Method for preparing polyaniline/ferroferric oxide electromagnetic composite material

An electromagnetic composite material and a technology of ferric tetroxide, which is applied in the field of preparation of polyaniline/iron tetroxide electromagnetic composite materials, can solve the problems of complex synthesis method, easy falling off of magnetic particles, complicated synthesis process, etc. The effect of good magnetic properties, good conductivity stability and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

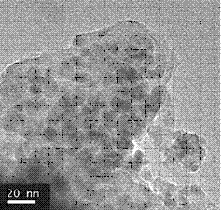

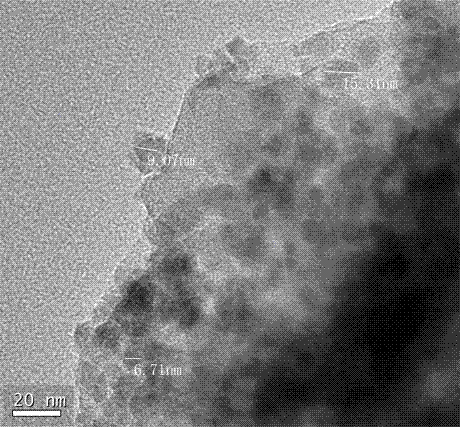

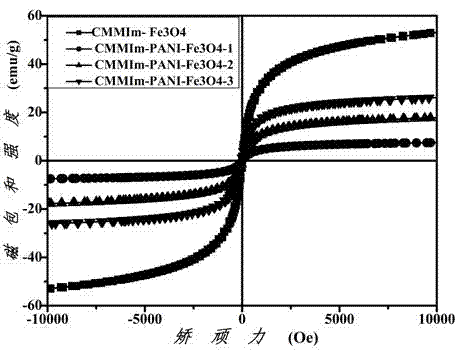

[0013] 10g 1-carboxymethyl-3-methylimidazole hydrochloride ionic liquid, 0.0004mol FeCl 3 ·6H 2 O, 0.0003mol FeCl 2 ·3H 2 Mix O with 20ml of deionized water, stir at 0~40°C until fully dissolved, then heat up to 95°C, add 0.0655mol NaOH until the pH value of the mixed solution is greater than 10, and continue the constant heat reaction for 1h. After the reaction is completed, the solution is ultrasonically 10 min and cooled to room temperature. Dissolve 0.0309mol of sulfamic acid and 0.0220mol of aniline monomer into 30ml of deionized water, add to the above-mentioned mixed solution, stir vigorously for 30min at normal temperature and pressure, then add 10ml of hydrochloric acid solution containing 0.218mol of ammonium persulfate (the concentration of hydrochloric acid is 1mol / l), stirred and reacted for 4 hours; the reaction solution was filtered and washed until the filtrate was neutral; finally, the filter cake was vacuum-dried at 40°C and crushed to obtain a dark green ...

Embodiment 2

[0015] 5g 1-carboxymethyl-3-methylimidazole hydrochloride ionic liquid, 0.0004mol FeCl 3 ·6H 2 O, 0.0003mol FeCl 2 ·3H 2 Mix O with 20ml of deionized water, stir at 0~40°C until fully dissolved, then heat up to 95°C, add 0.0655mol NaOH until the pH value of the mixed solution is greater than 10, and continue the constant heat reaction for 1h. After the reaction is completed, the solution is ultrasonically 10 min and cooled to room temperature. Dissolve 0.0409mol of sulfamic acid and 0.0220mol of aniline monomer into 30ml of deionized water, add to the above mixed solution, stir vigorously at normal temperature and pressure for 30min, then add 10ml of hydrochloric acid solution containing 0.218mol of ammonium persulfate (the concentration of hydrochloric acid is 1mol / l), stirred and reacted for 4 hours; the reaction solution was filtered and washed until the filtrate was neutral; finally, the filter cake was vacuum-dried at 40°C and crushed to obtain a dark green conductive ...

Embodiment 3

[0017] 5g 1-carboxymethyl-3-methylimidazole hydrochloride ionic liquid, 0.0008mol FeCl 3 ·6H 2 O, 0.0006mol FeCl 2 ·3H 2 Mix O with 20ml of deionized water, stir at 0~40°C until fully dissolved, then heat up to 95°C, add 0.0457mol NaOH until the pH value of the mixed solution is greater than 10, continue the constant heat reaction for 1h, and after the reaction is completed, the solution is ultrasonically 10 min and cooled to room temperature. Dissolve 0.0440mol of sulfamic acid and 0.0220mol of aniline monomer into 30ml of deionized water, add to the above mixed solution, stir vigorously for 30min at normal temperature and pressure, then add 10ml of hydrochloric acid solution containing 0.218mol of ammonium persulfate (the concentration of hydrochloric acid is 1mol / l), stirred and reacted for 4 hours; the reaction solution was filtered and washed until the filtrate was neutral; finally, the filter cake was vacuum-dried at 40°C and crushed to obtain a dark green conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com