Method for preparing tributyl citrate by taking macroporous strong-acid cation exchange resin as catalyst

A technology of strongly acidic cation, tributyl citrate, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult industrialization, inconvenient operation, high investment cost, and the like, Achieve the effect of being conducive to large-scale industrial production, short reaction time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

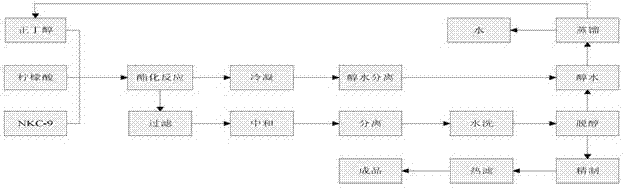

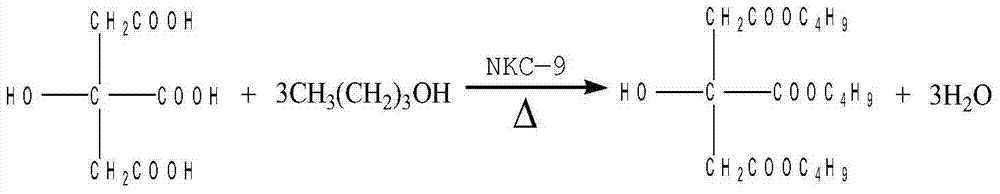

Method used

Image

Examples

Embodiment Construction

[0021] The scheme and effect of the present invention will be further explained below in conjunction with the implementation case.

[0022] Add 126g of citric acid and 247.5mL of n-butanol to a four-necked flask equipped with electric stirring, thermometer, reflux condenser, and water separator. Heat and stir below 70℃. After the citric acid is completely dissolved, add the above-mentioned macroporous strong acid Cation exchange resin (NKC-9) is used as catalyst 18.9g, heated at 108~140℃ under reflux and stirred to separate the water produced by the reaction from the water separator, and then enter the water separator to stop the reaction until there is no water; after the reaction, add it Stirring 5% NaOH aqueous solution to neutralize unreacted citric acid. After the neutralization reaction is completed, wash with hot water at 60~70℃ until it is neutral. The separated organic phase is at a vacuum degree of -0.08~0.1mpa and temperature Distill off water and excess n-butanol unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com