Gemini surfactant containing sulfo group and sulfate group anions

A sulfate-based, gemini-surface technology, applied in the preparation of sulfonates, drilling compositions, organic chemistry, etc., can solve the effect of low interfacial tension foaming and stabilizing, cannot meet the needs of practical engineering, and is difficult to achieve ultra-high Low interfacial tension and other problems, to achieve the effect of strong foaming ability, less by-products, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

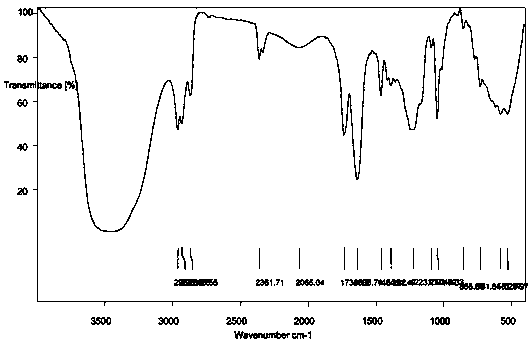

Image

Examples

Embodiment 1

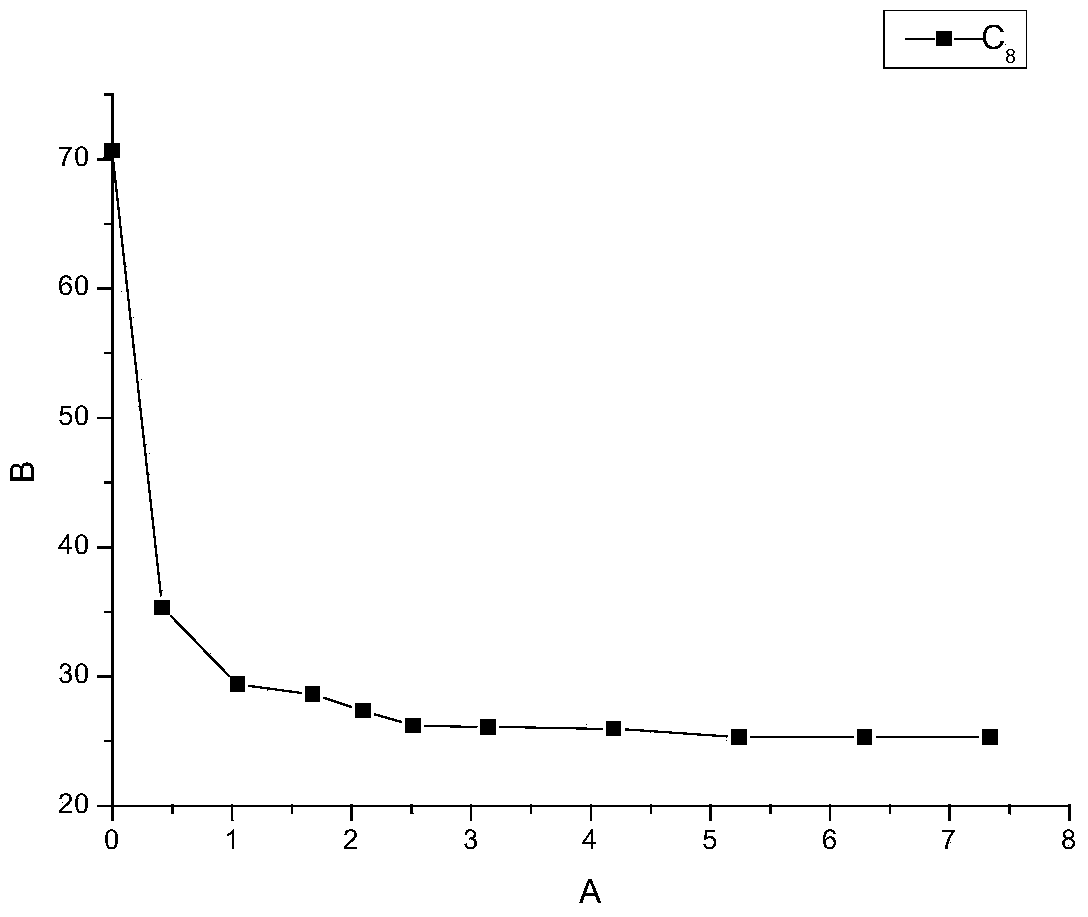

[0038] 3-sulfonic acid-2-sulfate-maleic acid-di-n-octyl disodium (R:C 8 h 17 ) preparation

[0039] (1) Synthesis of maleic acid diester:

[0040] Add 5.64g of maleic anhydride (0.058mol), 16.50g of n-octanol (0.127mol) and toluene solvent (100mL) of concentrated sulfuric acid (5mL) into a 500mL three-necked flask equipped with a stirrer and a reflux condenser, at 130°C After the reaction stopped, wait for the temperature to cool to room temperature, add dropwise saturated sodium bicarbonate solution to the flask to neutralize the excess concentrated sulfuric acid, and adjust its pH=7; wash with saturated NaCl solution, separate the organic phase, and use The solid was dried over sodium sulfate and filtered, and the solvent in the filtrate was evaporated to dryness to obtain 17.21 g of a white solid, with a yield of 87.1%.

[0041] (2) Synthesis of epoxy succinic acid diester:

[0042] Add 17.21g of the product obtained in step (1) (0.051mol), 30% hydrogen peroxide solutio...

Embodiment 2

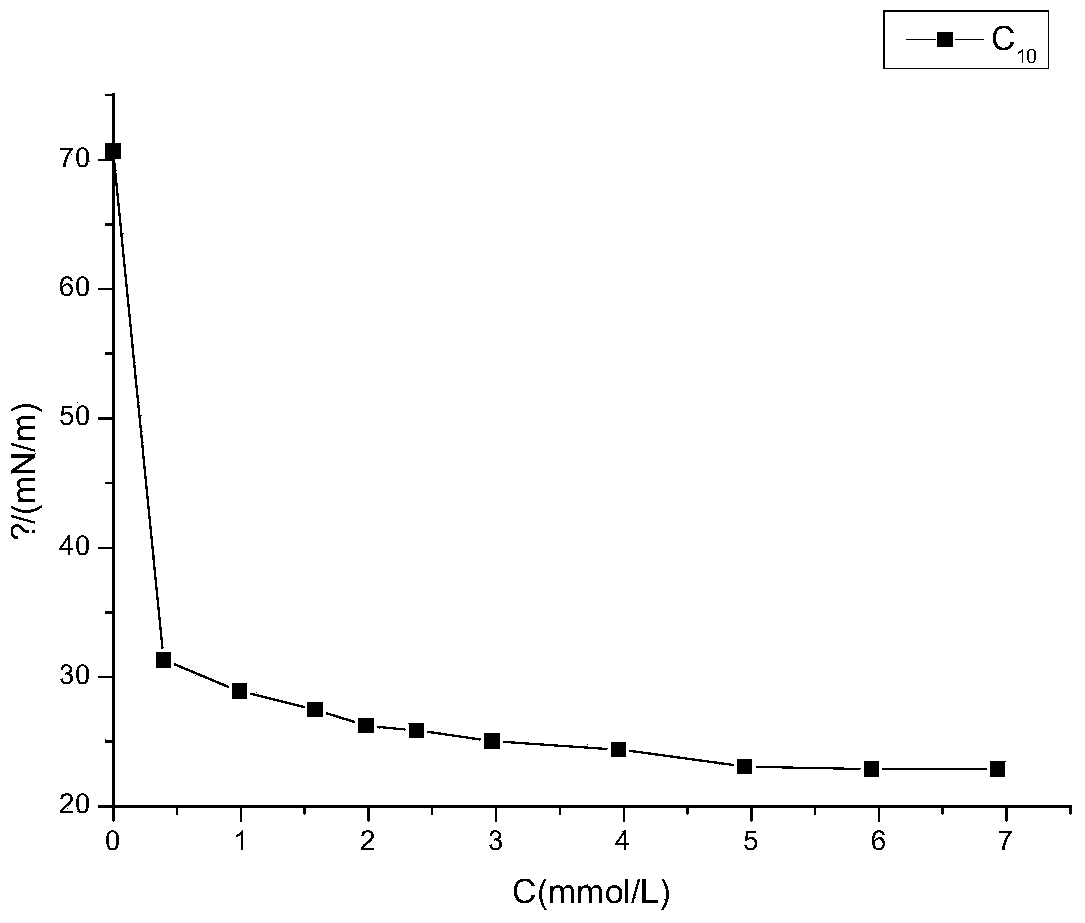

[0048] 3-sulfonic acid-2-sulfate-maleic acid-di-n-decyl disodium (R:C 10 h 21 ) preparation

[0049] (1) Synthesis of maleic acid diester:

[0050] Add 8.57g maleic anhydride (0.087mol), 30.15g n-decyl alcohol (0.19mol) and concentrated sulfuric acid (6mL) in toluene solvent (150mL) into a 500mL three-necked flask equipped with a stirrer and reflux condenser, at 130°C After the reaction stopped, wait for the temperature to cool to room temperature, add dropwise saturated sodium bicarbonate solution to the flask to neutralize the excess concentrated sulfuric acid, and adjust its pH=7; wash with saturated NaCl solution, separate the organic phase, and use The solid was dried over sodium sulfate and filtered, and the solvent in the filtrate was evaporated to dryness to obtain 30.78 g of a white solid, with a yield of 89.2%.

[0051] (2) Synthesis of epoxy succinic acid diester:

[0052] Add 22.34g of the product obtained in step (1) (0.056mol), 30% hydrogen peroxide solution ...

Embodiment 3

[0058] 3-sulfonic acid-2-sulfate-maleic acid-di-n-lauryl disodium (R:C 12 h 25 ) preparation

[0059] (1) Synthesis of maleic acid diester:

[0060] Add 5.64g of maleic anhydride (0.058mol), 23.77g of n-lauryl alcohol (0.128mol) and toluene solvent (100mL) of concentrated sulfuric acid (5mL) into a 500mL three-neck flask equipped with a stirrer and a reflux condenser. After the reaction stopped, wait for the temperature to cool to room temperature, add dropwise saturated sodium bicarbonate solution to the flask to neutralize the excess concentrated sulfuric acid, and adjust its pH=7; wash with saturated NaCl solution, separate the organic phase, and use The solid was dried over sodium sulfate and filtered, and the solvent in the filtrate was evaporated to dryness to obtain 23.01 g of a white solid, with a yield of 87.6%.

[0061] (2) Synthesis of epoxy succinic acid diester:

[0062] Add 23.01g of the product obtained in step (1) (0.051mol), 30% hydrogen peroxide solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com