Treatment method of feedwater raw water

A treatment method and raw water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of reduced turbidity removal effect of raw water, powerlessness, high ammonia nitrogen, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

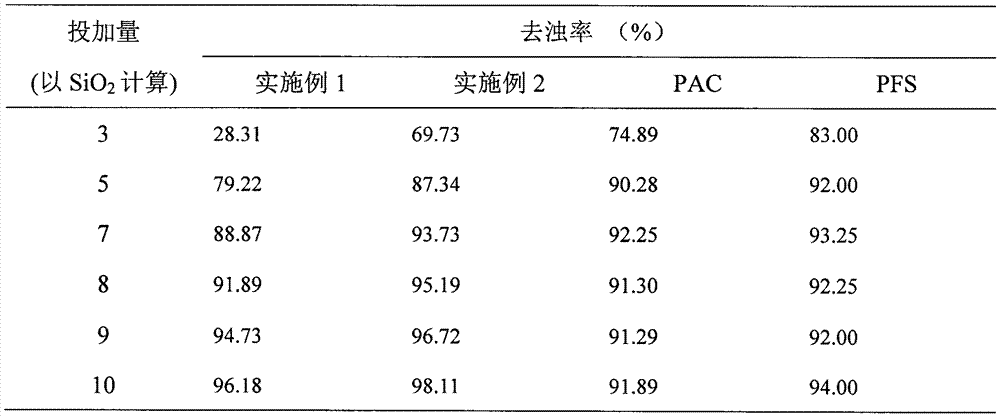

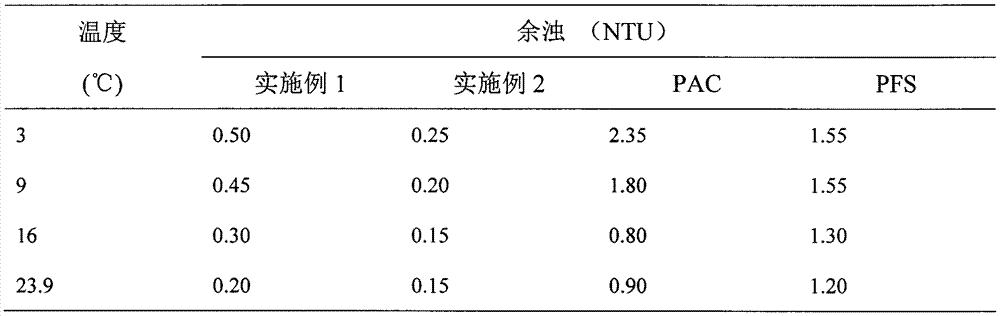

[0011] The modified polysilicate microgel flocculant is prepared by the following method:

[0012] Under high-speed stirring conditions, 200kg of sodium silicate with a silicon dioxide concentration of 2wt% was added to 80ppm of silicon dioxide powder, and vigorously stirred in a drum stirring device to keep the Reynolds number of the liquid during the stirring process at 10000, and then use The dilute sulfuric acid with a concentration of 20wt% by weight is acidified until the pH of the solution is 10, and the instant viscosity of the mixed solution measured by an online viscometer is 20 mPa.

[0013] The raw water is lake water with a turbidity of 10-15NTU, a pH of 7.2, and a water temperature of 14°C. Add raw water into milk of lime, adjust the pH value at 8.5, then add the liquid obtained by mixing sodium silicate and sulfuric acid through a high-speed stirrer, and add sewage at a ratio of 0.05wt%, keep the instant viscosity of the mixed solution less than 50mPa·S, and mai...

Embodiment 2

[0019] The modified polysilicate microgel flocculant is prepared by the following method:

[0020] Under high-speed stirring conditions, 400kg of sodium silicate with a silicon dioxide concentration of 4wt% was added to 150ppm of silicon dioxide powder, and vigorously stirred in a drum stirring device to keep the Reynolds number of the liquid during the stirring process at 12000, and then use The dilute sulfuric acid with a concentration of 20wt% was acidified until the pH of the solution was 9, and the instant viscosity of the mixed solution was measured as 22 mPa.S by an online viscometer at the same time, that is, a polysilicic acid microgel was prepared.

[0021] The raw water is lake water with a turbidity of 10-15NTU and a pH of 7.2. Add raw water into milk of lime, adjust the pH value at 8.5, then add the liquid obtained by mixing sodium silicate and sulfuric acid through a high-speed stirrer, and add sewage at a ratio of 0.05wt%, keep the instant viscosity of the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com