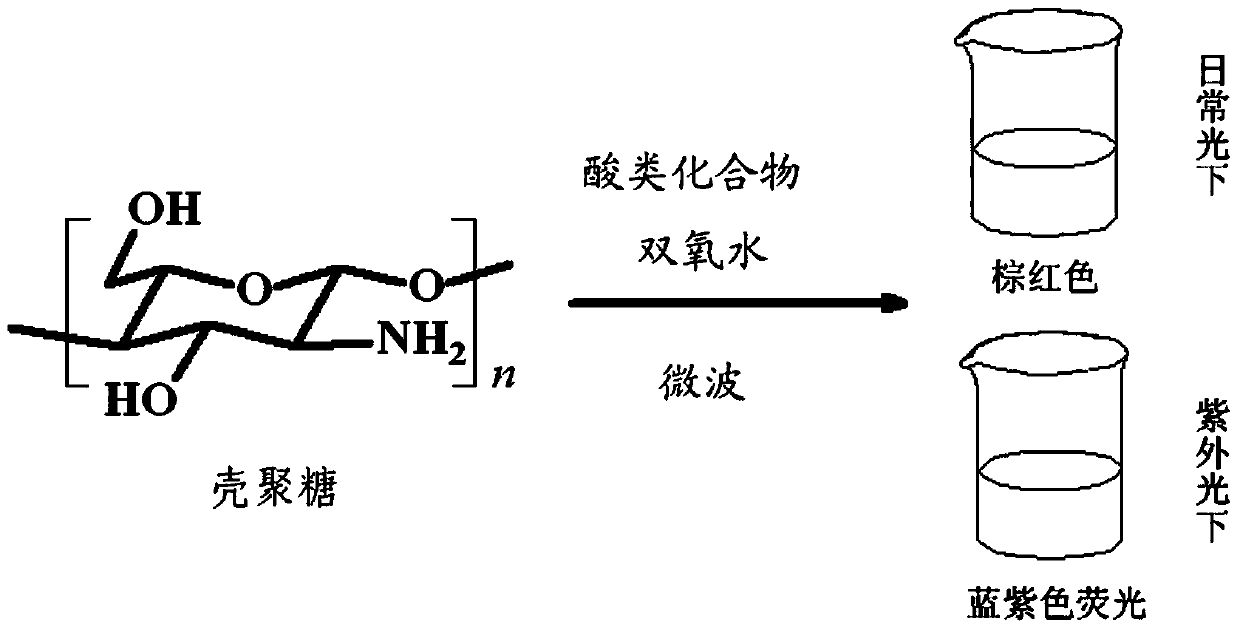

Method for preparing high purity carbon quantum dots by using microwave method

A technology of carbon quantum dots and microwave method, which is applied in the direction of nanocarbon, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effect of reducing environmental pressure, easy operation and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

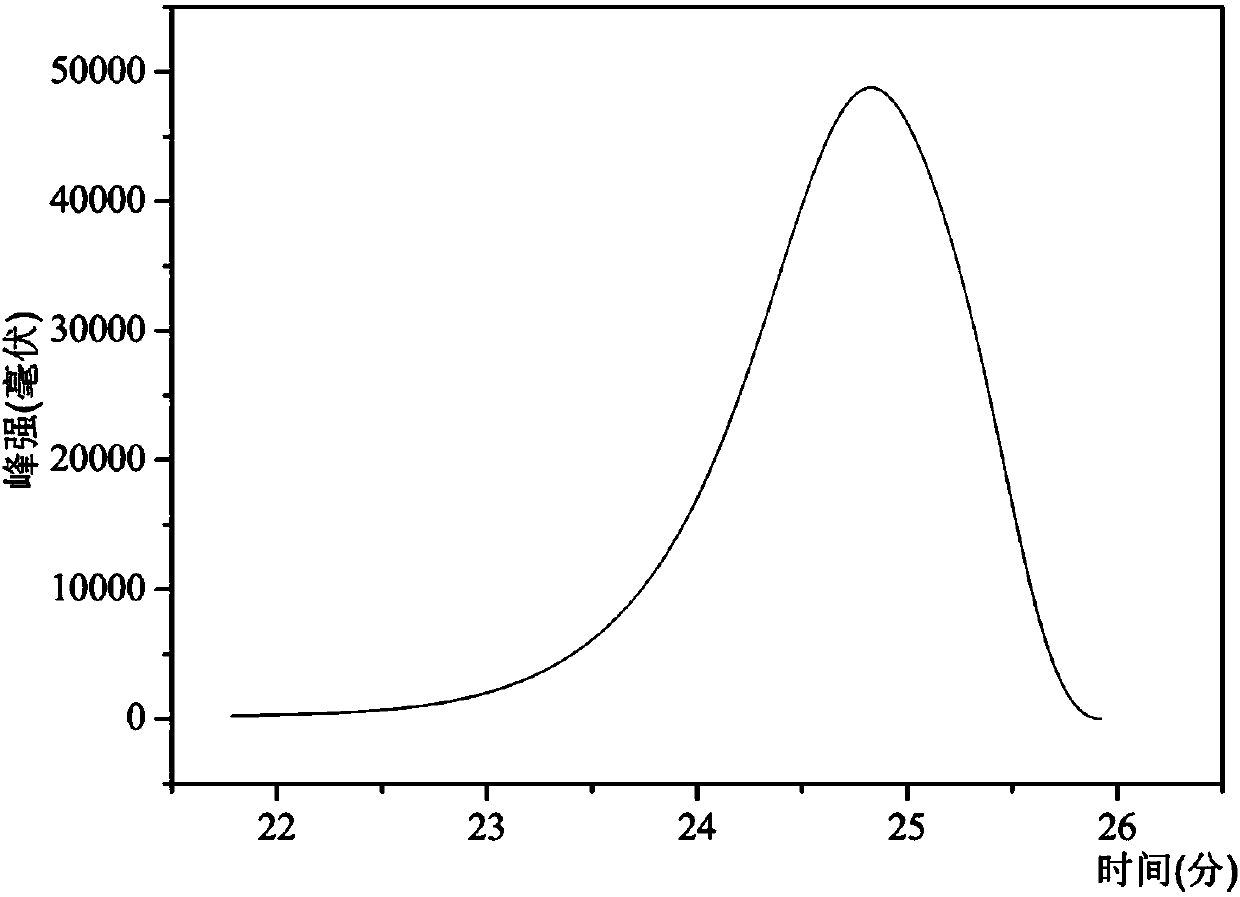

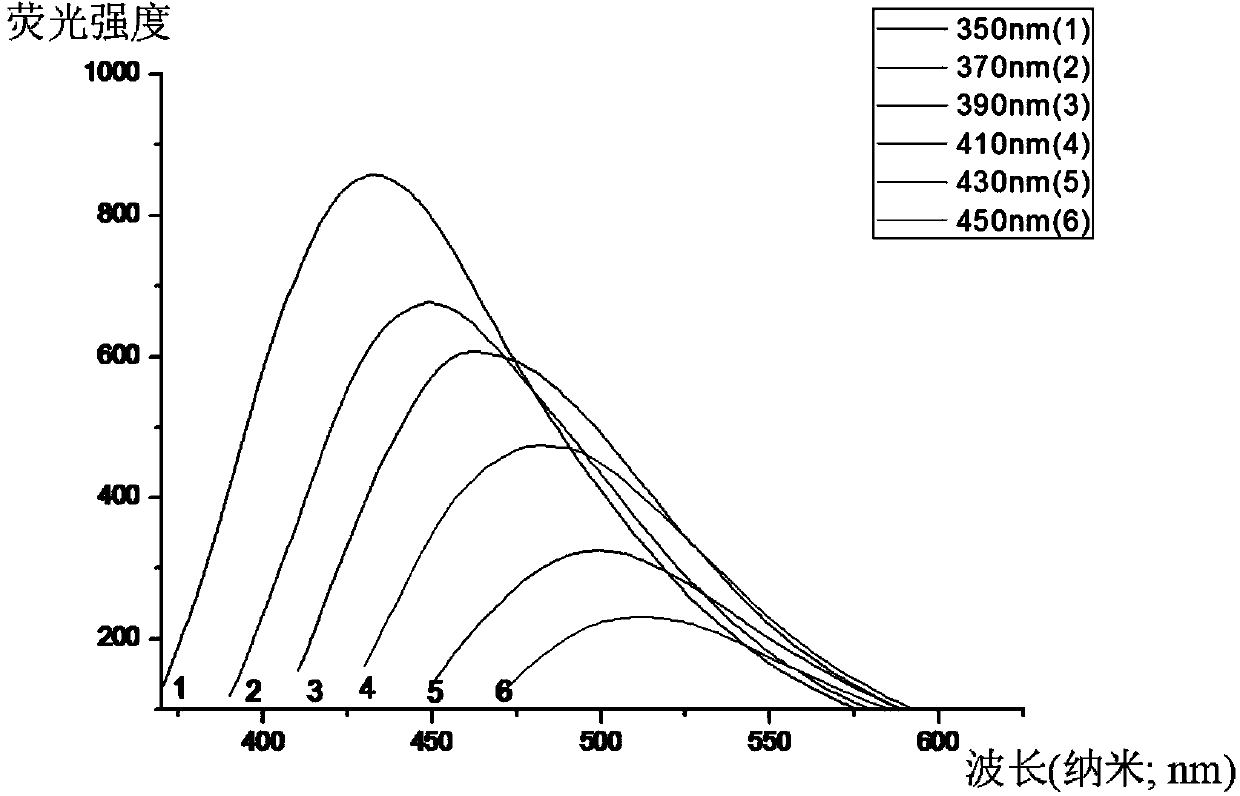

[0032] (1) The deacetylation degree of 2.0g is 98%, and the molecular weight distribution index (M w / M n ) of 1.20 chitosan powder was dissolved in 120mL of acetic acid (HAc) solution with a mass concentration of 0.5%, and 1.2mL of hydrogen peroxide (H 2 o 2 ), stirred at normal temperature for 5 minutes to form a uniform and transparent colorless viscous liquid;

[0033] (2) Place the viscous liquid above in a microwave reactor (model: HKWB-10RB) for microwave degradation. The parameters are set as follows: microwave power 700W, temperature 80°C, microwave time 70 minutes, colorless viscous liquid Become a uniform transparent light yellow liquid;

[0034] (3) Put the above-mentioned uniform and transparent light yellow liquid in a microwave reactor (model: HKWB-10RB) to continue the reaction, and reset the microwave parameters. The parameters are set as follows: microwave power 900W, temperature 110°C, microwave time 70 minutes, increase Microwave power and reaction temp...

Embodiment 2

[0039] (1) The deacetylation degree of 2.0g is 98%, and the molecular weight distribution index (M w / M n ) is 1.24 chitosan powder dissolved in 180mL mass concentration of 30% hydrochloric acid (HCl) solution, and add 6mL of hydrogen peroxide (H 2 o 2 ), stirred at normal temperature for 20 minutes, forming a uniform and transparent colorless viscous liquid;

[0040] (2) Place the viscous liquid above in a microwave reactor (model: HKWB-10RB) for microwave degradation. The parameters are set as follows: microwave power 800W, temperature 100°C, microwave time 120 minutes, colorless viscous liquid Become a uniform transparent light yellow liquid;

[0041] (3) Put the above uniform and transparent light yellow liquid in a microwave reactor (model: HKWB-10RB) to continue the reaction, reset the microwave parameters, the parameters are set as follows: microwave power 1100W, temperature 300°C, microwave time 120 minutes, increase Microwave power and reaction temperature, open t...

Embodiment 3

[0046] (1) The deacetylation degree of 3.0g is 95%, the molecular weight distribution index (M w / M n ) is 1.17 chitosan powder dissolved in 180mL of nitric acid (HNO 3 ) solution, and add 6mL of hydrogen peroxide (H 2 o 2 ), stirred at normal temperature for 10 minutes to form a uniform and transparent colorless viscous liquid;

[0047] (2) Place the viscous liquid above in a microwave reactor (model: HKWB-10RB) for microwave degradation. The parameters are set as follows: microwave power 800W, temperature 70°C, microwave time 50 minutes, colorless viscous liquid Become a uniform transparent light yellow liquid;

[0048] (3) Put the above-mentioned uniform and transparent light yellow liquid in a microwave reactor (model: HKWB-10RB) to continue the reaction, and reset the microwave parameters. The parameters are set as follows: microwave power 1000W, temperature 90°C, microwave time 60 minutes, increase Microwave power and reaction temperature, open the action, the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com