Environmentally-friendly titanium type pigment and process for preparing pigment by adopting grafting bridging method

A titanium-based pigment, an environmentally friendly technology, applied in the field of chemical pigments, can solve the problems of difficult control of product stability, liquid phase agglomeration, complex process, etc., and achieve the effects of strong tinting strength, bright color, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

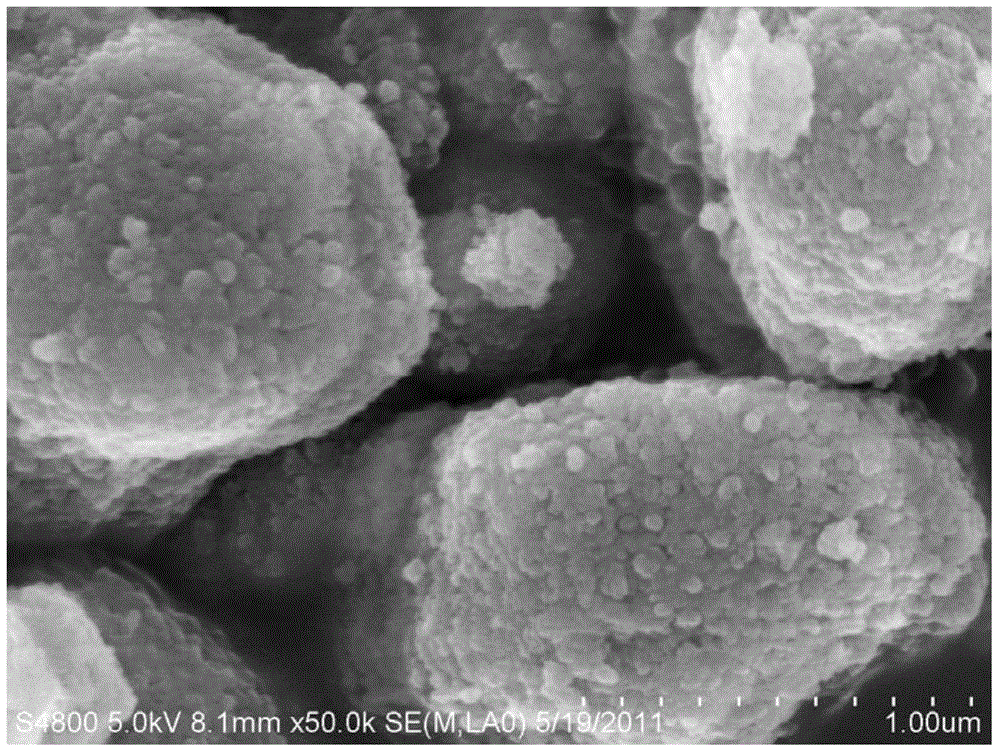

Image

Examples

Embodiment 1

[0053] 1) Add 60g of titanium dioxide and 10g of antimony trioxide into 750ml of water, 20g of nickel nitrate into 200ml of water, and clarify the nickel nitrate solution for later use;

[0054] 2) Weigh 0.3g of the surfactant sodium hexametaphosphate, dissolve it, add it to the mixture of the above titanium dioxide, and disperse it for 0.5h;

[0055] 3) Weigh 4g of sodium hydroxide, 6g of potassium hydroxide, 1g of triethylenetetramine, and 1g of citric acid, dissolve the above four substances in 100ml of water to make a solution, add it to the mixed solution of titanium dioxide, and the temperature of the reaction system rises As high as 50-70°C, control the stirring rate at 400-600r / min, and the processing time is 3h;

[0056] 4) Add nickel nitrate solution slowly, and control the dropping rate to 10ml / min. After all the dropping is completed, adjust the pH value of the reaction system to about 8, and age for 2 hours, so that the nano-nickel hydroxide formed on the surface ...

Embodiment 2

[0060] 1) Add 80g of titanium dioxide and 15g of antimony trioxide into 1000ml of water, 15g of nickel nitrate into 150ml of water, and clarify the nickel nitrate solution for later use;

[0061] 2) Weigh 0.4g of the surfactant sodium hexametaphosphate, dissolve it, add it to the above titanium dioxide mixture, and disperse it for 0.5h;

[0062] 3) Weigh 5g of sodium hydroxide, 10g of potassium hydroxide, 0.5g of triethylenetetramine, and 0.5g of citric acid, dissolve the above four substances in 100ml of water to make a solution, add it to the mixed solution of titanium dioxide, and the reaction system The temperature is raised to 50-70°C, the stirring rate is controlled at 400-600r / min, and the processing time is 3h;

[0063] 4) Add nickel nitrate solution slowly, and control the dropping rate to 10ml / min. After all the dropping is completed, adjust the pH value of the reaction system to about 9, and age for 2 hours, so that the nano-nickel hydroxide formed on the surface of...

Embodiment 3

[0067] 1) Add 75g of titanium dioxide and 12g of antimony trioxide into 870ml of water, 25g of chromium nitrate into 250ml of water, and clarify the chromium nitrate solution for later use;

[0068] 2) Weigh 0.35g sodium hexametaphosphate solution, add it into the titanium dioxide mixture, and disperse it for 0.5h;

[0069] 3) Weigh 5g of sodium hydroxide, 10g of potassium hydroxide, 1.5g of triethylenetetramine, and 1.5g of citric acid, dissolve the above four substances in 100ml of water to make a solution, add it to the mixed solution of titanium dioxide, and the reaction system The temperature is raised to 50-70°C, the stirring rate is controlled at 400-600r / min, and the processing time is 2h;

[0070] 4) Slowly drop in the chromium nitrate solution, and control the dropping rate to 10ml / min. After all the dropping is completed, adjust the pH value of the reaction system to about 10, and age for 2 hours, so that the nano-chromium hydroxide formed on the surface of titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com