Tooth desensitizer as well as preparation method and application thereof

A technology for desensitizing agents and teeth, applied in the field of tooth desensitizing agents, can solve problems such as dentin hypersensitivity, prolapse, and mutual fusion, and achieve prevention and treatment of oral diseases, excellent biocompatibility, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Provide silica nanoparticles

[0048] Available in 100nm silica nanoparticles

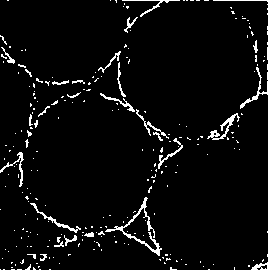

[0049] Such as figure 1 The depth to which such silica nanoparticles can penetrate into dentinal tubules by surface application was characterized by confocal laser, as shown. The arrow shows the smeared side of the material, and a sloping sample boundary can be seen. The red light is excited by the rhodamine B dye encapsulated in the silica particles, which marks the location of the silica spheres, so the depth reached by the red area indicates the depth the material can reach inside the dentinal tubules, the deepest It can reach 160 microns, and the brightest part of the laser, that is, the universal penetration reaches 110 microns.

[0050] (2) Melting of bioactive glass

[0051] Bioactive glass purchased from Shanghai Silicon Health Biomaterials Co., Ltd. was heated to 1400°C to melt it.

[0052] (3) Dip the silica nanoparticles into the molten bioactive glass for 2 minutes, so t...

Embodiment 2

[0063] (1) Preparation of mesoporous silica nanoparticles

[0064] The ratio of raw materials is cetyltrimethylammonium bromide (CTAB): deionized water: sodium hydroxide: tetraethyl orthosilicate (TEOS) = 1: 8504: 2.55: 8.13 (molar ratio); Mix cetyltrimethylammonium bromide, deionized water and sodium hydroxide, stir the reaction system at 70°C until the temperature is stable, and after the cetyltrimethylammonium bromide is completely dissolved, add n- Ethyl silicate; the reaction system was kept at 70°C for 2 hours. After the reaction, the white solid was obtained by suction filtration and dried in an oven at 50°C for 10 hours; the obtained white powder sample was ground with a mortar and put into a crucible , calcined in a muffle furnace at 550°C for 4 hours to remove the template agent CTAB; the calcined sample was ground again to obtain mesoporous silica nanoparticles with ordered pores, the pore volume was 0.84cm3 / g, and the pore diameter was 3.0 nm;

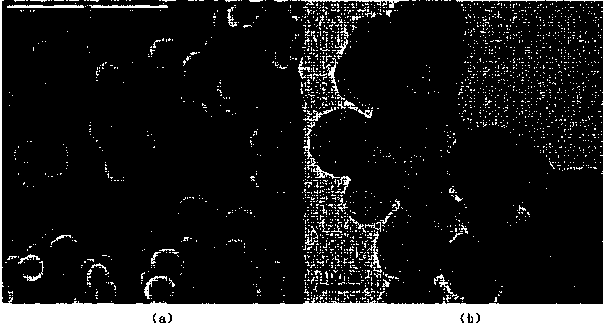

[0065] The scanni...

Embodiment 3

[0074] (1) Preparation of mesoporous silica nanoparticles

[0075] The ratio of raw materials is cetyltrimethylammonium bromide (CTAB): deionized water: sodium hydroxide: tetraethyl orthosilicate (TEOS) = 1: 4859: 2: 8.13 (molar ratio); according to the above formula Mix cetyltrimethylammonium bromide, deionized water and sodium hydroxide, stir the reaction system at 70°C until the temperature is stable, and after the cetyltrimethylammonium bromide is completely dissolved, add n- Ethyl silicate; the reaction system was kept at 70°C for 2 hours. After the reaction, the white solid was obtained by suction filtration and dried in an oven at 50°C for 10 hours; the obtained white powder sample was ground with a mortar and put into a crucible , calcined in a muffle furnace at 550°C for 4 hours to remove the template agent CTAB; the calcined sample was ground again to obtain mesoporous silica nanoparticles with ordered pores, the pore volume was 0.89cm3 / g, and the pore diameter was 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com