Method for wet production of phosphoric acid and byproduct, namely white gypsum

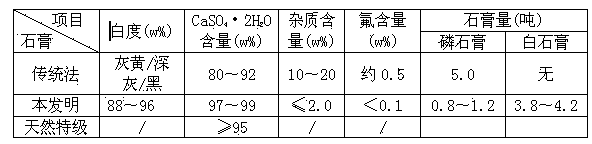

A wet-process phosphoric acid and white gypsum technology, applied in the field of phosphorus chemical industry, can solve the problems of phosphogypsum being discarded or useless in storage, and achieve good environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

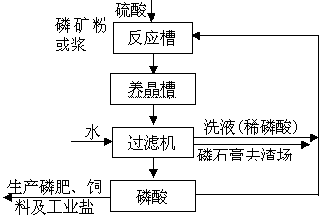

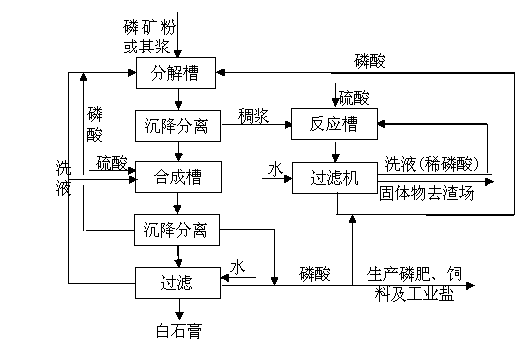

Method used

Image

Examples

example 1

[0030] Example one: (1) 100 parts of phosphoric acid with 100 parts of phosphorus pentoxide content (w%) 28.4 of 7 parts (by mass parts, the same below) and 100 parts of phosphorus pentoxide content (w%) of 30.2 black phosphate rocks, at 55 0 C~60 0C stirred and reacted for 30 minutes; (2) generate phosphoric acid and calcium phosphate salt solution and solid impurity mixed slurry precipitation for 1.5 hours, layer separation to obtain phosphoric acid and calcium phosphate salt mixed solution and thick slurry containing solid impurities; (3 ) under stirring, add 3 parts of sulfuric acid (content 98%) to react with the mixed solution of phosphoric acid and calcium phosphate salt, precipitate and layer, separate and obtain 4.8 parts of phosphoric acid and white gypsum [whiteness value 93.6, content (w%) 98.8].

[0031] (2) Example two: (1) phosphorus pentoxide content (w%) is 23.3 yellow-gray phosphate rock 8 points and 100 parts phosphorus pentoxide content (w%) is 100 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com