Anionic rare earth complex and hydrotalcite composite luminescent ultra slim membrane and preparation method thereof

A rare earth complex and anionic technology, applied in the field of rare earth complex [RE3bath] and hydrotalcite composite luminescent ultra-thin film and its preparation, to achieve the effect of reducing fluorescence quenching and luminescence red shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

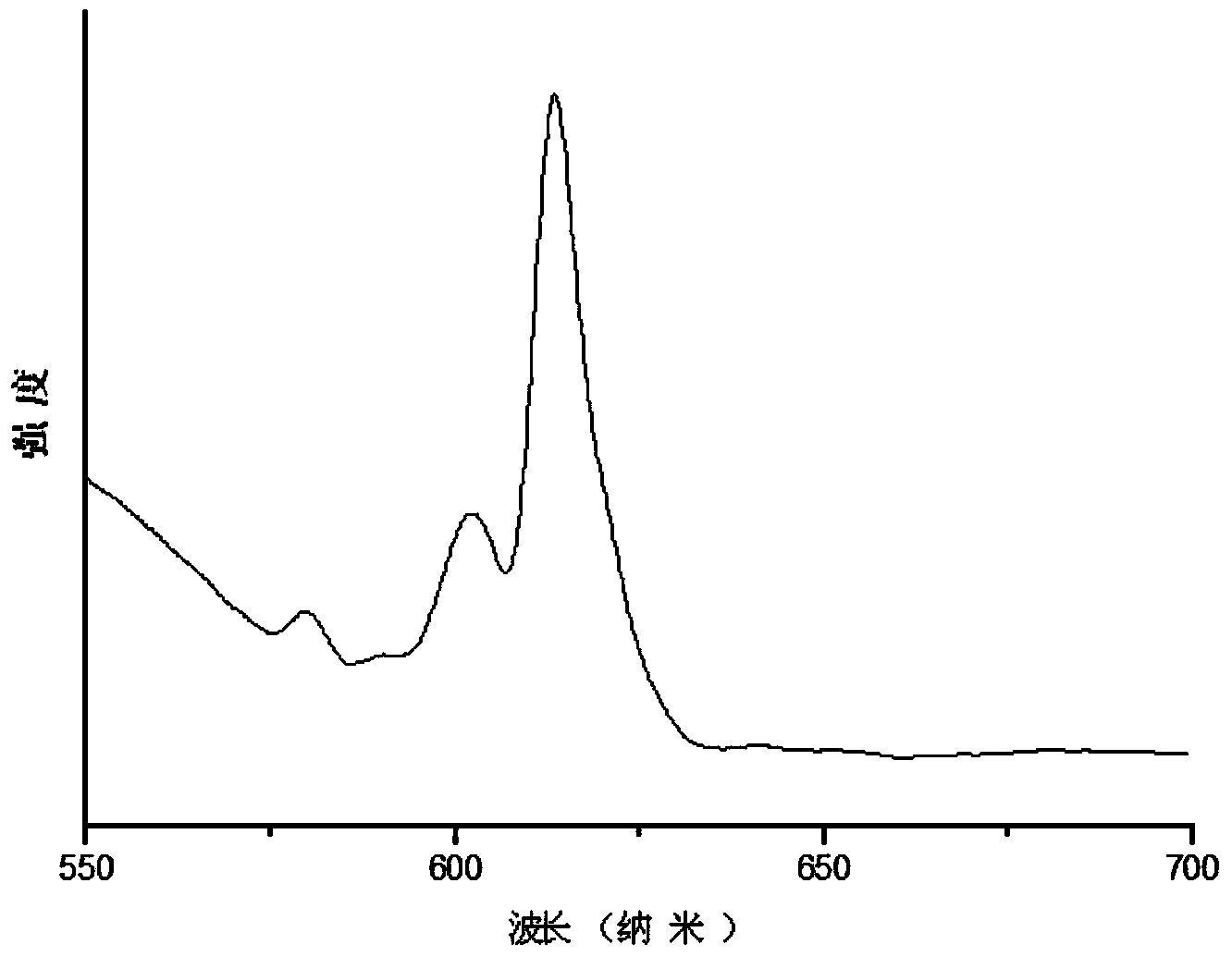

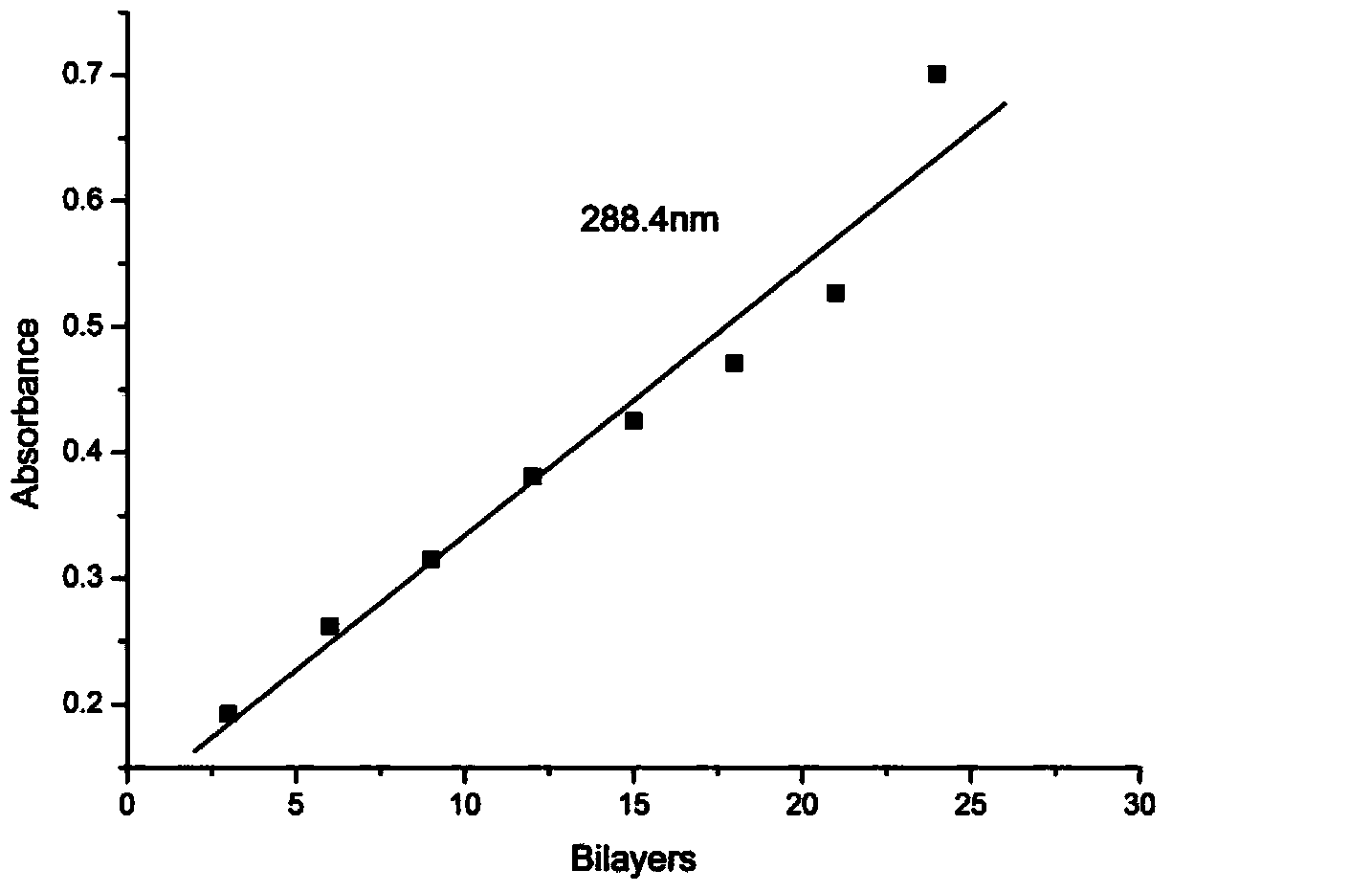

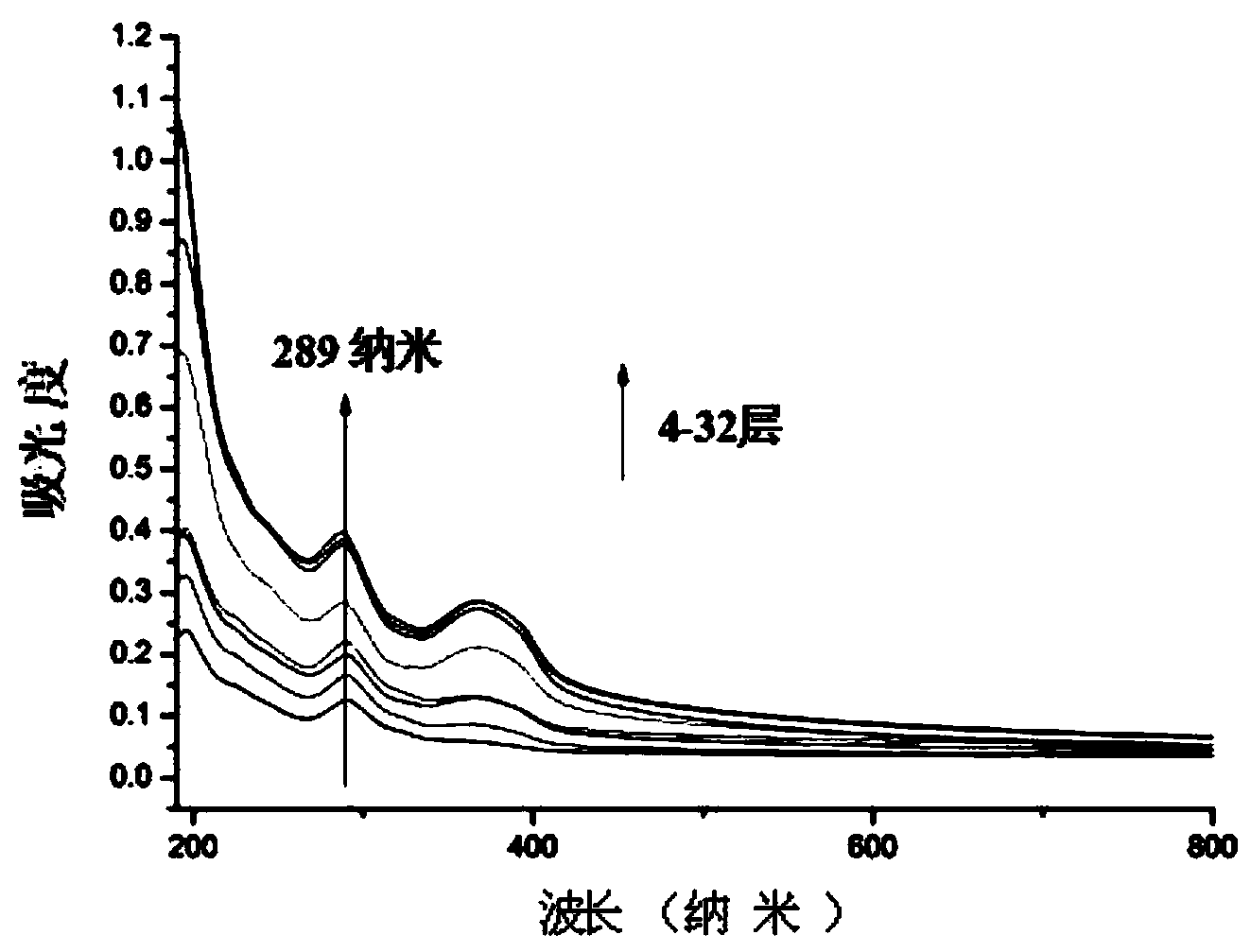

Embodiment 1

[0031] 1. Anionic rare earth complexes [Eu(DBM) 3 bath] preparation:

[0032]Weigh 1mmol of europium chloride, 3mmol of the first ligand dibenzoylmethane (DBM), 1mmol of the second ligand hydrated sodium phenanthroline disulfonate (bath), and dissolve these three substances in 10mL deionized water, 20 mL of absolute ethanol, and 10 mL of deionized water. After adding the first ligand to the rare earth chloride solution, add NaOH solution dropwise to adjust the pH to 6-7, and finally add the second ligand under constant stirring in a water bath at 60°C, a light yellow precipitate will form, continue After stirring for 60 min, it was cooled to room temperature. Transfer to a centrifuge tube, centrifuge at 9000r / min for 5min, remove the liquid part, wash with deionized water, and centrifuge again. Repeat this process three times. The obtained solid part was dried at a temperature of 65° C. for use.

[0033] 2. Preparation of nitrate hydrotalcite precursor by ion exchange met...

Embodiment 2

[0042] 1. Anionic rare earth complex [Tb(DBM) 3 bath] preparation:

[0043] Weigh 1 mmol of terbium chloride, 3 mmol of the first ligand dibenzoylmethane (DBM), and 1 mmol of the second ligand hydrated bathophenanthroline disulfonate (bath), and dissolve these three substances in 10 mL of deionized water, 20 mL of absolute ethanol, and 10 mL of deionized water. After adding the first ligand to the rare earth chloride solution, add NaOH solution dropwise to adjust the pH to 6-7, and finally add the second ligand under constant stirring in a water bath at 78°C, a white precipitate will form, continue stirring After 120 min, cool to room temperature. Transfer to a centrifuge tube, centrifuge at 9000r / min for 5min, remove the liquid part, wash with deionized water, and centrifuge again. Repeat this process three times. The obtained solid was dried at a temperature of 65° C. for use.

[0044] 2. Preparation of nitrate hydrotalcite precursor by ion exchange method:

[0045] a....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com