Method for low-cost purification of exenatide

A low-cost exenatide technology, applied in the field of peptide purification, to achieve high yield, cost saving, and environmental protection of the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

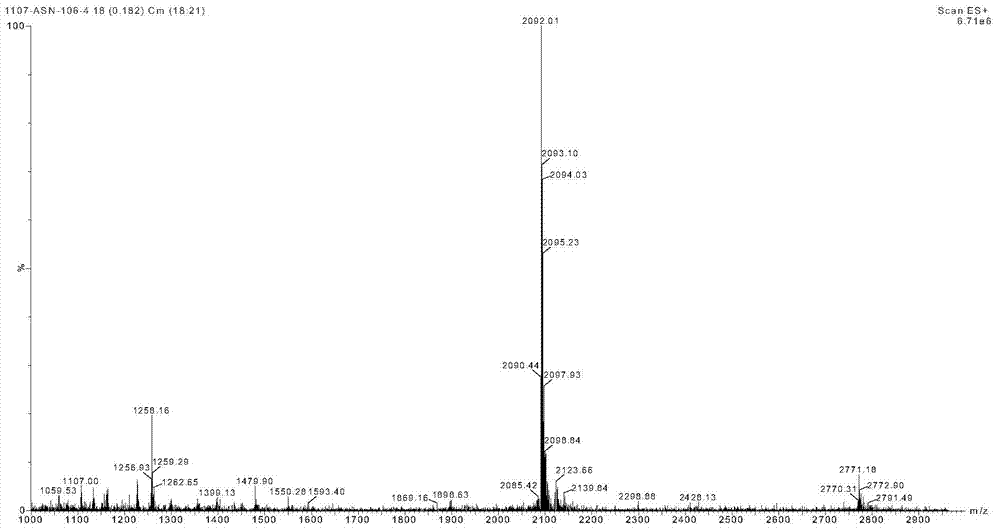

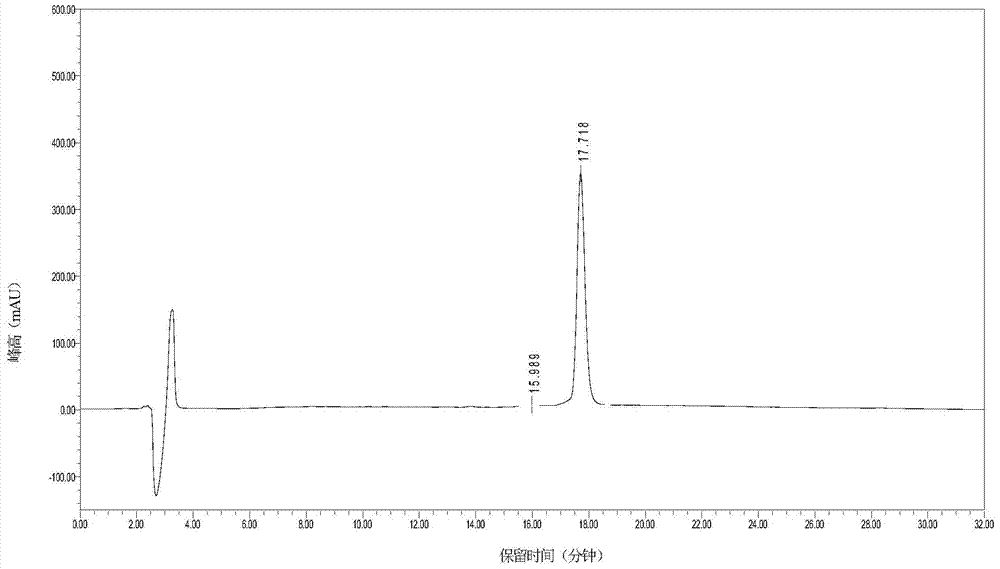

Image

Examples

Embodiment 1

[0027] 1. Sample dissolution

[0028] Dissolve 0.2 g of the crude exenatide obtained by solid-phase synthesis in 5 mL of 20% acetic acid aqueous solution, adjust the pH value to 4.0 with 15% sodium hydroxide aqueous solution, and disperse it ultrasonically. After the solution is completely clarified, Filter through a 0.45 μm membrane filter and collect the filtrate.

[0029] 2. Crude and pure

[0030] The filtrate was crudely purified by ion-exchange high-performance liquid chromatography. The filler was a strong cation-exchange column of SP high-flow rate agarose microspheres (provided by GE Healthcare) with a particle size of 45-165 μm. The column packing volume was 15 mL. Phase A is 0.02mol / L acetic acid-sodium acetate aqueous solution with a pH value of 4.0, mobile phase B is 0.02mol / L acetic acid-sodium acetate aqueous solution with a pH value of 4.0 containing 1mol / L sodium chloride, and the flow rate is 4mL / min , the column temperature is 40°C, and the detection wavel...

Embodiment 2

[0036] 1. Sample dissolution

[0037] Dissolve 1.5 g of the crude exenatide obtained by solid-phase synthesis in 50 mL of 20% acetic acid aqueous solution, adjust the pH value to 4.0 with 15% sodium hydroxide aqueous solution, and disperse ultrasonically until the solution is completely clarified. Filter through a 0.45 μm membrane filter and collect the filtrate.

[0038] 2. Crude and pure

[0039]The filtrate was crudely purified by ion-exchange high-performance liquid chromatography, and the filler was a strong cation exchange column of SP high-flow rate agarose microspheres with a particle size of 50-160 μm (provided by Xi’an Jiaotong University Baosai Biotechnology Co., Ltd.). The filling volume is 150mL, the mobile phase A is 0.02mol / L acetic acid-sodium acetate aqueous solution with a pH value of 4.0, and the mobile phase B is 0.02mol / L acetic acid-sodium acetate with a pH value of 4.0 containing 1mol / L sodium chloride Aqueous solution, the flow rate is 8mL / min, the co...

Embodiment 3

[0045] In the crude purification step 2 of this embodiment, the mobile phase gradient is selected from 0 to 60 minutes A:B from 60:40 to 30:70. The other steps were the same as in Example 2 to obtain exenatide with a purity greater than 98%, and the purification yield was 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com