Mosaic ceramic drawing die and making method thereof

A wire drawing die and inlaid splicing technology, applied in the field of inlaid spliced ceramic wire drawing dies and its preparation, can solve the problems of difficult grinding in the exit area, low impact resistance and toughness, thermal fatigue cracks, etc., and reduce the production process. And the effect of cost, hardness and wear resistance improvement, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

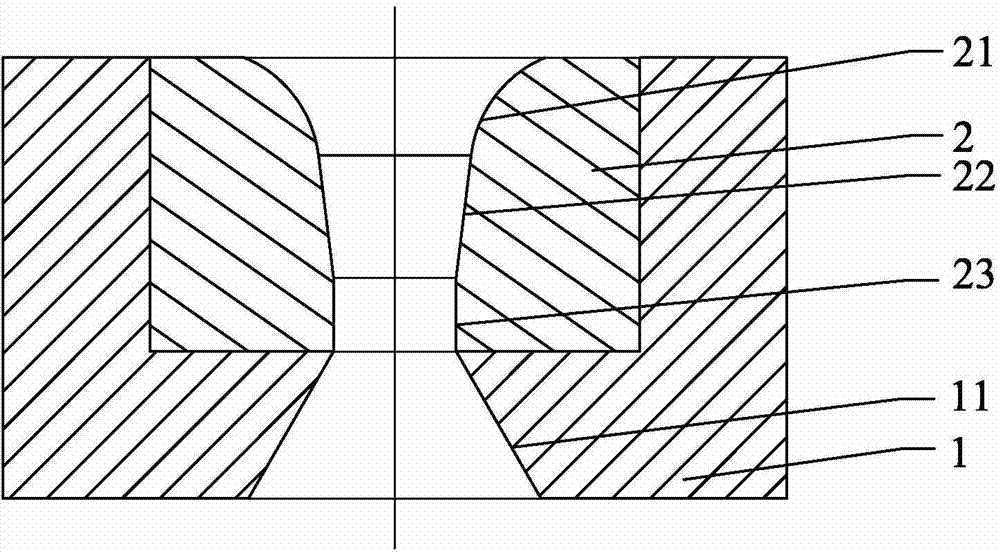

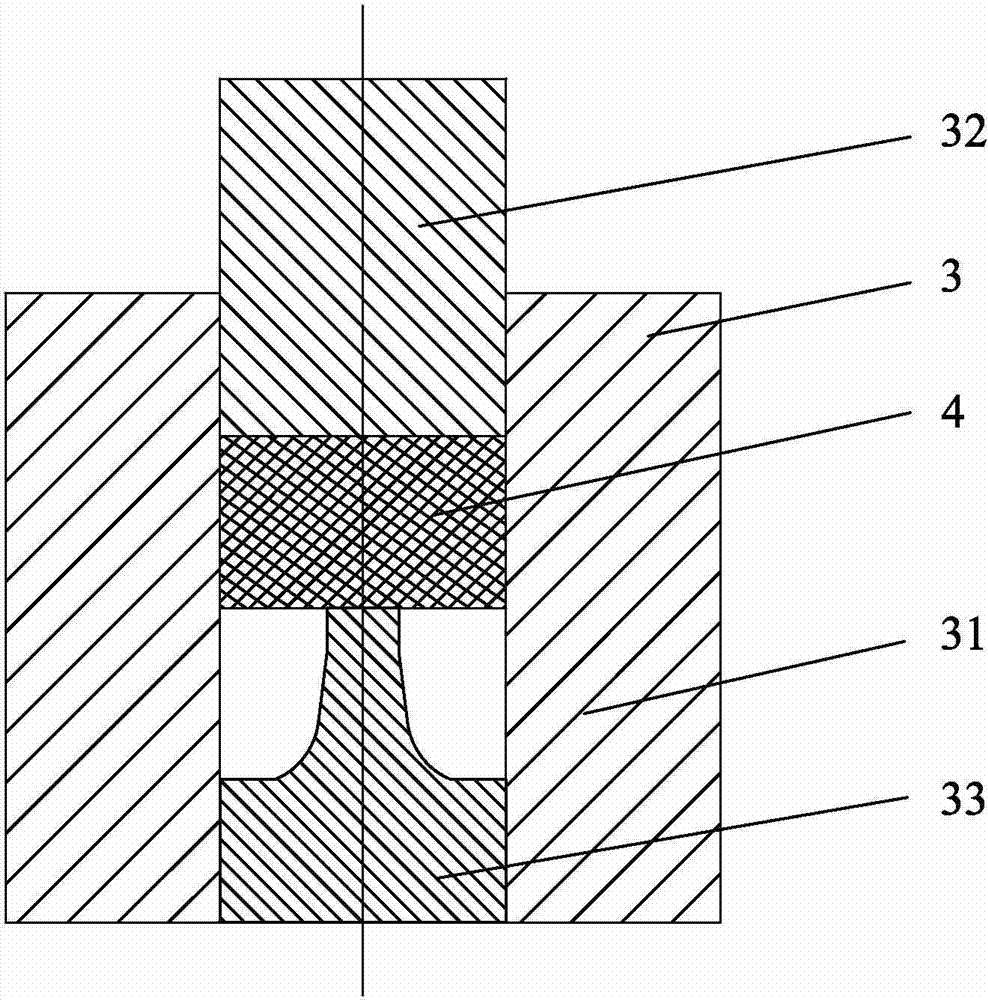

[0031] The core 2 material is a kind of Al 2 O 3 as the matrix, adding ZrO 2 and Y 2 O 3 The formed ternary eutectic nano-ceramics. First set the molar ratio to 65mol% Al 2 O 3 , 19mol% ZrO 2 , 16mol Y 2 O 3 The three commercially available nanopowders were uniformly mixed in a ball mill. The mixed nano-ceramic powder is put into a cylindrical mold made of graphite, and is slowly pressurized to 200 MPa on an ordinary press, maintained for 5 minutes, and slowly unloaded to take out the pressed cylindrical ceramic body. Then, the ceramic body was put into a common heating furnace and slowly heated to 1450° C., kept for 2 hours, and taken out to obtain a ceramic sintered body. The ceramic sintered body is put into a graphite mold for vacuum melting at a melting temperature of 1900°C, then cooled to room temperature with the furnace, and the ceramic material is taken out to obtain a eutectic ceramic body 4 with extremely high wear resistance.

[0032] The eutectic ceram...

Embodiment 2

[0034] The core 2 material is a kind of Al 2 O 3 as the matrix, adding ZrO 2 and Y 2 O 3 The obtained ternary eutectic nano-ceramic. First, according to the molar ratio of reaction products, it is 64mol% Al 2 O 3 , 18mol% ZrO 2 , 18molY 2 O 3 Calculate Weighing Al 2 (NO 3 ) 9H 2 O: 65%, ZrOCl 2 ·8H 2 O: 20%, Y (NO 3 ) 3 ·6H 2 O: 15% three kinds of raw materials, after mixing the three kinds of raw materials, add them into a mixed solvent of absolute ethanol and distilled water, first add a small amount of polyethylene glycol as a dispersing agent in the solvent to prevent the three kinds of nano powders from being added Agglomeration of the body occurs, and the solution should be continuously stirred during the addition of the drug. After stirring for 50 minutes, the solution was heated in a 65° C. water bath for 5 hours, then a small amount of ammonia water was added to the solution, and the solution was allowed to stand for 1 day. Since the powder will be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com