Biomass charcoal, compost containing biomass charcoal, and preparation method of biomass charcoal

A biochar and composting technology, applied in the field of organic fertilizers, can solve the problems of increasing compost ash content, lack of nitrogen protection measures, limited nitrogen protection capacity, etc., to promote fermentation and maturity, good economic and social benefits, and improve application effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of apple branch biochar

[0030] Crush the apple branches to a length of 3-5cm, and heat the apple branches in a cracking furnace under a nitrogen atmosphere. The temperature of the heat treatment is 550°C, and the heat treatment time is 2.5 hours; Mesh sieve to obtain apple branch biochar.

Embodiment 2

[0031] Embodiment 2: Using biochar to prepare compost

[0032] Cow dung, fungus chaff, chicken manure, etc. are used as raw materials, mixed according to 33.3%: 33.3%: 33.3% (mass ratio), and then biochar is added in a proportion of 5% (accounting for the mass ratio of the above mixed material). Adjust the moisture content to 60% of the whole material, stir well, and carry out aeration fermentation composting test in the fermenter (100L), the ventilation rate is 0.6-0.8m 3 ·(kg·d) -1 (calculated as organic matter). The temperature change and nitrogen conversion in the fermentation process were monitored, and the treatment without adding biomass carbon was used as a control. The whole experiment was repeated 3 times.

Embodiment 3

[0033] Embodiment 3: Determination of physical and chemical indicators of compost

[0034] At the beginning of material fermentation, sampling was carried out every 3 days, and the upper, middle and lower layers of the compost were collected at each sampling point for mixing (as one sample). The samples were air-dried and crushed through a 1mm sieve for later use. Determine the total nitrogen and nitrogen composition of the sample and other indicators.

[0035] The following are the test results:

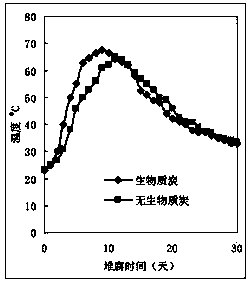

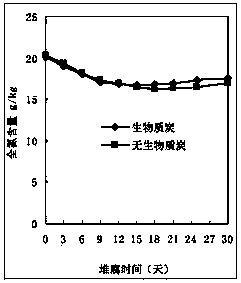

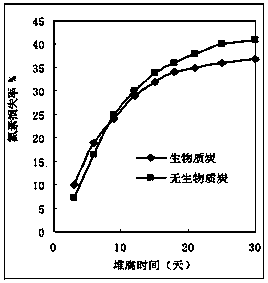

[0036] From figure 1 It can be seen that the addition of biochar increases the fermentation temperature: as can be seen from the figure, the temperature change in the composting process has gone through three stages, namely, the heating stage, the high temperature stage, and the cooling stage. The treatment of adding biochar entered the high-temperature composting stage (>50°C) on the 4th day, reached the highest temperature (67.6°C) on the 9th day, and maintained the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com