Moldable autogenous bone mud and preparation method thereof

An autologous bone, plastic technology, applied in the direction of prosthesis, medical science, etc., can solve the problem that the volume of bone powder cannot meet the reconstruction of the cavity, the effect of the reconstruction of the surgical area, and increase the risk of secondary surgery, so as to reduce the surface activity of platelets. , the effect of inhibiting platelet aggregation and adhesion, reducing the risk of secondary surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

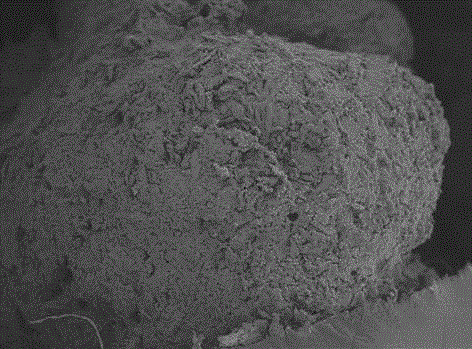

Image

Examples

Embodiment 1

[0042] A moldable autologous bone paste, which includes the following components: autologous bone powder, Panax notoginseng saponins powder, human cryoprecipitate freeze-dried powder, calcium chloride solution;

[0043] In this example, the volume ratio of autologous bone powder, Panax notoginseng saponins powder and human cryoprecipitate freeze-dried powder is 1:1:1;

[0044] In this example, the volume ratio of the calcium chloride solution to the mixture of Panax notoginseng saponins powder and human cryoprecipitate freeze-dried powder is 1:4, and the mass percent concentration of the calcium chloride solution in this example is 5%. The purity of the Panax notoginseng saponins powder of embodiment is 85%. The Panax notoginseng saponins powder used in this example was provided by Nanjing Jingzhu Biotechnology Co., Ltd.

[0045]The above-mentioned preparation method of a moldable autologous bone paste comprises the following steps:

[0046] Step 1. Preparation of human cryo...

Embodiment 2

[0053] A moldable autologous bone paste, which includes the following components: autologous bone powder, Panax notoginseng saponins powder, human cryoprecipitate freeze-dried powder, calcium chloride solution;

[0054] In this example, the volume ratio of autologous bone powder, Panax notoginseng saponins powder and human cryoprecipitate freeze-dried powder is 1.5:2:1.5;

[0055] In this example, the volume ratio of the calcium chloride solution to the mixture of Panax notoginseng saponins powder and human cryoprecipitate freeze-dried powder is 1:3, and the mass percent concentration of the calcium chloride solution in this example is 4%. The purity of the Panax notoginseng saponins powder of embodiment is 80%.

[0056] The above-mentioned preparation method of a moldable autologous bone paste comprises the following steps:

[0057] Step 1. Preparation of human cryoprecipitate freeze-dried powder: vacuum freeze-dry human cryoprecipitate at -55°C for 9 hours to obtain human c...

Embodiment 3

[0064] A moldable autologous bone paste, which includes the following components: autologous bone powder, Panax notoginseng saponins powder, human cryoprecipitate freeze-dried powder, calcium chloride solution;

[0065] In this example, the volume ratio of autologous bone powder, Panax notoginseng saponins powder and human cryoprecipitate freeze-dried powder is 2:1.5:1.5;

[0066] In this example, the volume ratio of the calcium chloride solution to the mixture of Panax notoginseng saponins powder and human cryoprecipitate freeze-dried powder is 1:5, and the mass percentage concentration of the calcium chloride solution in this example is 6%. The purity of the Panax notoginseng saponins powder of embodiment is 90%.

[0067] The above-mentioned preparation method of a moldable autologous bone paste comprises the following steps:

[0068] Step 1. Preparation of human cryoprecipitate freeze-dried powder: vacuum freeze-dry human cryoprecipitate at -57°C for 7 hours to obtain huma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com