Preparation method for compound proton exchange membrane for high-temperature-resisting fuel cell

A proton exchange membrane and fuel cell technology, which is applied to fuel cell parts, fuel cells, battery pack parts, etc., can solve the problems of lowering open circuit voltage, complicated preparation process, and leakage of phosphoric acid, so as to improve proton conductivity The efficiency, the preparation method is simple, and the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of the precursor of silicon nanoparticle

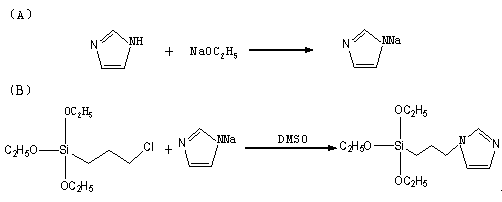

[0031] Such as figure 1 As shown in: (A) Add imidazole and sodium ethoxide with a molar ratio of 1:1 into a round-bottomed flask containing an appropriate amount of absolute ethanol, stir magnetically at 70°C for 8 hours, remove the solvent by rotary evaporation, and remove the solvent at 50°C After drying under vacuum for 6 hours, imidazole sodium was obtained; (B) γ-chloropropyltriethoxysilane and imidazole sodium with a molar ratio of 1:1 were added to a round bottom flask containing an appropriate amount of anhydrous methanol, and a white solid After precipitation, continue to stir at room temperature for 24 hours to fully react, stop the reaction, filter the mixed solution, and remove the solvent by rotary evaporation to obtain the precursor of silicon nanoparticles.

[0032] Such as figure 1 As shown, the reaction product of imidazole sodium and γ-chloropropyltriethoxysilane in step (B) con...

Embodiment 2

[0033] Embodiment 2: Preparation of PBI composite proton exchange membrane doped with 5.0% silicon nanoparticles

[0034] (1) Dissolve 0.95g of polybenzimidazole (PBI) in 10ml of dimethyl sulfoxide (DMSO), heat properly until the polymer is completely dissolved, and the system becomes a brown transparent solution;

[0035](2) Weigh 0.015 mol of sodium ethoxide and 0.015 mol of imidazole respectively, add to a round bottom flask containing 10 ml of absolute ethanol, stir magnetically at 70°C for 8 hours, remove the solvent ethanol by rotary evaporation, and vacuum at 50°C After drying for 6 hours, imidazole sodium was obtained; 0.01mol imidazole sodium and 0.01mol gamma-chloropropyl triethoxysilane were respectively added to a round-bottomed flask containing 10 mL of anhydrous methanol, and magnetically stirred at room temperature for 24 hours to fully react. Stop the reaction, filter the mixed solution, and remove the solvent by rotary evaporation to obtain the precursor of si...

Embodiment 3

[0037] Embodiment 3: Preparation of PBI composite proton exchange membrane doped with 10% silicon nanoparticles

[0038] Dissolve 0.90g of polybenzimidazole (PBI) in 10ml of dimethyl sulfoxide (DMSO), heat properly until the polymer is completely dissolved, and the system becomes a brown transparent solution, add 0.1g of the precursor of silicon nanoparticles, and drop hydrochloric acid to adjust The pH of the mixed solution was 2, and it was stirred at room temperature for 6 hours; other operations were the same as in Example 2, the doping ratio of the composite film was 10%, and the thickness was 90 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com