Method for removing boron and metal impurities for polysilicon melting in electron-beam furnace

An electron beam furnace and metal impurity technology, applied in chemical instruments and methods, non-metallic elements, silicon compounds, etc., to achieve the effect of improving the ability of volatilization and removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

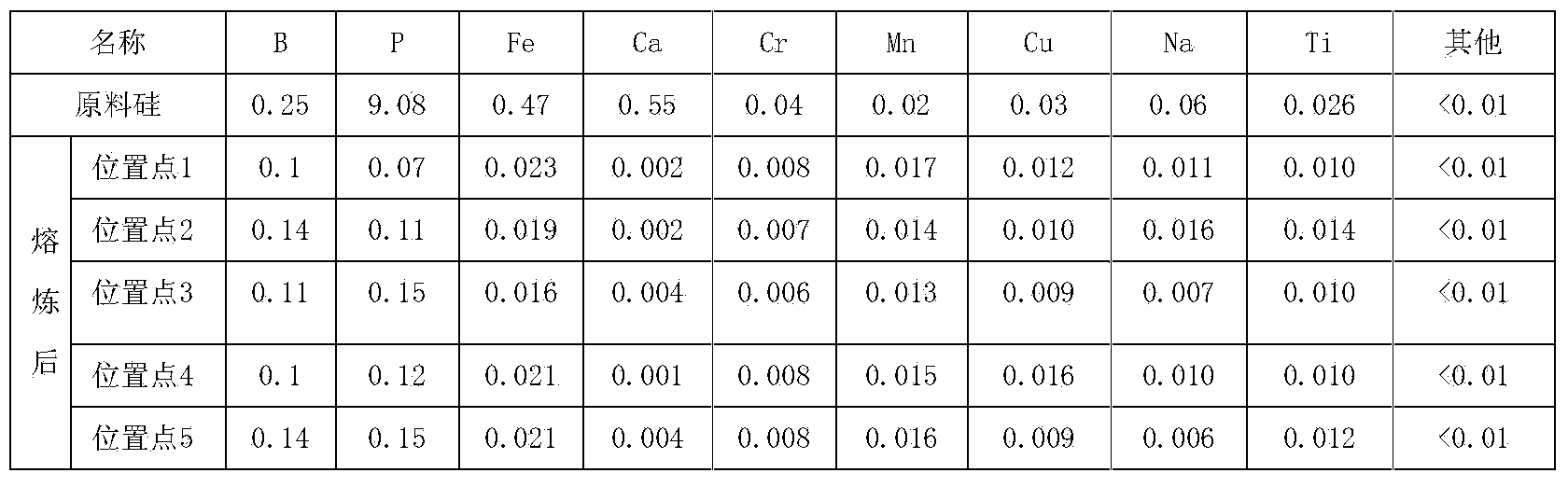

[0022] Embodiment 1: A method for removing boron and metal impurities by smelting polysilicon in an electron beam furnace, characterized in that: the method is: take boron content of 0.25ppmw, phosphorus content of 9.08ppmw, iron content of 0.47ppmw, copper content of 0.03ppmw Silicon block, the particle size of silicon block is less than 25mm. The silicon block is acid-washed with a mixed dilute solution of hydrochloric acid and hydrofluoric acid, and a pure water lotion is used to test the conductivity of the pure water after the lotion is close to the conductivity of the pure water, and the lotion is completed.

[0023] Put the lotioned silicon block into a high-temperature resistance furnace, rapidly raise the temperature to 600°C at a rate of 5°C / min, keep it warm for 4 hours, stop heating, and cool down naturally. When the furnace temperature drops to room temperature, stop the furnace and discharge. A light blue color appears on the surface of the silicon block, indicat...

Embodiment 2

[0027]Embodiment 2: A method for removing boron and metal impurities by electron beam furnace smelting polysilicon, characterized in that: the method is: take boron content of 0.25ppmw, phosphorus content of 9.08ppmw, iron content of 0.47ppmw, copper content of 0.03ppmw Silicon block, the particle size of silicon block is less than 25mm. The silicon block is acid-washed with a mixed dilute solution of hydrochloric acid and hydrofluoric acid, and a pure water lotion is used to test the conductivity of the pure water after the lotion is close to the conductivity of the pure water, and the lotion is completed.

[0028] Put the lotioned silicon block into a high-temperature resistance furnace, rapidly raise the temperature to 900°C at a rate of 5°C / min, keep it warm for 2 hours, stop heating, and cool down naturally. When the furnace temperature drops to room temperature, stop the furnace and discharge. A light blue color appears on the surface of the silicon block, indicating tha...

Embodiment 3

[0032] Embodiment 3: A method for removing boron and metal impurities by smelting polysilicon in an electron beam furnace, characterized in that: the method is: take boron content of 0.25ppmw, phosphorus content of 9.08ppmw, iron content of 0.47ppmw, copper content of 0.03ppmw Silicon block, the particle size of silicon block is less than 25mm. The silicon block is acid-washed with a mixed dilute solution of hydrochloric acid and hydrofluoric acid, and a pure water lotion is used to test the conductivity of the pure water after the lotion is close to the conductivity of the pure water, and the lotion is completed.

[0033] Put the lotion-treated silicon block into a high-temperature resistance furnace, rapidly raise the temperature to 900°C at a rate of 5°C / min, keep it warm for 3 hours, stop heating, and cool down naturally. When the furnace temperature drops to room temperature, stop the furnace and discharge. A light blue color appears on the surface of the silicon block, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com