Coating-modified anode material of lithium ion battery

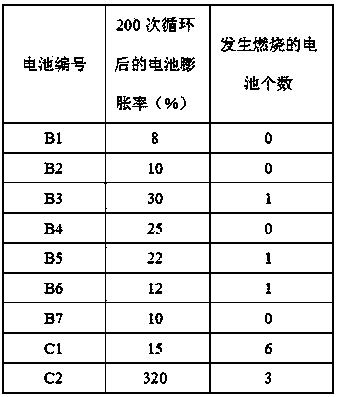

A technology for lithium ion batteries and anode materials, which is applied in the field of coating modified lithium ion battery anode materials, can solve the problems of thermal runaway and combustion of batteries that cannot be well solved, metal oxides do not have good mechanical properties, and batteries Unable to pass the safety test and other problems to achieve the effect of solving the problem of thermal runaway, inhibiting volume expansion and low flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The coated and modified lithium-ion battery anode material provided in this embodiment includes a core layer and a shell layer coated outside the core layer, wherein the core layer is natural graphite, and the shell layer is melamine formaldehyde resin with a decomposition temperature greater than 180°C. And the mass of the shell accounts for 5% of the total mass of the anode material.

[0030] Its preparation method comprises the following steps:

[0031] In the first step, natural graphite is placed in a high mixer and stirred at a speed of 300r / min;

[0032] In the second step, the melamine formaldehyde resin is dispersed in ethanol to form an emulsion, and then the emulsion is added to the sprayer, so that the emulsion is sprayed to the natural graphite in the form of 1 μm droplets. After the spraying is completed, continue to use Stir at 300r / min for 1h, bake at 100°C for 4h to obtain the anode material.

Embodiment 2

[0034] The coated and modified lithium ion battery anode material provided in this embodiment includes a core layer and a shell layer coated outside the core layer, wherein the core layer is artificial graphite, and the shell layer is a phenolic resin with a decomposition temperature greater than 180 ° C, and The mass of the shell accounts for 3% of the total mass of the anode material.

[0035] Its preparation method comprises the following steps:

[0036] In the first step, the artificial graphite is placed in a high mixer and stirred at a speed of 200r / min;

[0037] The second step is to disperse the phenolic resin in acetone to form a solution, and then add the solution to the sprayer, so that the solution is sprayed on the artificial graphite in the form of 2 μm droplets. After the spraying is completed, continue to stir at a speed of 200r / min for 2h , baked at 110°C for 3h to obtain the anode material.

Embodiment 3

[0039] The coated and modified lithium-ion battery anode material provided in this embodiment includes a core layer and a shell layer coated outside the core layer, wherein the core layer is silicon dioxide, and the shell layer is a phenolic resin whose decomposition temperature is greater than 180°C. And the mass of the shell accounts for 10% of the total mass of the anode material.

[0040] Its preparation method comprises the following steps:

[0041] In the first step, silicon dioxide is placed in a high mixer and stirred at a speed of 400r / min;

[0042] The second step is to disperse the phenolic resin in ethanol to form a solution, and then add the solution to the sprayer, so that the solution is sprayed on the artificial graphite in the form of 2.5 μm droplets. After the spraying is completed, continue to stir at a speed of 400r / min 1.5h, baked at 80°C for 5h to obtain the anode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com