Ethynylation catalyst for synthesizing 1, 4-butynediol

A technology of butynediol and catalyst, applied in the field of acetylenic catalyst, can solve the problems of high production cost of 1,4-butynediol, short service life of catalyst, high price of catalyst, etc., and achieves remarkable economic and technical performance, The effect of strong stability and a wide range of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

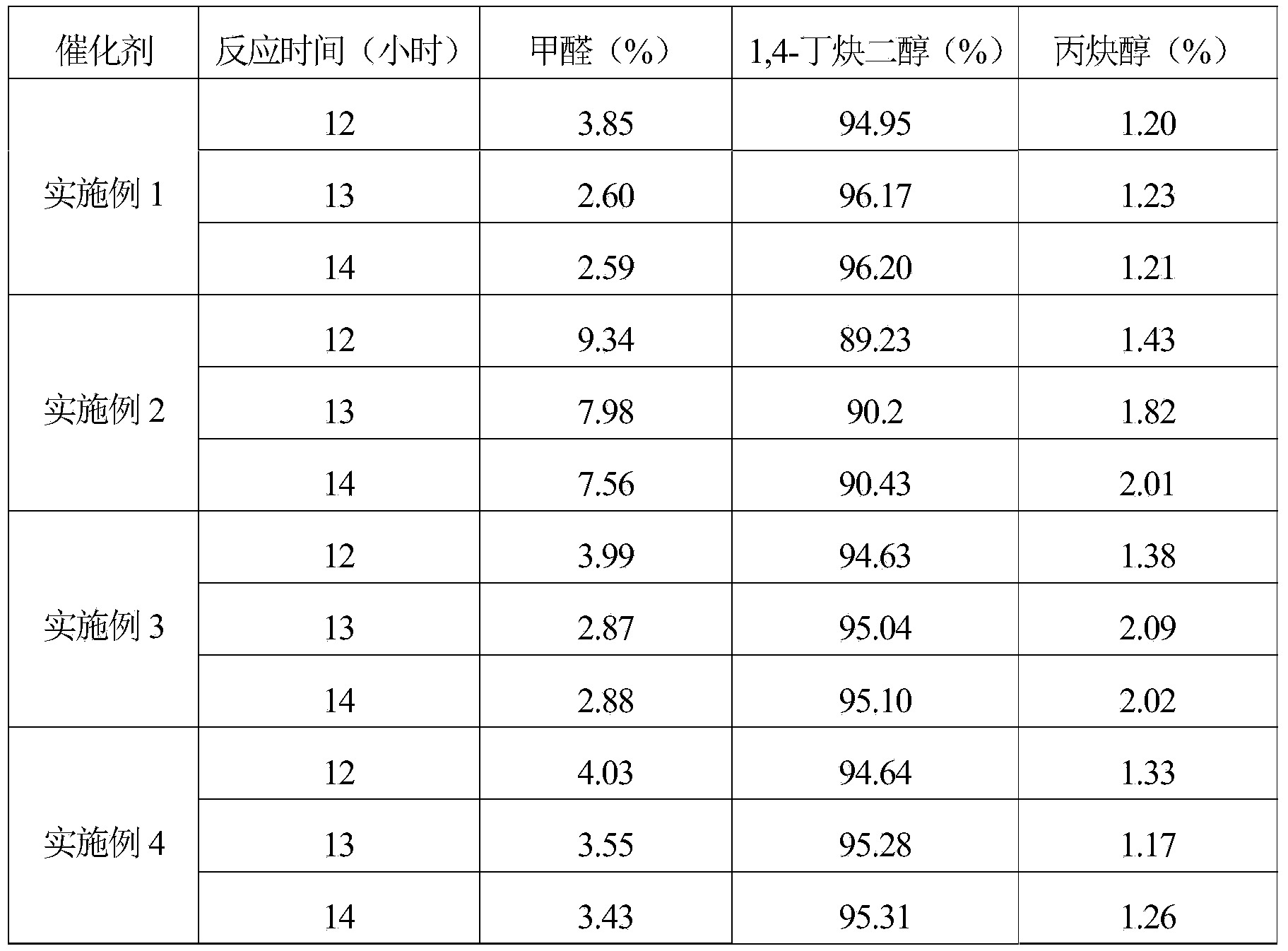

Examples

Embodiment 1

[0016] Disperse 260g of silica sol evenly in 2L of distilled water to obtain an aqueous solution of silica sol; dissolve 500g of copper nitrate, 23g of bismuth nitrate and 160g of magnesium nitrate in 500mL of 10% nitric acid aqueous solution, and slowly add silicon dropwise under stirring. In the sol aqueous solution, the molar ratio of Si atoms to Cu atoms, Bi atoms, and Mg atoms is 1:0.98:0.022:0.3, and a 30% sodium carbonate aqueous solution is added to make the pH of the resulting suspension 6.5 ~ 7.0, continue to stir for 1 hour, let stand for 12 hours, the precipitated precipitate is filtered, washed with distilled water, and dried at 150°C, then placed in a muffle furnace at 500°C for 6 hours to prepare it for synthesis of 1,4- The catalyst for acetylation of butynediol. The particle size distribution of the obtained catalyst is obtained by physical sieving and weighing method: 9% of particles smaller than or equal to 0.710μm, 80% of particles smaller than or equal to 0....

Embodiment 2

[0018] Weigh 1000g of sodium silicate and dissolve it in 10L of water to obtain an aqueous solution of sodium silicate; dissolve 540g of copper chloride, 49g of bismuth nitrate, and 150g of magnesium nitrate in 1L of nitric acid with a mass fraction of 10%. The resulting mixture is stirred under stirring conditions. Drop into the sodium silicate aqueous solution, where the molar ratio of Si atoms to Cu atoms, Bi atoms, and Mg atoms is 1:0.90:0.048:0.28, and neutralize to the pH value with a 23% sodium hydroxide aqueous solution. 6.5 ~ 7.0, continue to stir for 1 hour, let stand for 12 hours, the precipitated precipitate is filtered, washed with distilled water, dried at 150°C, and then placed in a muffle furnace at 460°C for 6 hours to prepare it for synthesis of 1,4- Catalyst for acetylation of butynediol.

Embodiment 3

[0020] Weigh 1220g of sodium silicate and dissolve it in 15L of water to obtain an aqueous solution of sodium silicate; dissolve 180g of magnesium nitrate, 50g of bismuth nitrate, and 900g of copper nitrate in 1L of 10% aqueous nitric acid solution. The resulting mixture is slowly stirred under stirring conditions. Drop into the sodium silicate aqueous solution, where the molar ratio of Si atoms to Cu atoms, Bi atoms, and Mg atoms is 1:0.86:0.024:0.16, and then neutralize to pH value with 30% sodium carbonate in water 6.5 ~ 7.0, after stirring for 1 hour, let stand for 12 hours, the precipitated precipitate is filtered, washed with distilled water, dried at 150°C, and calcined in a muffle furnace at 350°C for 6 hours to prepare it for synthesis 1,4 -Butynediol acetylation catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com