Novel preparation method for monodisperse porous polymer nano microcapsule

A technology of porous polymers and nano-microcapsules, which is applied in the field of organic porous materials and can solve problems such as increasing the application range of porous polymer microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

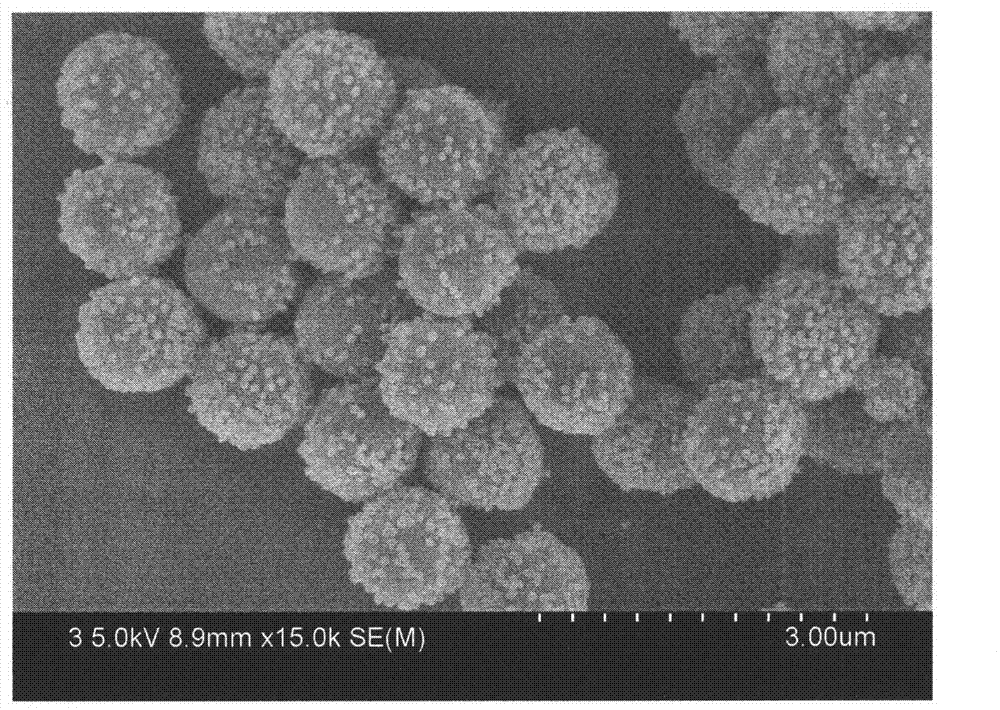

[0037] 1. Preparation of PMAA-nuclear microspheres

[0038]Take 0.04g of azobisisobutyronitrile (AIBN) and 2mL of α-methacrylic acid (MAA) into a 100mL two-necked flask, disperse them in 80mL of anhydrous acetonitrile, add zeolite, connect the thorn-type fractionation column and straight condenser and receiving bottle. Heat with a 100mL electric heating mantle, control boiling within 15 minutes, until about 40mL of acetonitrile is evaporated, stop heating, and complete the first polymerization; then take 10mL of the polymer after the first distillation in a flask, add 70mL of acetonitrile, and ultrasonically Make it evenly mixed, add 0.04g AIBN, and 2mL α-methacrylic acid monomer, conduct the second distillation, repeat the first polymerization process, stop heating when 40mL of acetonitrile is evaporated; finally take 10mL of the second distillation Put the polymer in the flask, add 70mL of acetonitrile, mix it evenly by ultrasonic, add 0.04g of AIBN, and 2mL of α-methacryli...

Embodiment 2

[0046] 1. Preparation of PMAA-nuclear microspheres

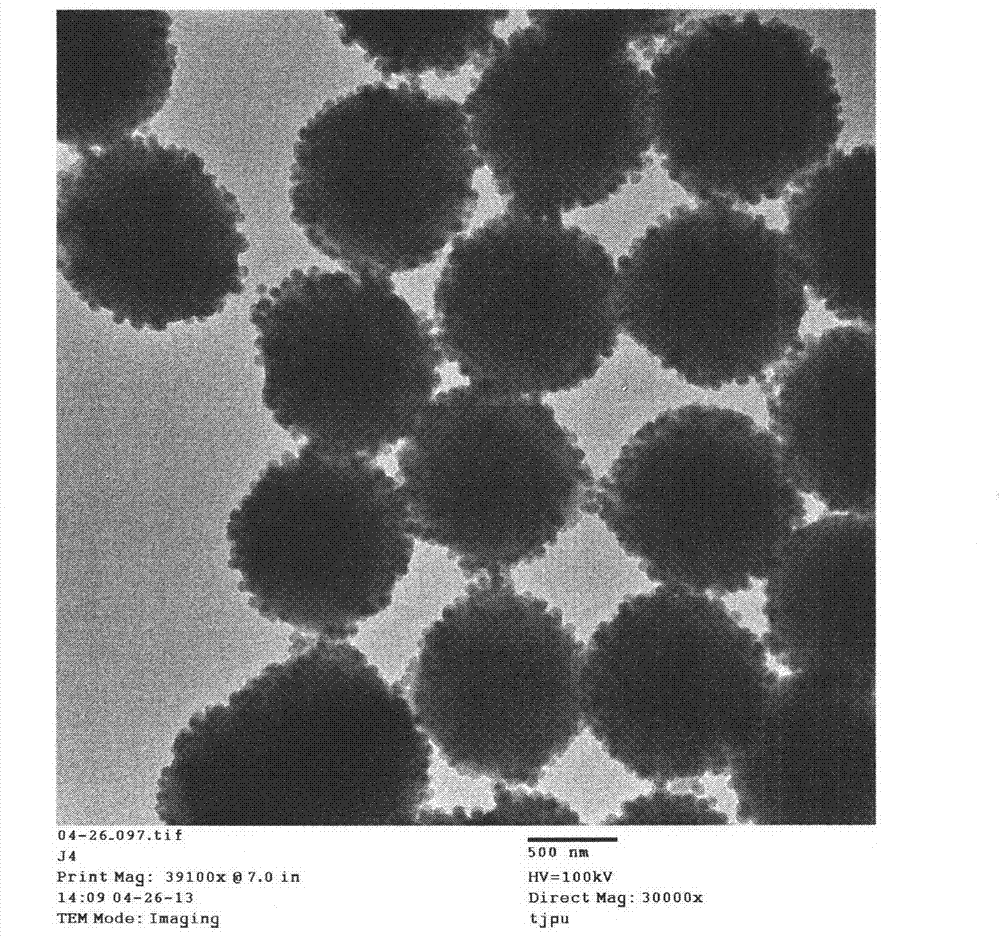

[0047] Take 0.04g of azobisisobutyronitrile (AIBN) and 5mL of α-methacrylic acid (MAA) into a 100mL two-necked flask, disperse in 80mL of anhydrous acetonitrile, add zeolite, connect the thorn-type fractionation column, straight condenser and receiving bottle. Heat with a 100mL electric heating mantle, control boiling within 30 minutes, and stop heating until about 40mL of acetonitrile is evaporated. After the product was cooled, the product was centrifuged at 8000 rpm, and after being washed three times continuously with anhydrous acetonitrile, the obtained PMAA microspheres had a particle size of 500 nm, and were dispersed in 40 mL of anhydrous acetonitrile for subsequent use.

[0048] 2. Preparation of SiO2 crown microspheres

[0049] Add 50mL ethanol, 1mL distilled water and 1.2mL concentrated ammonia water into a 100mL flask, stir at 25°C for 20min, add 1mL TEOS, continue stirring for 5h, add APTES0.05mL, continue sti...

Embodiment 3

[0055] Steps 1, 2, and 3 are the same as in Example 2.

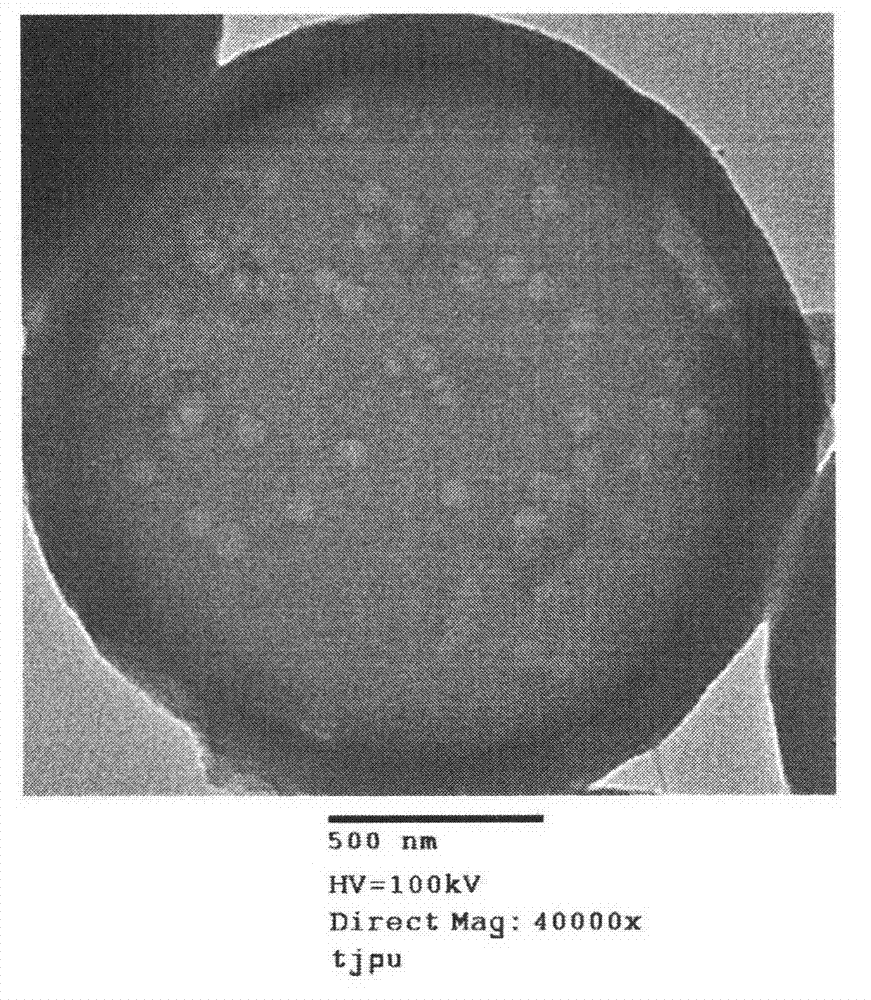

[0056] 4. Preparation of porous polymer nanocapsules

[0057] Using the core-corona microspheres with the strawberry structure prepared in step 3 as a template, measure 10mL into a 100mL two-necked flask, add 70mL of acetonitrile, fully sonicate, add AIBN 0.04g, 4-vinylpyridine (4-Vp) 0.02mL , 0.2 mL of hydroxyethyl methacrylate (HEMA) and 0.8 mL of ethylene glycol dimethacrylate (EGDMA) were subjected to seed distillation precipitation polymerization. Add zeolite, connect the thorny fractionation column, straight condenser and receiving bottle, heat with a 100mL electric heating mantle, control boiling within 15 minutes, until about 15mL of acetonitrile is evaporated, and stop heating. After the polymer product was suction-filtered with a G-6 sand core funnel, it was placed in a 100mL tetrafluoro beaker, and 40% HF solution was added, and after magnetic stirring for 1 hour, the SiO2 part was removed by etching. Pour t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com