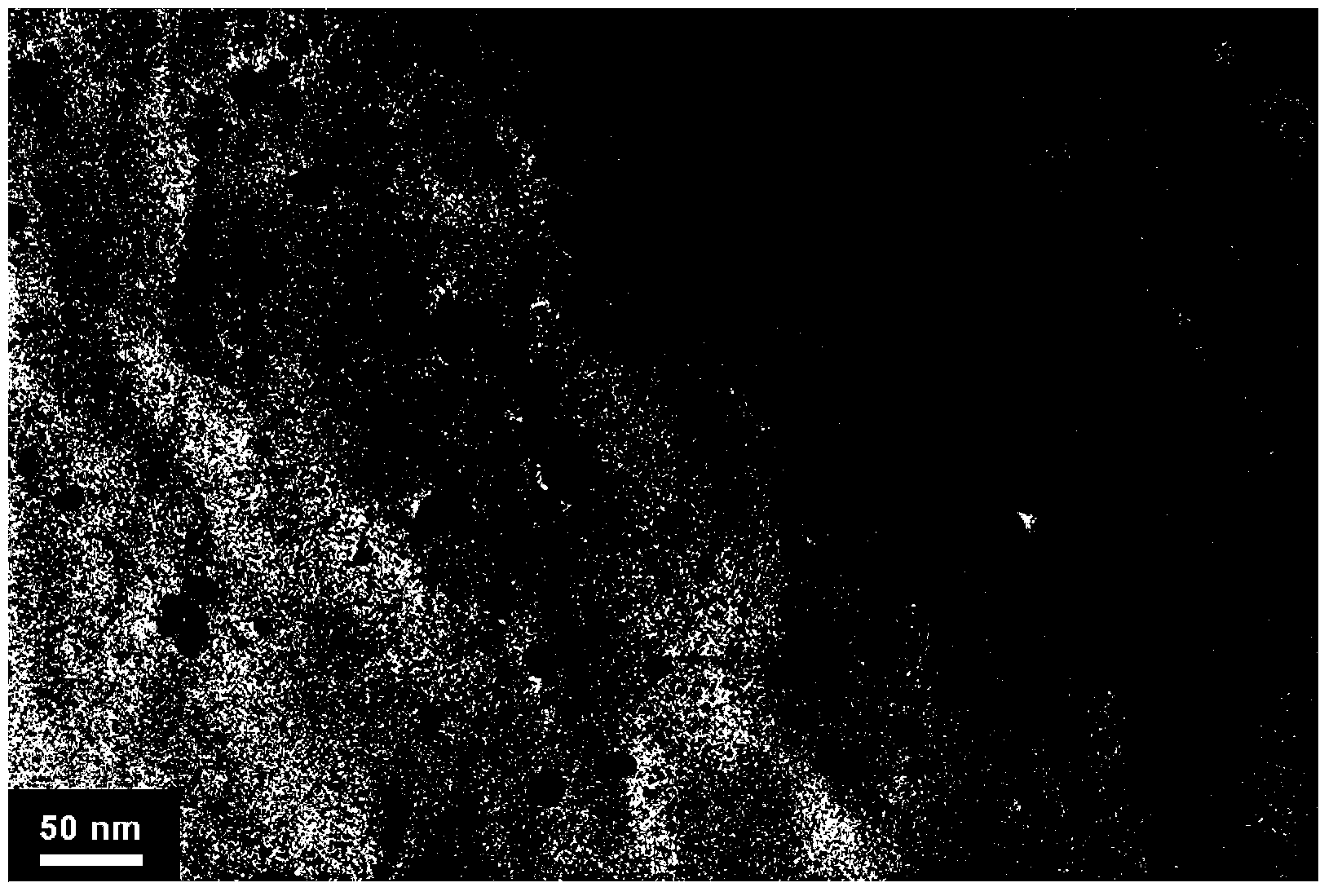

Nanometer silver colloid solution and preparation method thereof

A technology of colloidal solution and nano-silver, which is applied in the field of nanotechnology and fine chemical industry, can solve the problems of small nano-silver particle size and high surface energy, and achieve the effects of short cycle, strong stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

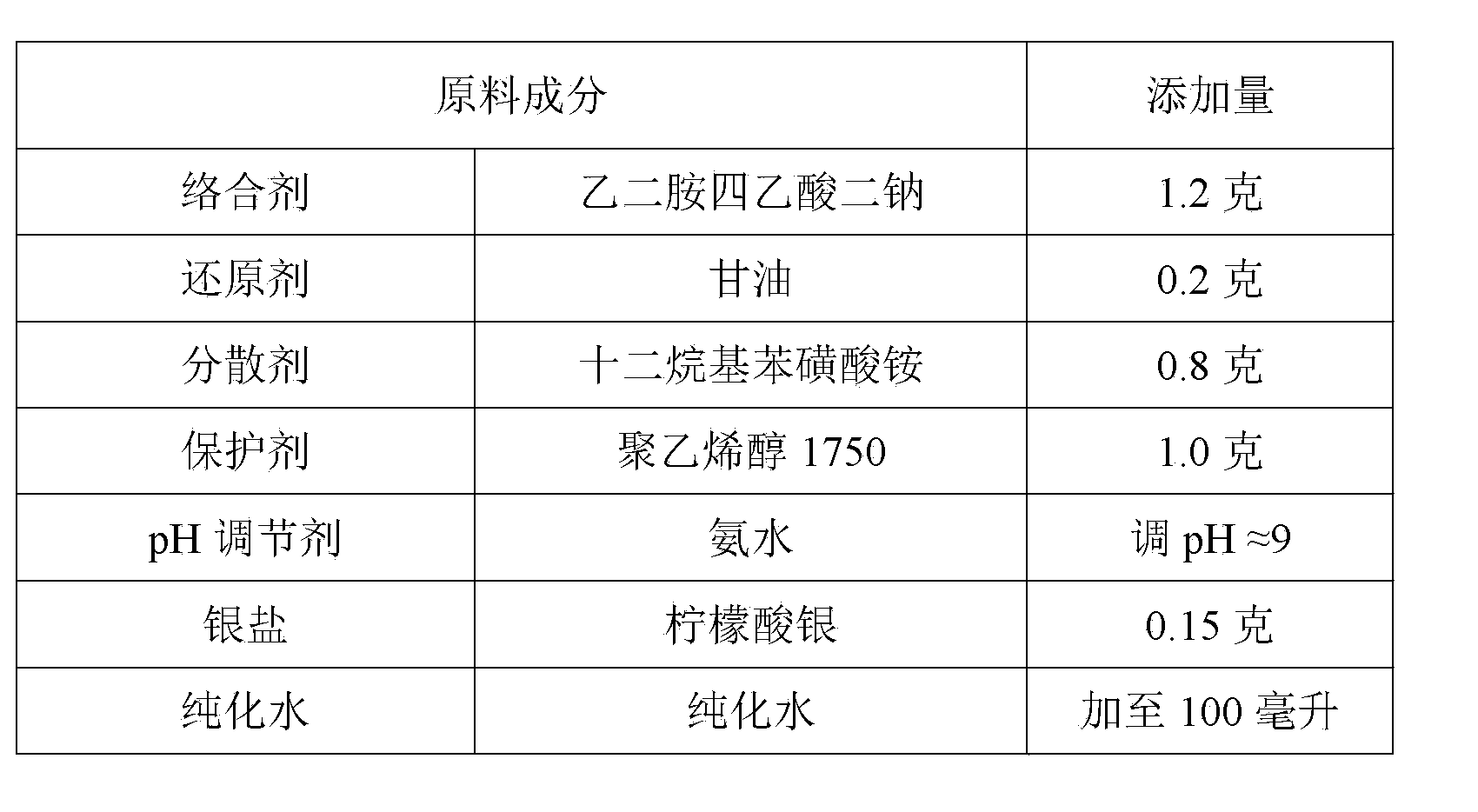

Embodiment 1

[0025] Raw materials and ratio:

[0026]

[0027] Preparation:

[0028] (1) According to the mass percentage, ammonia water was prepared into a solution with a concentration of 2%, ammonium dodecylbenzenesulfonate was prepared into a 10% solution, and polyvinyl alcohol 1750 was prepared into a 5% solution for later use.

[0029] (2) Add disodium edetate, glycerin, ammonium dodecylbenzenesulfonate solution and polyvinyl alcohol 1750 solution into the reactor, add purified water to 95 ml, and stir to dissolve. Then add ammonia solution to adjust the pH to about 9; then add silver citrate, stir to dissolve into a uniform transparent solution, then add purified water to 100 ml. .

[0030] (3) Raise the water temperature, and leave it to stand at 40 degrees Celsius for 8 hours to obtain the target nano-silver colloidal solution.

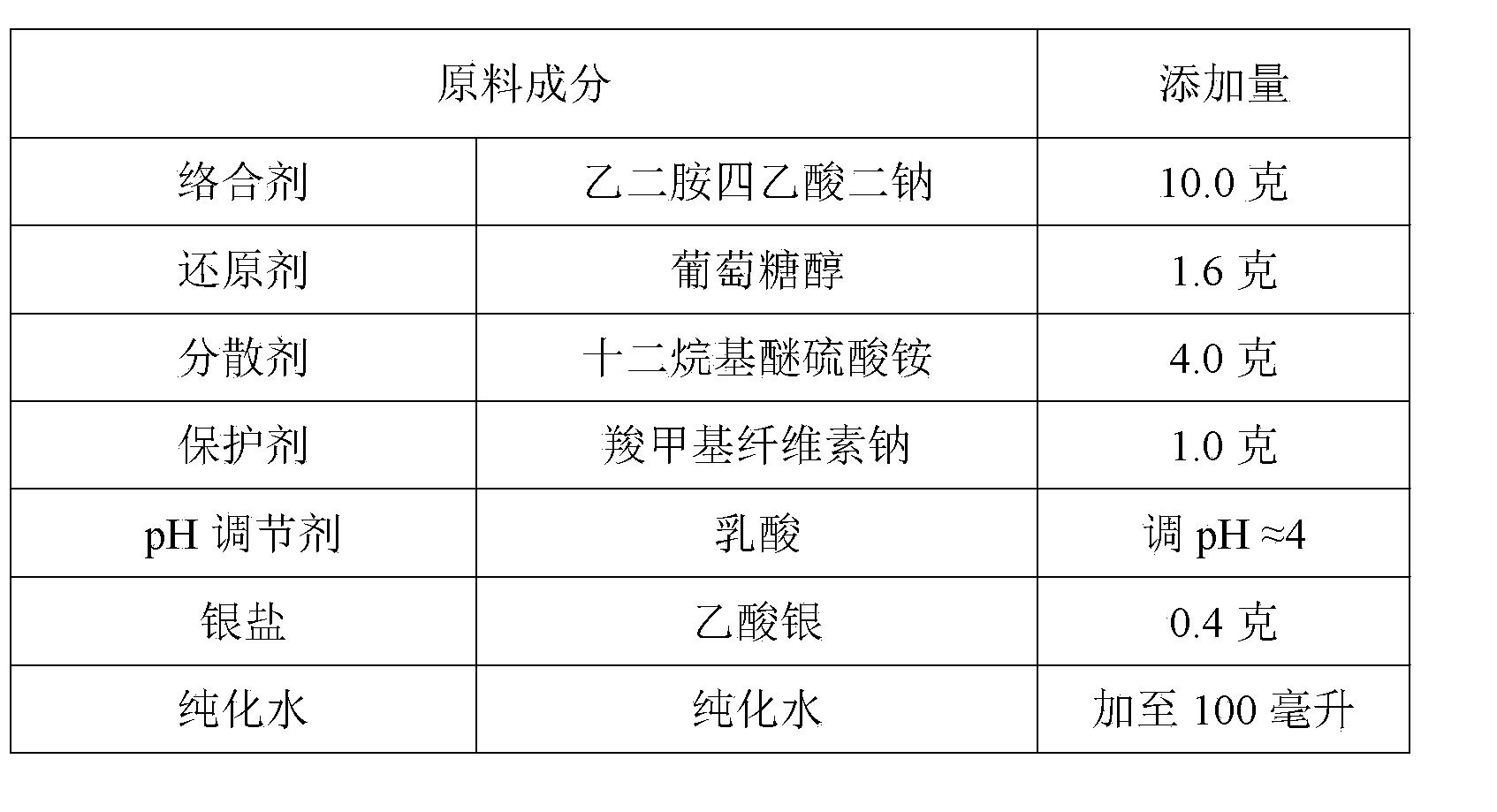

Embodiment 2

[0032] Raw materials and ratio:

[0033]

[0034] Preparation:

[0035] (1) According to mass percentage, prepare ammonium lauryl ether sulfate into a 10% solution, and sodium carboxymethylcellulose into a 5% solution for later use.

[0036] (2) Add disodium edetate, glucitol, ammonium lauryl ether sulfate solution and sodium carboxymethylcellulose solution into the reactor, add purified water to 95 ml, and stir to dissolve. Then add lactic acid to adjust the pH to about 4; then add silver acetate, stir to dissolve into a uniform transparent solution, then add purified water to 100 ml. .

[0037] (3) Airtightly stand and age at 60 degrees Celsius for 16 hours to obtain the target nano-silver colloid solution.

Embodiment 3

[0039] Raw materials and ratio:

[0040]

[0041] Preparation:

[0042] (1) According to mass percentage, boric acid was prepared into a 10% solution, ammonium dodecylsulfonate was prepared into a 10% solution, and Carbomer 2020 was prepared into a 1% solution for later use.

[0043] (2) Add sodium hexametaphosphate, mannitol, ammonium dodecylsulfonate solution and carbomer 2020 solution into the reactor, add purified water to 95 ml, and stir to dissolve. Then add boric acid solution to adjust the pH to about 6.5; then add silver nitrate, stir to dissolve into a uniform transparent solution, then add purified water to 100 ml.

[0044] (3) Airtightly stand and age at 50 degrees Celsius for 24 hours to obtain the target nano-silver colloid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com