Method for detecting trace formaldehyde

A detection method and formaldehyde technology, applied in the field of analytical chemistry, can solve the problems of not conforming to the concept of green environmental protection detection, consumption of toxic organic solvents, complex and harsh operating conditions, etc., and achieve good application prospects, simple sample pretreatment, and wide linear range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

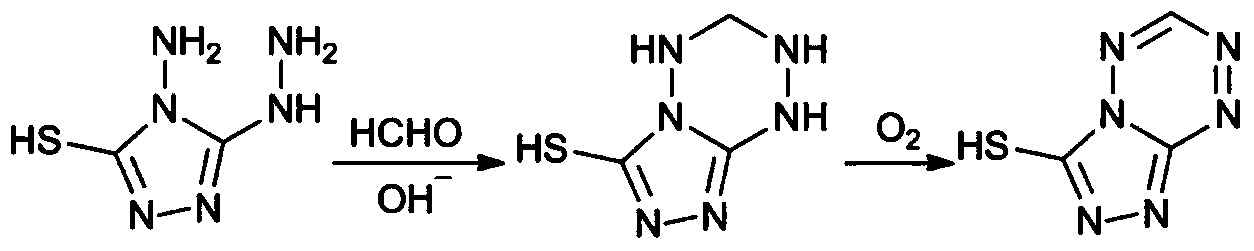

Method used

Image

Examples

Embodiment 1

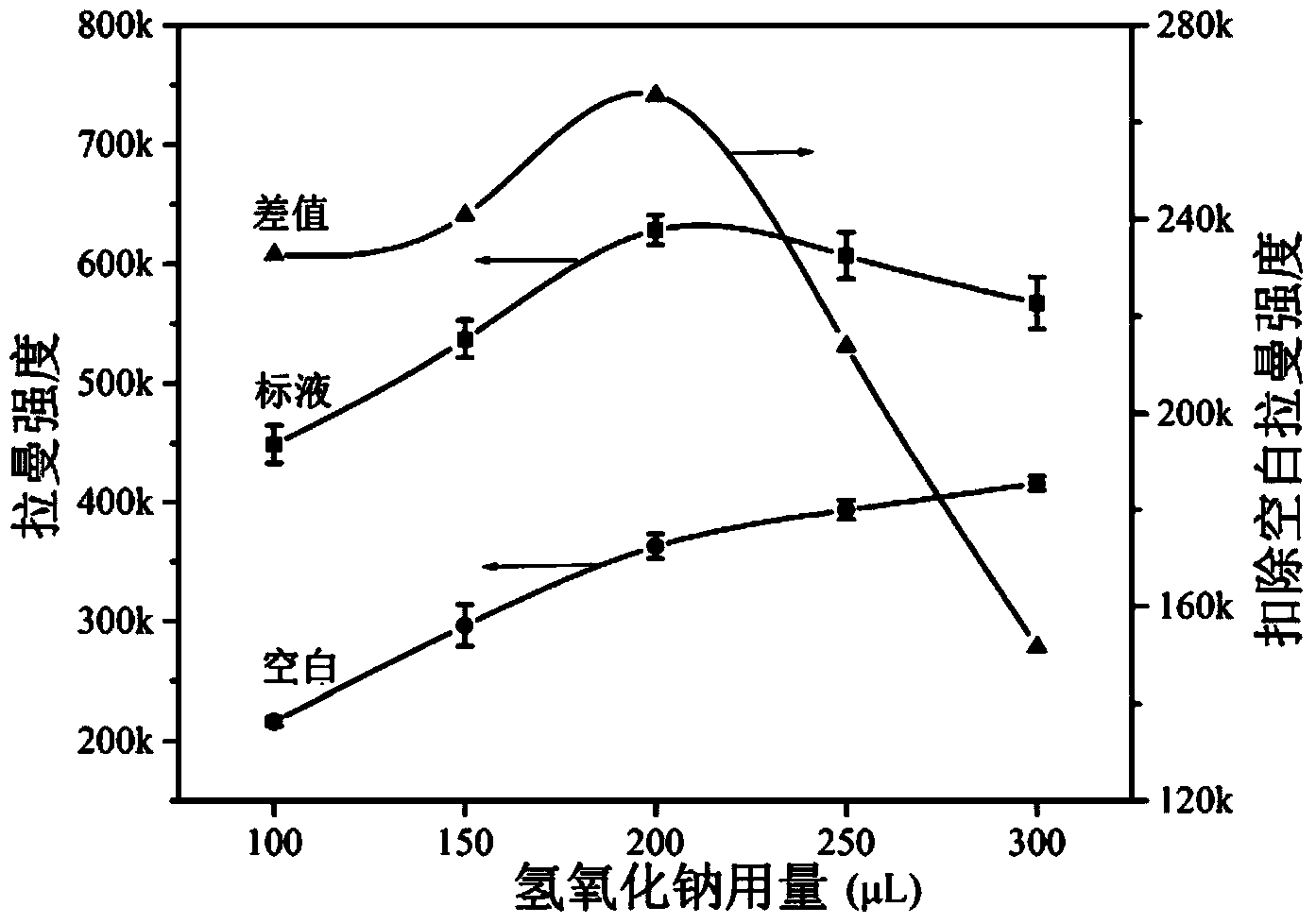

[0029] Add 500μL of the standard solution into a 5mL centrifuge tube, add 100-300μL of 1.0mol / L NaOH solution and 200μL of 5g / L AHMT solution and mix well. Derivatize for 20min at room temperature. Take out 10 μL and add 500 μL of the enhancement reagent, mix for 2.5 min at room temperature, and measure the Raman strength. At the same time, a blank experiment was performed. Calculate and deduct the blank Raman intensity, the influence of 1.0mol / L NaOH solution dosage on Raman intensity is as follows: figure 2 Shown. In the range of 100-300μL, with the increase of the amount of NaOH solution, the blank Raman intensity first increases and then decreases, reaching the maximum when the amount is 200μL. Therefore, the optimal amount of 1.0mol / L NaOH solution in the derivatization reagent is 200μL.

Embodiment 2

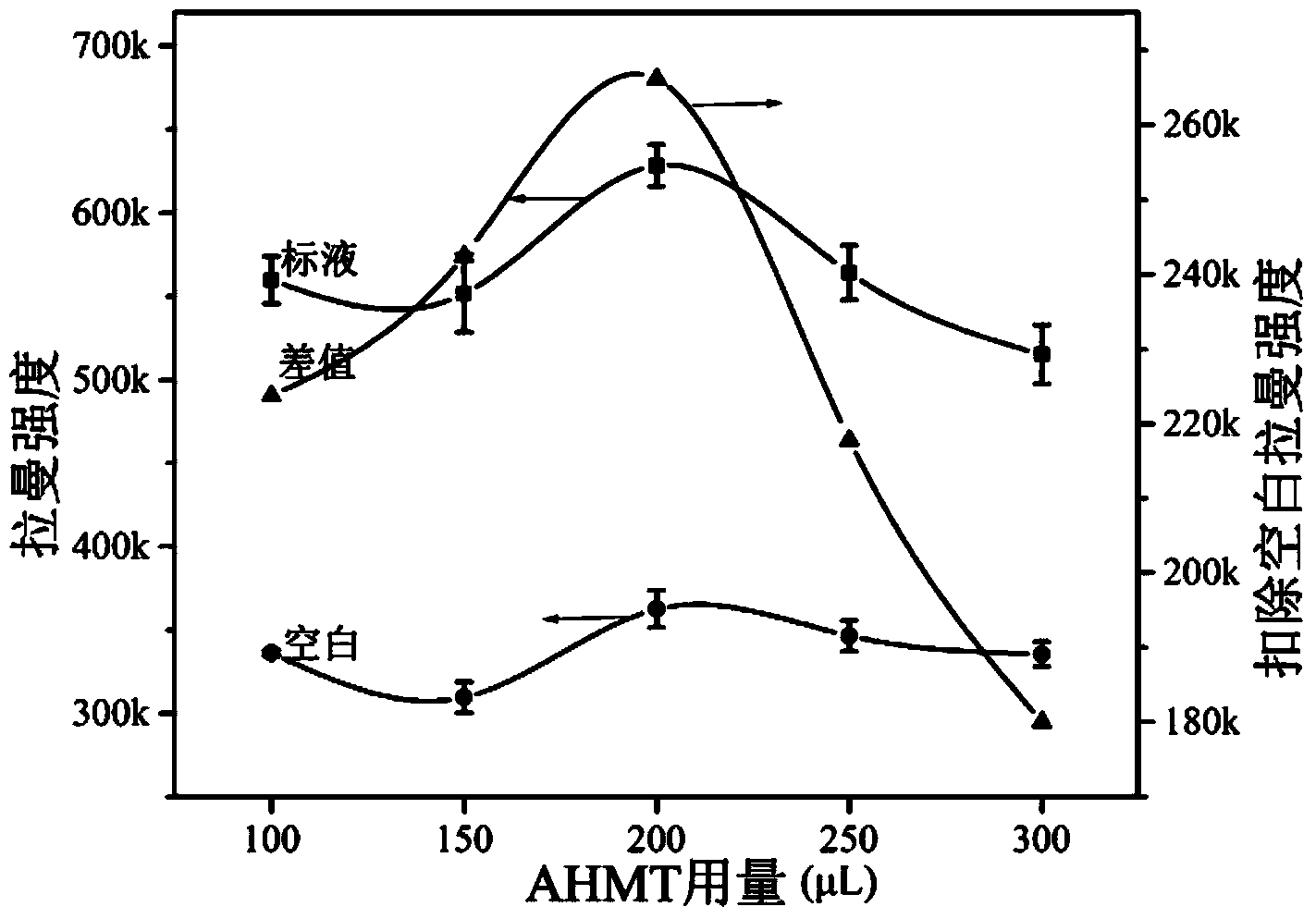

[0031] Add 500μL of the standard solution to a 5mL centrifuge tube, add 200μL of 1.0mol / L NaOH solution and 100~300μL of 5g / L AHMT solution and mix well. Derivatize for 20min at room temperature. Take out 10 μL and add 500 μL of enhancer reagent, mix for 2.5 min at room temperature, and measure the Raman intensity. At the same time, a blank experiment was performed. Calculate and deduct the blank Raman strength, the effect of the amount of 5g / L AHMT solution on the Raman strength is as image 3 Shown. In the range of 100-300μL, as the dosage of AHMT solution increases, the blank Raman intensity will increase first and then decrease, reaching the maximum when the dosage is 200μL. Therefore, the optimal amount of 5g / L AHMT solution in the derivatization reagent is 200μL.

Embodiment 3

[0033] Add 500μL of standard solution to a 5mL centrifuge tube, add 200μL of 1.0mol / L NaOH solution and 200μL of 5g / L AHMT solution and mix well. Derivatize at room temperature for 10-30min. Take out 10 μL and add 500 μL of the enhancement reagent, mix for 2.5 min at room temperature, and measure the Raman strength. At the same time, a blank experiment was performed. Calculate the blank Raman intensity, the influence of the derivatization time on the Raman intensity is as Figure 4 Shown. In the range of 10 to 30 minutes, with the increase of time, the blank Raman intensity gradually increases, and reaches the maximum at 20 minutes, and there is no change in the extended time, which proves that the derivatization is complete in 20 minutes. Therefore, the best time for derivatization is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com