Waterproof slurry with sterilization function for toilet bath room decoration surfaces

A waterproof slurry and bathroom technology, applied in the direction of cement coating, biocide-containing paint, sustainable waste treatment, etc., can solve problems such as cracking construction, efflorescence of facing mortar, difficulties, etc., and achieve extended shelf life and decorative effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 According to the following formula, the water-proof slurry with sterilization function for toilet and bath room facing of the present invention was prepared:

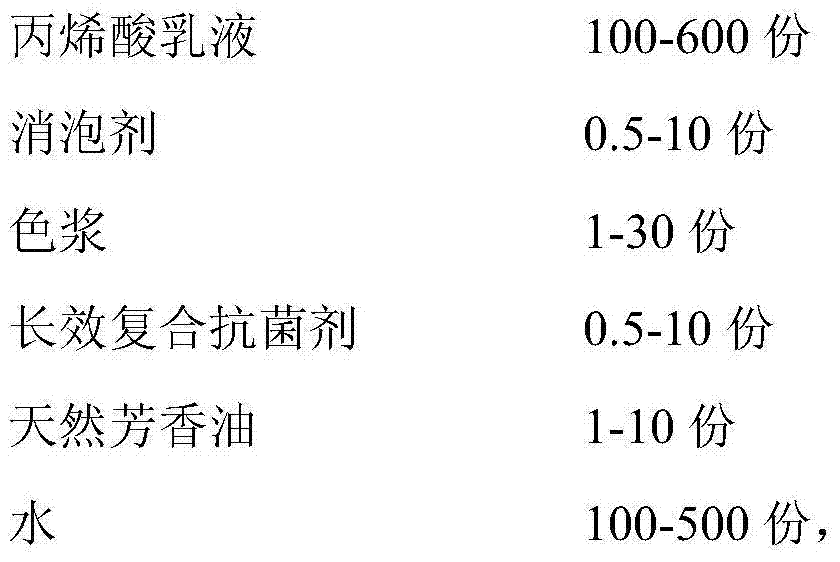

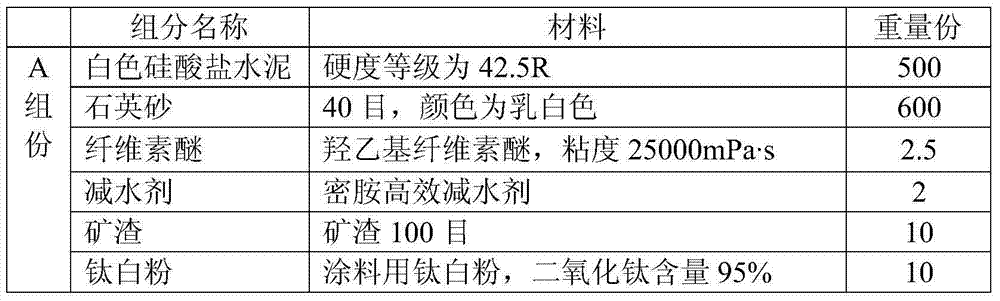

[0049] (1) The formula is shown in the following table:

[0050]

[0051]

[0052] (2) Preparation:

[0053] Accurately weigh each component according to the formula, and manually stir and mix in advance to form a uniform component A system and a component B system. According to the powder-liquid ratio of component A: component B=1:0.3, first put component B into the cement mortar mixer, then add component A, stir at low speed, and stir for 5 minutes until the mixture is uniform.

[0054] The water-proof slurry prepared above that can be used for colored finishes was tested. As shown in the table below, all the indicators meet the JC / T2090-2011 polymer cement waterproof slurry standard.

[0055]

Embodiment 2

[0056] Example 2 According to the following formula, the water-proof slurry with sterilization function for toilet and bath room finishing of the present invention was prepared:

[0057] (1) The formula is shown in the following table:

[0058]

[0059] (2) Preparation: Accurately weigh each component according to the formula, manually stir and mix in advance to form a uniform component A system and a component B system. According to the powder-liquid ratio of component A: component B=1:0.3, first put component B into the cement mortar mixer, then add component A, stir at low speed, and stir for 10 minutes until the mixture is uniform.

Embodiment 3

[0060] Example 3 According to the following formula, the water-proof slurry with sterilization function for toilet and bath room facing of the present invention was prepared:

[0061] (1) The formula is shown in the following table:

[0062]

[0063]

[0064] (2) Preparation: Accurately weigh each component according to the formula, manually stir and mix in advance to form a uniform component A system and a component B system. According to the powder-liquid ratio of component A: component B=1:0.3, first put component B into the cement mortar mixer, then add component A, stir at low speed, and stir for 5 minutes until the mixture is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com