Microwave-assisted synthesis method of nano fluorapatite powder

A fluoroapatite powder and microwave-assisted technology is applied in the synthesis field of nano-fluoroapatite powder and can solve the problems of complex process, high energy consumption, long reaction period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

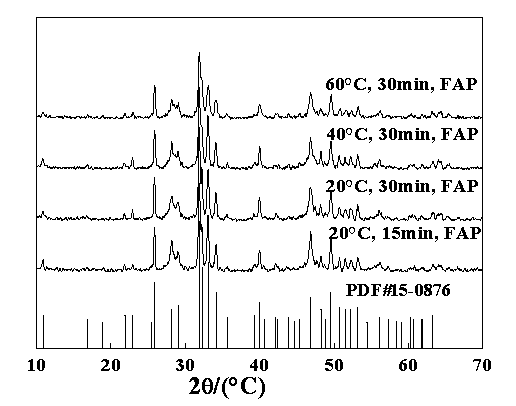

Embodiment 1

[0022] (1) Dissolve 4.723 g calcium nitrate tetrahydrate in 50 mL water to make a concentration of 0.4 mol L -1 Calcium ion solution; 1.585 g diammonium hydrogen phosphate and 0.333 g ammonium fluoride were dissolved in 50 mL water to make a concentration of 0.24 mol L -1 Phosphate and 0.18 mol·L -1 A mixed solution of fluoride ions;

[0023] (2) Pour the mixture of calcium ions, phosphate and fluoride ions in step (1) into a three-necked flask. The pH of the reaction system is the natural pH of the mixture, and the reaction temperature is 60°C. Under stirring conditions, microwave synthesis for 30 min;

[0024] (3) When the temperature of the system dropped to room temperature after the reaction, the product was separated by centrifugation, washed three times with distilled water, dried in an oven at 80 °C for 12 h, and ground to obtain nano-fluoroapatite powder.

Embodiment 2

[0026] The preparation steps are the same as in Example 1, except that the temperature of the water bath in step (2) is changed to 40° C. to obtain nano-fluoroapatite powder.

Embodiment 3

[0028] The preparation steps are the same as in Example 1, except that the temperature of the water bath in step (2) is changed to 20° C. to obtain nano-fluoroapatite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com