Method for preparing SnO2 PC/CdS QDs composite photocatalyst with high-stability visible-light catalytic activity

A catalytic activity, visible light technology, applied in the field of material chemistry, can solve problems such as low utilization of visible light, and achieve the effect of improving migration and separation efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) FTO conductive glass with a thickness of 1.1 mm and a surface resistance of 15 Ω / sq was ultrasonically cleaned with acetone, absolute ethanol and pure water in turn, and dried with a hair dryer for use;

[0034] (2) SnCl 2 (10g), SbCl 3 (0.5g) Prepared as tin dioxide sol, the solvent is 100mL absolute ethanol, and a little concentrated hydrochloric acid is added dropwise until it is clear. SnCl in the sol 2 / SbCl 3 Mass ratio = 20:1, and keep magnetic stirring for later use;

[0035] (3) Insert the clean FTO conductive glass vertically into the sol of step (2) and soak for 5 minutes, slowly remove the infiltrated microsphere template at a certain pulling speed and dry it at room temperature. Repeat the above process 10 times to ensure that the tin dioxide sol fully infiltrates the FTO glass to obtain a SnO2 sol film;

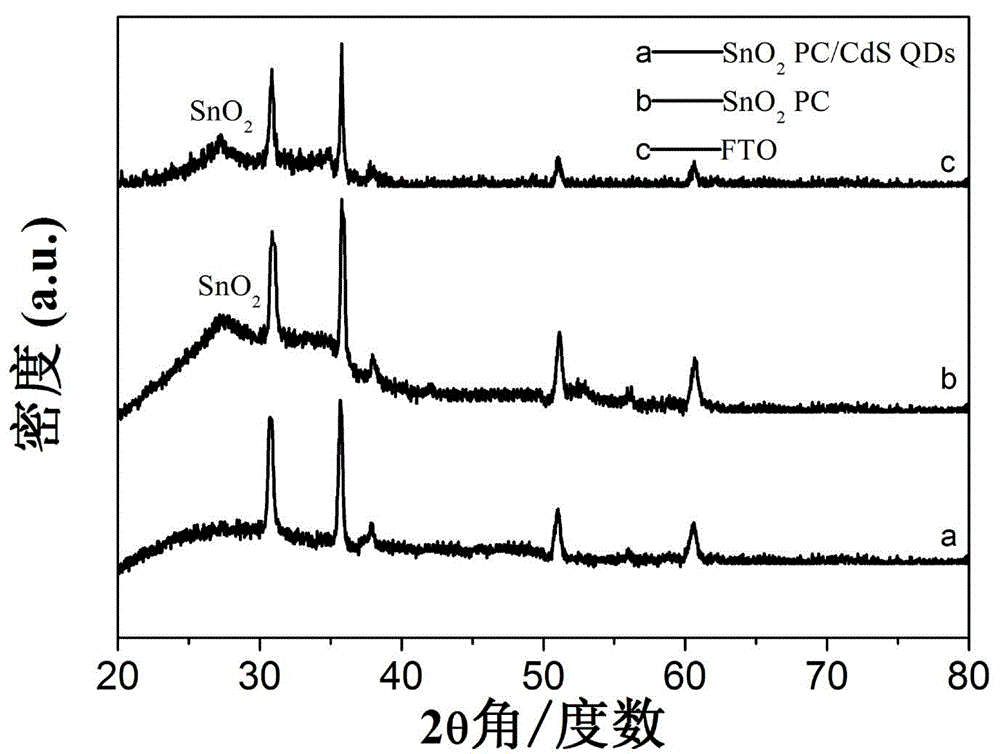

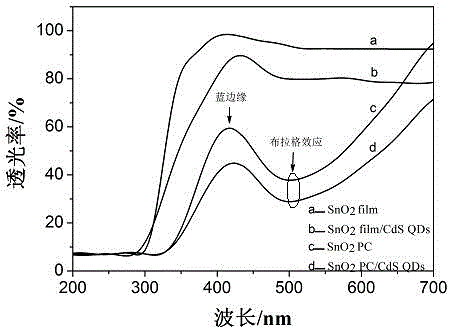

[0036] (4) The SnO prepared in step (3) 2 The sol film was calcined in a tube furnace at 450°C for 2h, and the heating rate during the calcining process wa...

Embodiment 2

[0039] A Highly Stable Visible Light Catalytic Activity SnO 2 The preparation method of PC / CdS photonic crystal structure composite photocatalyst, this method is to prepare SnO2 photonic crystal on FTO substrate by liquid deposition method, and then use continuous chemical water bath deposition method assisted by sonic digestion, and use CdS quantum dots for sensitivity And prepared a new type of SnO 2 PC / CdS photonic crystal structure. The method specifically includes the following steps:

[0040] (1) FTO conductive glass with a thickness of 1.1 mm and a surface resistance of 15 Ω / sq was ultrasonically cleaned with acetone, absolute ethanol and pure water in turn, and dried with a hair dryer for use;

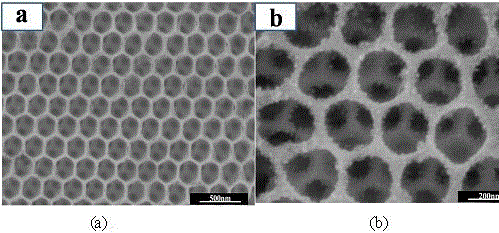

[0041] (2) The suspension of polystyrene microspheres with a size of 190nm and 5%wt is diluted with deionized water to 0.05wt%, and ultrasonically shaken for 60min to make it uniformly dispersed. Put the conductive glass prepared in step (1) vertically into a uniformly dispersed ...

Embodiment 3

[0050] A Highly Stable Visible Light Catalytic Activity SnO 2 The preparation method of PC / CdS photonic crystal structure composite photocatalyst, the method is to prepare SnO on FTO substrate by liquid deposition method 2 Photonic crystals were then sensitized with CdS quantum dots using continuous chemical water bath deposition assisted by sonic digestion to prepare a new type of SnO 2 PC / CdS photonic crystal structure. The method specifically includes the following steps:

[0051] (1) FTO conductive glass with a thickness of 1.1 mm and a surface resistance of 15 Ω / sq was ultrasonically cleaned with acetone, absolute ethanol and pure water in turn, and dried with a hair dryer for use;

[0052] (2) Dilute the 5%wt polystyrene microsphere suspension with a size of 240nm to 0.05wt% with deionized water, and ultrasonically shake for 60min to make it uniformly dispersed. Put the conductive glass prepared in step (1) vertically into a uniformly dispersed polystyrene microsphere suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com