Preparation method of magnetic porous adsorbent by suspension polymerization

A porous adsorbent, suspension polymerization technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as damage and high toxicity of chlorophenol, achieve good magnetic response performance, increase adsorption The effect of high capacity and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. A method for preparing magnetic porous adsorbent by suspension polymerization, the preparation method is carried out according to the following steps:

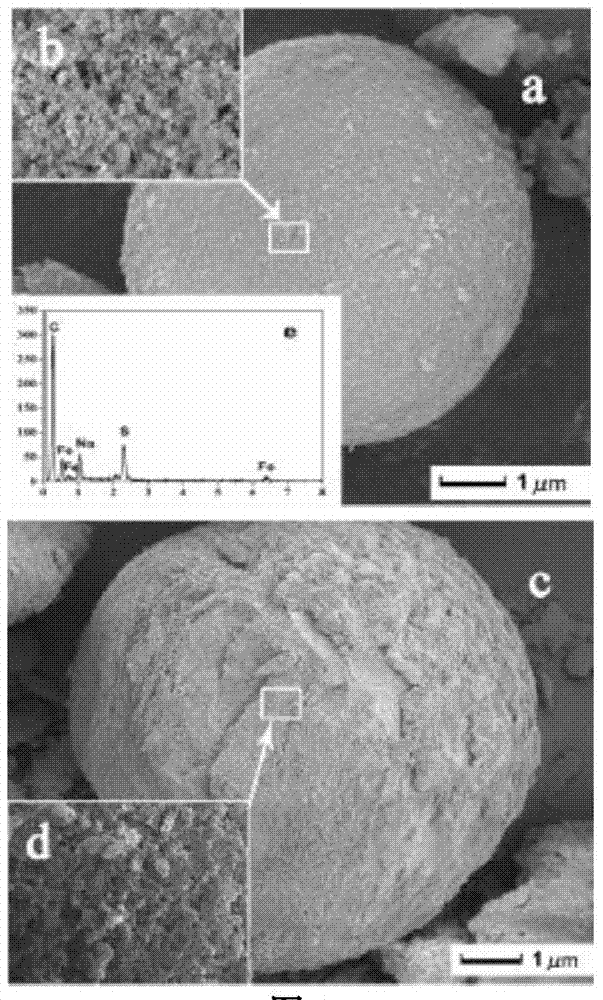

[0035] (1) Synthesis of porous phenethyl-divinylbenzene (St-DVB) nanoparticles:

[0036]Dissolve 5 ml styrene (St), 7.5 ml divinylbenzene (DVB), 0.25 g azobisisobutyronitrile (AIBN) and 6.3 ml cyclohexanol in 4.2 ml toluene to form an organic phase, and 1.5 g chloride Sodium (NaCl) and 0.9 g of hydroxyethylcellulose (HEC) were dissolved in 70 ml of deionized water to form the aqueous phase. After thorough stirring, the two phases were mixed under ultrasonic conditions for 15 min to form an emulsion. The emulsion was transferred to a 250 ml three-neck flask equipped with a condenser and a nitrogen device, stirred for 1 h under the protection of nitrogen, and then the temperature was raised from room temperature to 70 °C. The reaction was continued for 24 h under high-speed stirring at 800 rpm / min. Finally, a porous...

Embodiment 2

[0049] 1. A method for preparing magnetic porous adsorbent by suspension polymerization, the preparation method is carried out according to the following steps:

[0050] (1) Synthesis of porous phenethyl-divinylbenzene (St-DVB) nanoparticles:

[0051] Dissolve 5.3 ml of styrene (St), 7.8 ml of divinylbenzene (DVB), 0.2 g of azobisisobutyronitrile (AIBN) and 6.5 ml of cyclohexanol in 4.3 ml of toluene to form an organic phase, and 1.57 g of chlorine Sodium chloride (NaCl) and 1.1 g of hydroxyethylcellulose (HEC) were dissolved in 75 ml of deionized water to form the aqueous phase. After thorough stirring, the two phases were mixed under ultrasonic conditions for 30 min to form an emulsion. The emulsion was transferred to a 250 ml three-neck flask equipped with a condenser and a nitrogen device, stirred for 2 h under the protection of nitrogen, and then the temperature was raised from room temperature to 70 °C. The reaction was continued for 24 h under a high-speed stirring co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com