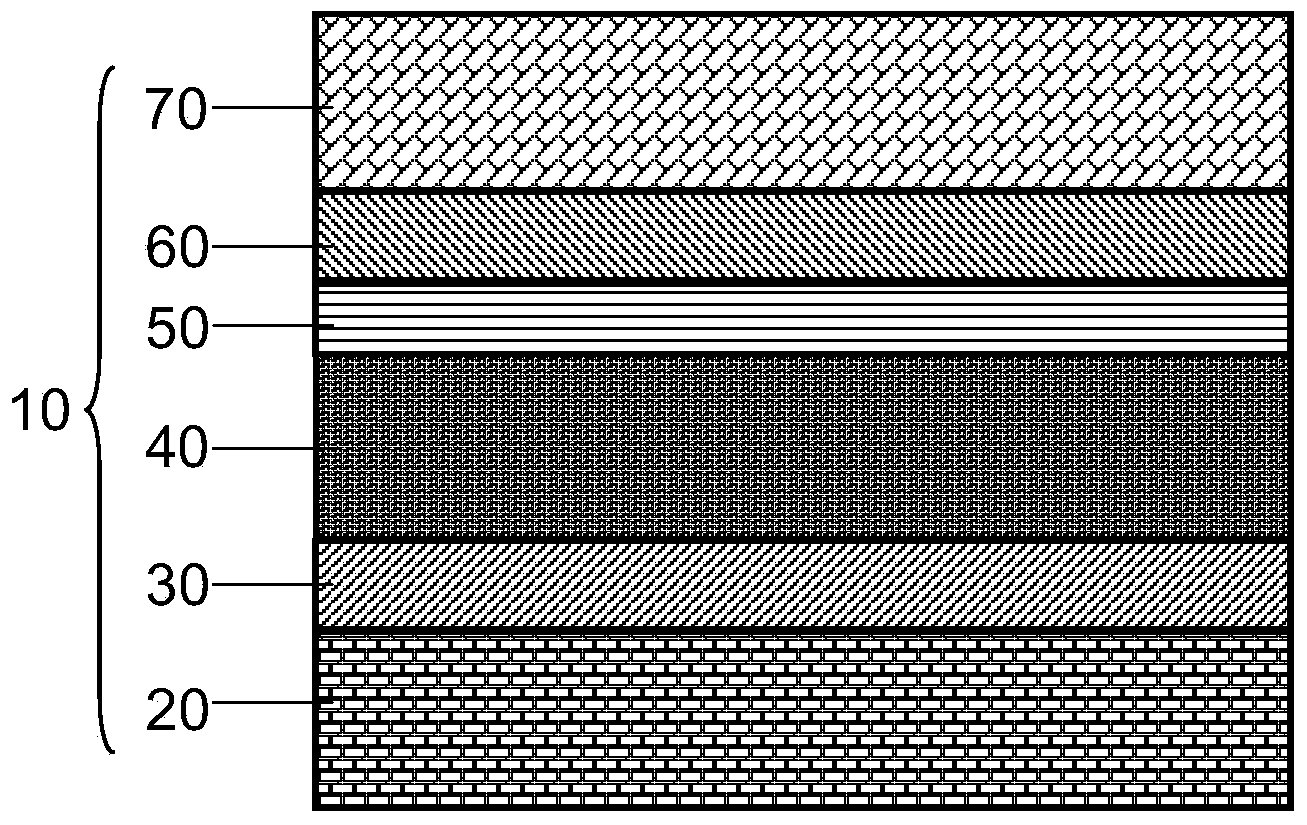

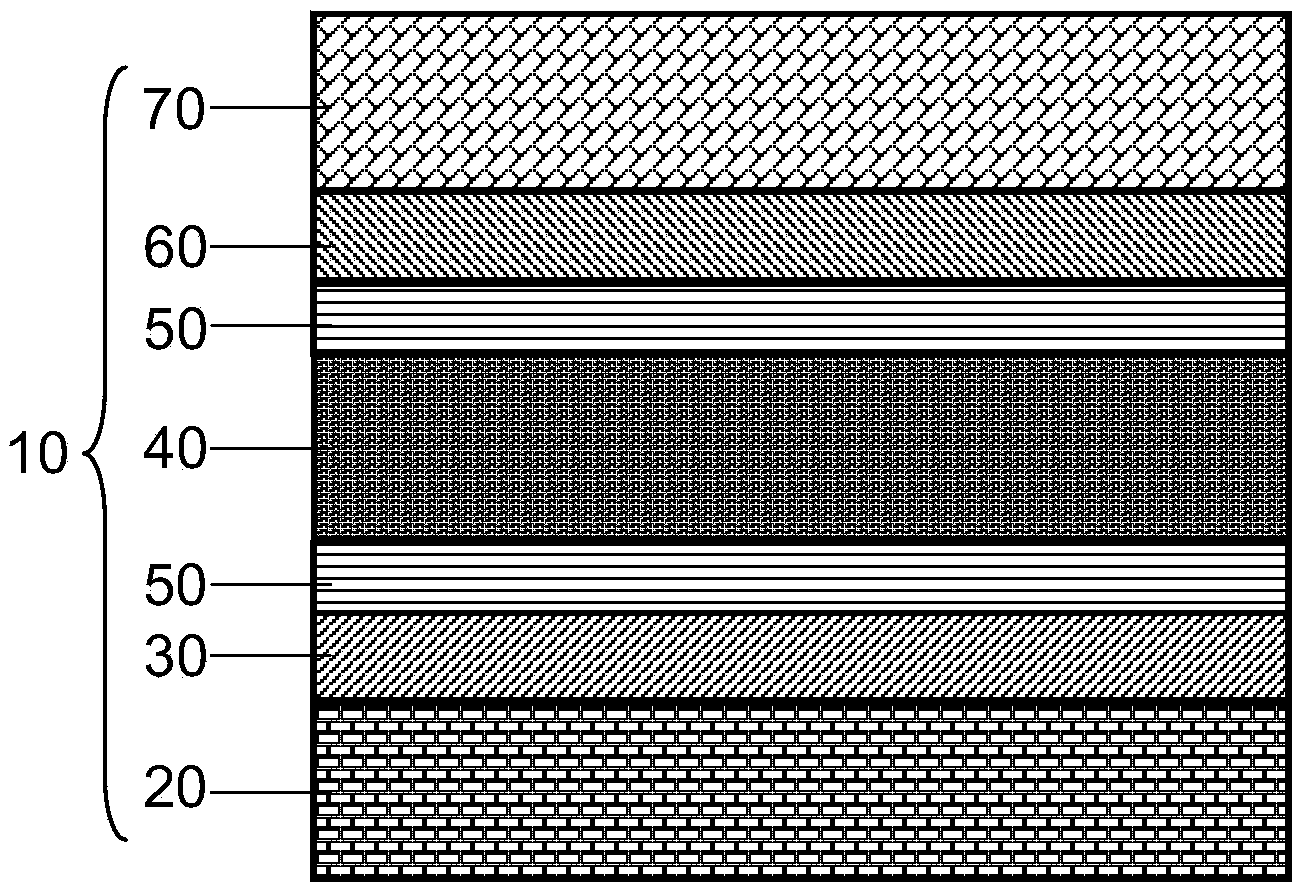

Method used

Image

Examples

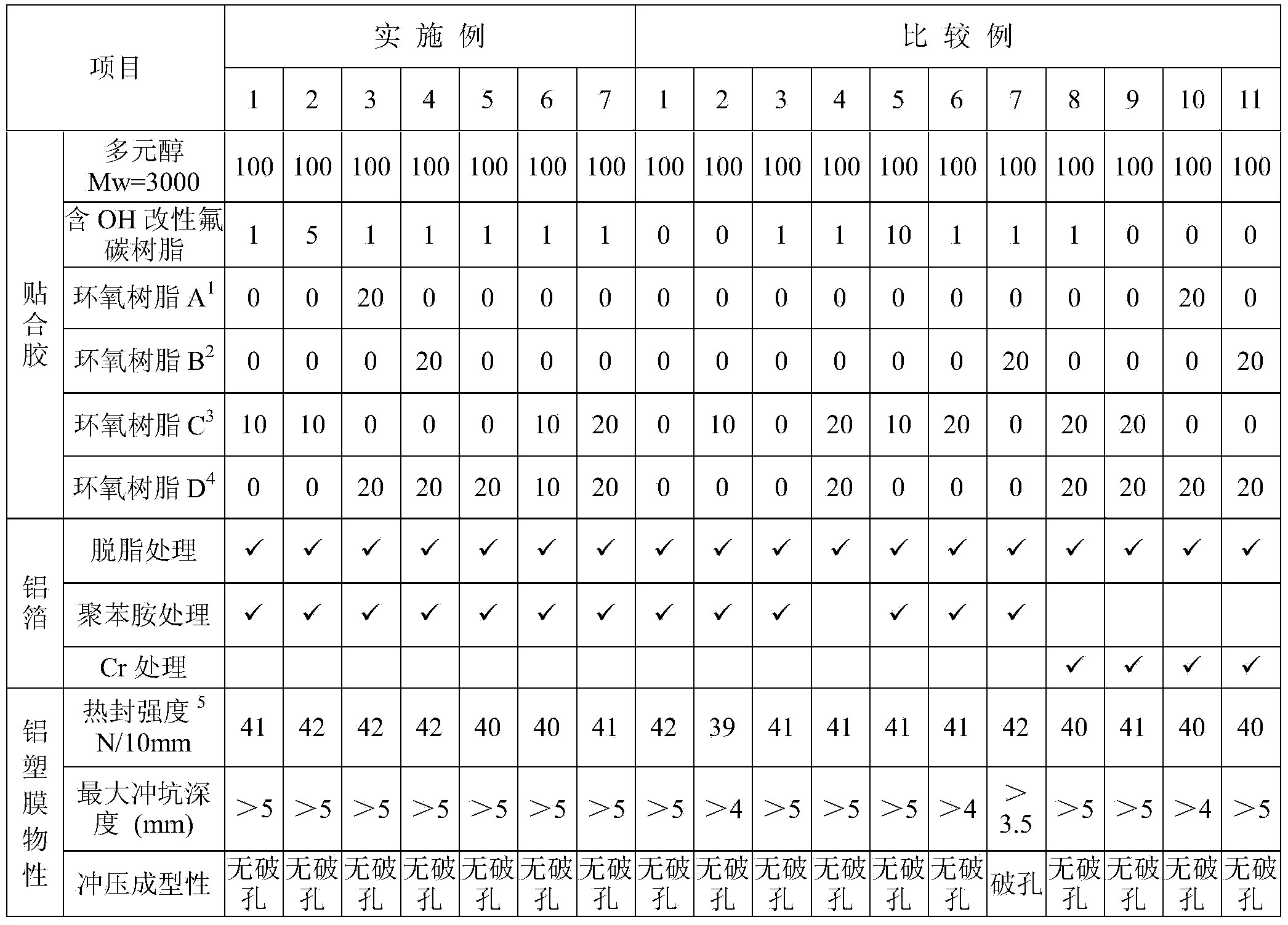

Embodiment 1

[0096] Add 100 parts by weight of polyol (product of Nan Ya Plastics Co., Ltd., Mw=3000), 1 part by weight of OH-containing modified fluorocarbon resin, and add (organotin T12) catalyst, antioxidant-1010 and solvent in a four-necked beaker, After mixing and heating to 80° C., adding metered toluene diisocyanate (TDI) and continuously stirring, reacting for 5-8 hours, and obtaining fluorine-containing polyurethane polyol after cooling.

[0097] The above-mentioned fluorine-containing polyurethane polyol was mixed with 10 parts by weight of novolac biphenyl formaldehyde epoxy resin (produced by Nanya Plastics Co., Ltd.) and multifunctional isocyanate to obtain fluorine-containing polyurethane resin bonding adhesive.

[0098] Aluminum plastic film production:

[0099] (1) Adopting a nylon film with a thickness of 25 microns as the substrate layer;

[0100] (2) Adopting a polypropylene film with a thickness of 40 microns as the inner layer;

[0101] (3) Adopt degreasing treatmen...

Embodiment 2

[0107] Using the adhesive composition in Table 1, the fluorine-containing polyurethane polyol in Example 1 was synthesized with 5 parts by weight of OH-containing modified fluorocarbon resin, and the rest of the conditions for making the aluminum-plastic film were the same as in Example 1.

[0108] The physical properties of the prepared aluminum-plastic film were tested, and the results are shown in Table 1.

Embodiment 3

[0110] Using the adhesive composition of Table 1, the fluorine-containing polyurethane resin adhesive of Example 1 is mixed with 20 parts by weight of bisphenol A epoxy resin and 20 parts by weight of novolac phenol formaldehyde epoxy resin, and the rest are made of aluminum plastic The membrane conditions are all the same as in Example 1.

[0111] The physical properties of the prepared aluminum-plastic film were tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com