Chitosan single guanidine hydrochloride loaded nanometer titanium dioxide compound and preparation method thereof

A technology of nano-titanium dioxide and chitosan, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of limited application of pH sensitivity and low antibacterial activity of chitosan, and achieve high continuous antibacterial effect, excellent anti-ultraviolet radiation, The effect of high-efficiency broad-spectrum antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

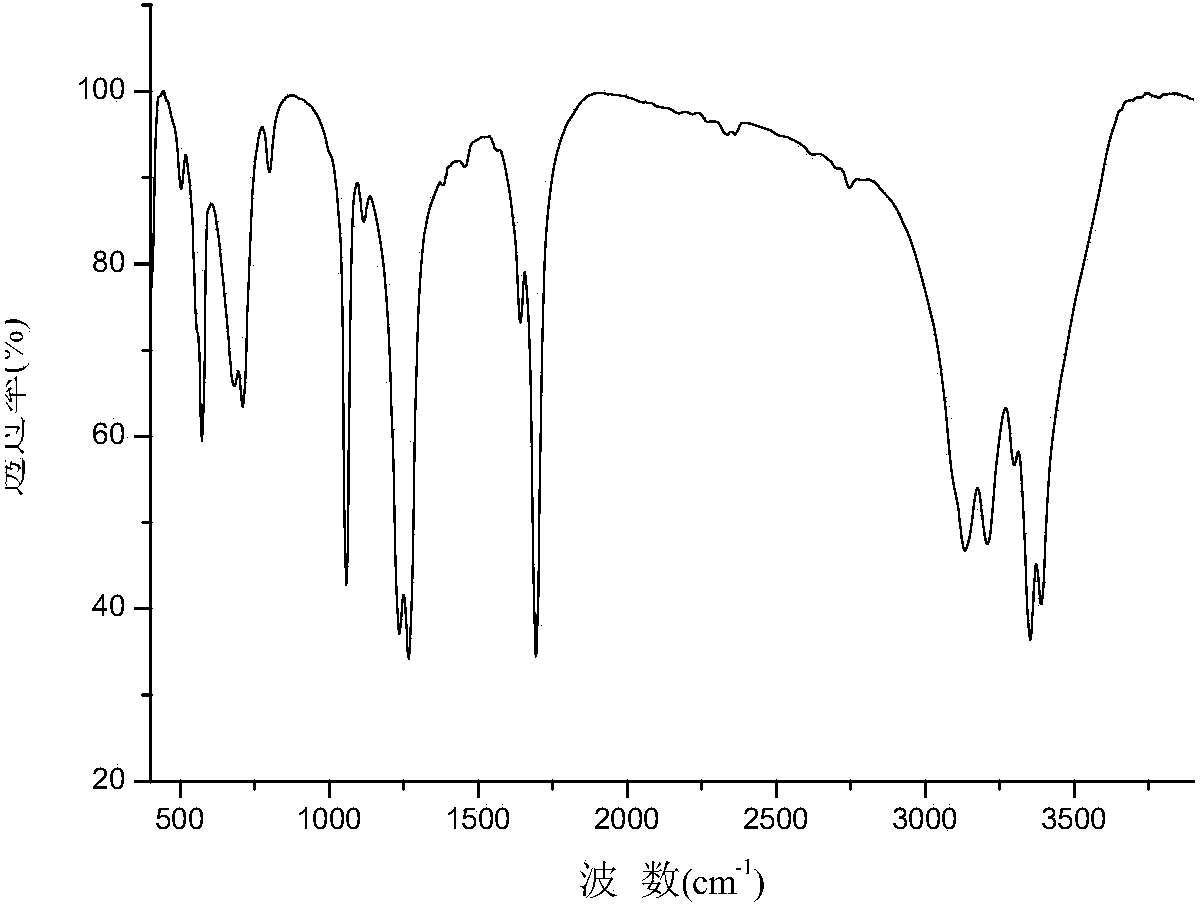

[0025] Take 8mL of hydrogen peroxide in a beaker, add 0.4mL of concentrated sulfuric acid, stir, and make a hydrogen peroxide acidic solution, then weigh 5g of thiourea dioxide, and alternately put the hydrogen peroxide acidic solution and thiourea dioxide into the Erlenmeyer flask, and control the reaction temperature at 50-55°C. After stirring for 2 hours, filter to obtain smooth and shiny thiourea trioxide hydrate crystals; figure 1 is the FT-IR map of thiourea trioxide, where 1230 and 1050cm - The strong absorption peak at , evidenced the formation of thiourea trioxide.

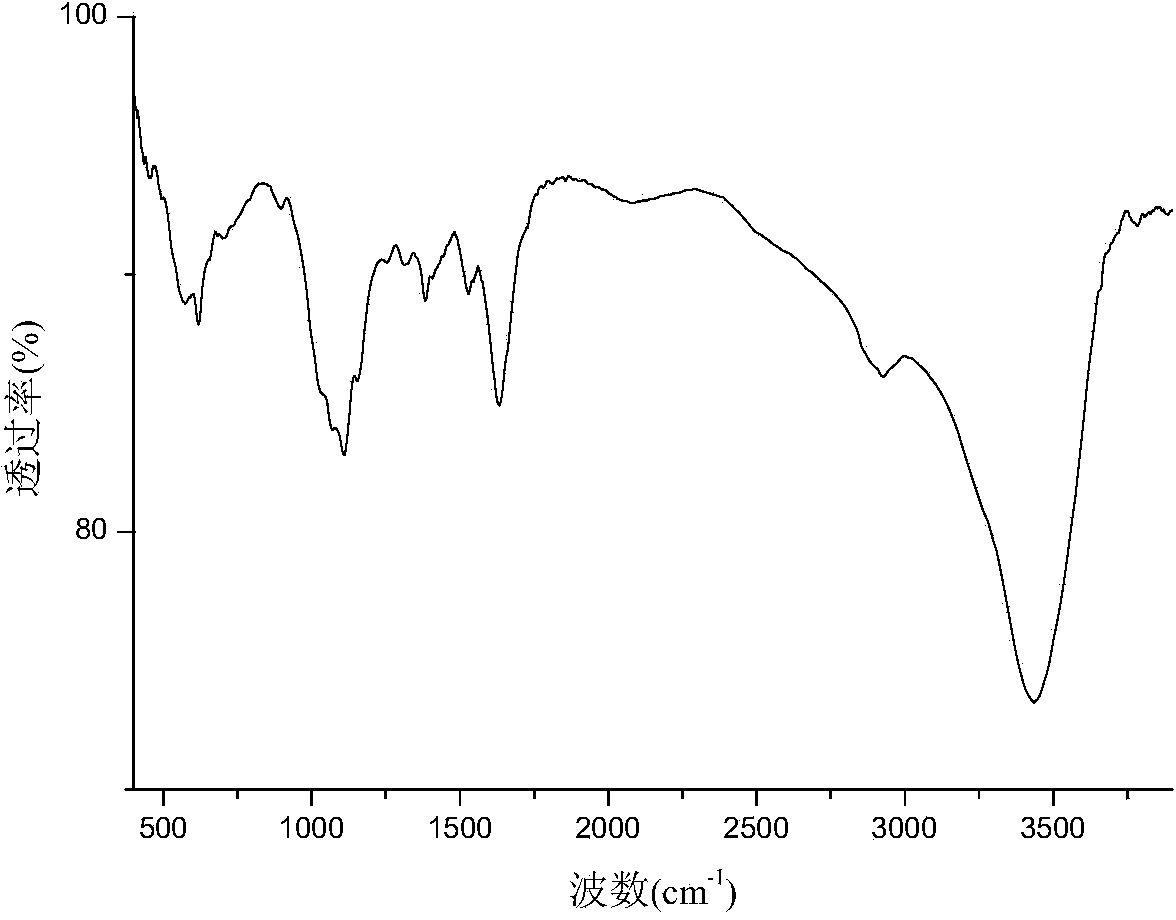

[0026] Weigh 5g of chitosan, add 200mL of hydrochloric acid solution with a concentration of 0.2mol / L, stir thoroughly for 4h; use 50g / L of sodium carbonate solution to adjust the pH of the chitosan solution to 8-9, then wash with distilled water to pH When the value is 7.0 to 7.5, centrifuge, drain part of the upper layer of clear water, put it into a three-hole flask, and start heating to 50°C; add 3.8...

Embodiment 2

[0029] The preparation of chitosan monoguanidine hydrochloride is the same as in Example 1.

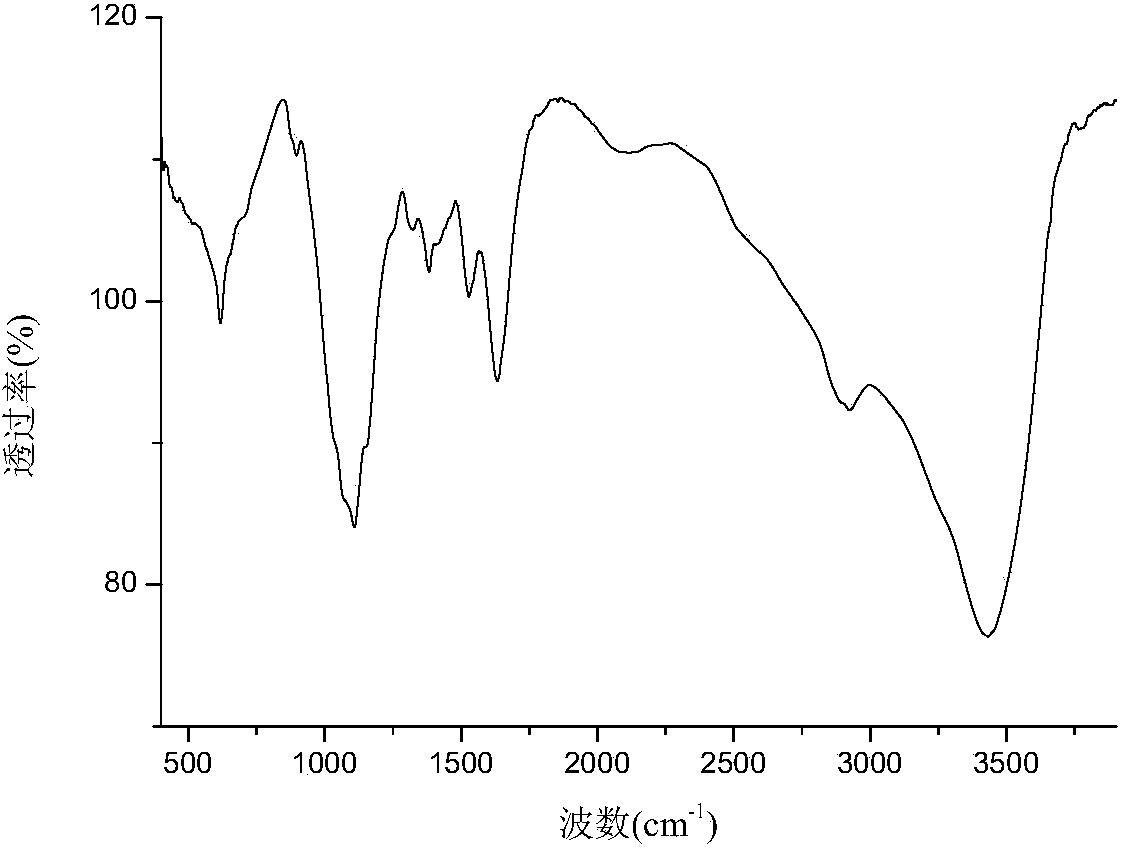

[0030] Take a certain amount of chitosan monoguanidine hydrochloride and dissolve it in water, stir and dissolve, and prepare a chitosan monoguanidine hydrochloride solution with a mass percentage of 5%, take 15mL of the above-mentioned chitosan monoguanidine hydrochloride solution and 0.145g nano-TiO 2Place in a beaker, ultrasonically disperse for 1 hour, then add 0.15mL Tween80 to obtain a pre-emulsified aqueous phase mixture; add 100mL petroleum ether, 50mL liquid paraffin and 7.5mL Span8080 to a three-necked flask, and stir evenly to obtain an oil phase mixture. Add the pre-emulsified water phase mixture to the oil phase mixture by spraying within 30min, control the reaction temperature at 30°C, stir for 0.5h, add 0.75mL glutaraldehyde, continue stirring for 4h, let stand, filter with suction, wash, sample Vacuum drying for 12 hours to obtain chitosan monoguanidine hydrochloride ...

Embodiment 3

[0032] The preparation of chitosan monoguanidine hydrochloride is the same as in Example 1.

[0033] Take a certain amount of chitosan monoguanidine hydrochloride and dissolve it in water, stir and dissolve, and prepare a chitosan monoguanidine hydrochloride solution with a mass percentage of 5%, take 15mL of the above-mentioned chitosan monoguanidine hydrochloride solution and 0.072g nano-TiO 2 Place in a beaker, ultrasonically disperse for 1 hour, then add 0.15mL Tween80 to obtain a pre-emulsified aqueous phase mixture; add 100mL petroleum ether, 50mL liquid paraffin and 7.5mL Span80 to a three-necked flask, and stir mechanically to obtain an oil phase mixture. Add the pre-emulsified water phase mixture to the oil phase mixture by spraying within 30min, control the reaction temperature at 30°C, stir for 0.5h, add 0.75mL glutaraldehyde, continue stirring for 4h, let stand, filter with suction, wash, sample Vacuum drying for 12 hours to obtain chitosan monoguanidine hydrochlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com