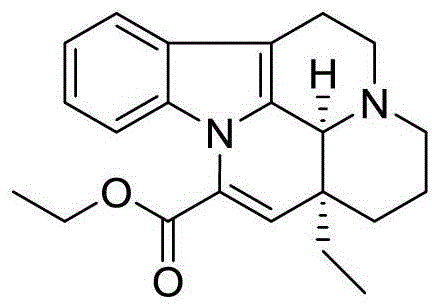

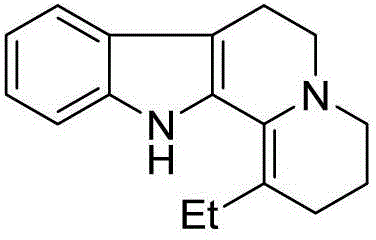

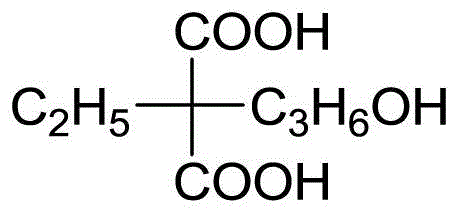

Method for preparing vinpocetine intermediate gamma-hydroxypropyl-ethylmalonic acid

A technology of ethylmalonate and diethyl ethylmalonate, which is applied in the field of preparing and synthesizing vinpocetine intermediate γ-hydroxypropyl-ethylmalonate, can solve complex operation, large amount of ethanol, Increase the process cost and other problems, to achieve the effect of simple experimental operation, simplified operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 500mL of anhydrous tetrahydrofuran into a 2L dry four-necked bottle, mechanically stir and add 68g (1.98mol) of 70% sodium hydride at the same time, the reaction solution is gray and turbid. At 10°C, 282 g (1.5 mol) of diethyl 2-ethylmalonate was slowly added dropwise, and the dropwise addition was completed in 2 hours, followed by mechanical stirring for 1 hour. Then, 234 g (1.5 mol) of 1-bromo-3-chloropropane was slowly added dropwise, and the dropwise addition was completed within 2 hours, followed by stirring for 8 hours. 300 mL of water was added to the solution and stirred for 1 hour. Extracted with ethyl acetate and concentrated under reduced pressure to obtain 394 g of light yellow oily product γ-chloropropyl-ethylmalonate diethyl ester, the yield was 99%, and the content was 95.8%.

[0018] Add 394g of diethyl ethylmalonate to a 2L four-neck flask, add 200mL of ethanol, and then add 600mL of a prepared 25% sodium hydroxide aqueous solution. Raise the temp...

Embodiment 2

[0020] Add 400mL of N,N-dimethylformamide (DMF) into a 2L dry four-necked bottle, mechanically stir and add 56g (1.63mol) of 70% sodium hydride at the same time, the reaction solution is gray and turbid. At 40°C, 282 g (1.5 mol) of diethyl 2-ethylmalonate was slowly added dropwise, and the dropwise addition was completed in 2 hours, followed by mechanical stirring for 1 hour. Then, 281 g (1.8 mol) of 1-bromo-3-chloropropane was slowly added dropwise, and the dropwise addition was completed within 2 hours, followed by stirring for 15 hours. Add 300 mL of water to the solution and stir for 1 h. Extracted with ethyl acetate and concentrated under reduced pressure to obtain 389 g of light yellow oil γ-chloropropyl-ethylmalonate diethyl ester, the yield was 98%, and the content was 95.2% (GC).

[0021] Add 389g of diethyl ethylmalonate to a 2L four-neck flask, add 200mL of ethanol, and then add 600mL of a prepared 25% sodium hydroxide aqueous solution. Raise the temperature and r...

Embodiment 3

[0023] Add 500mL of anhydrous tetrahydrofuran into a 2L dry four-necked bottle, mechanically stir and add 60g (1.75mol) of 70% sodium hydride at the same time, the reaction solution is gray and turbid. At 20°C, 282 g (1.5 mol) of diethyl 2-ethylmalonate was slowly added dropwise, and the dropwise addition was completed in 2 hours, followed by mechanical stirring for 1 hour. Then, 240 g (1.54 mol) of 1-bromo-3-chloropropane was slowly added dropwise, and the dropwise addition was completed within 2 hours, followed by stirring for 12 hours. 300 mL of water was added to the solution and stirred for 1 hour. Extracted with ethyl acetate, concentrated under reduced pressure to obtain 395 g of light yellow oily product γ-chloropropyl-ethylmalonate diethyl ester, the yield was 99%, and the content was 96.5% (GC).

[0024] Add 395g of diethyl ethylmalonate to a 2L four-neck flask, add 200mL of ethanol, and then add 600mL of a prepared 25% sodium hydroxide aqueous solution. Raise the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com