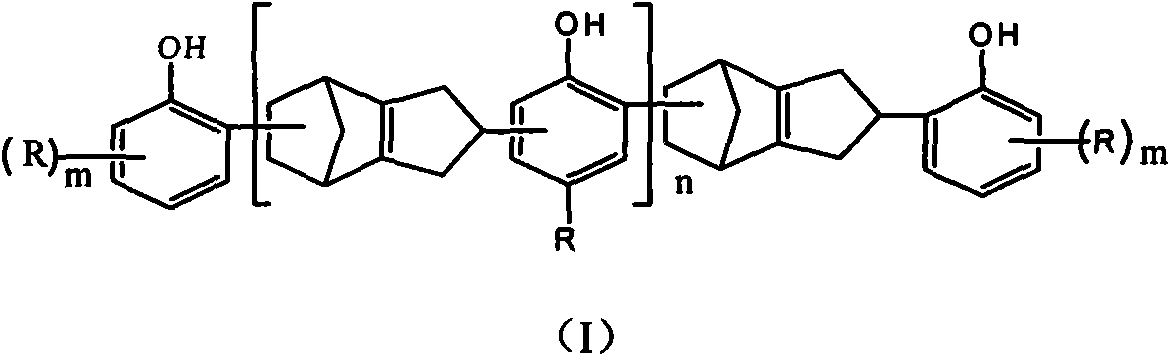

Resin for improving rubber tear resistance and preparation method thereof

A technology of resin and rubber composition, which is applied in the field of phenol-dicyclopentadiene resin and its preparation, can solve problems such as complex production, and achieve the effects of excellent product performance, low price, and abundant raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

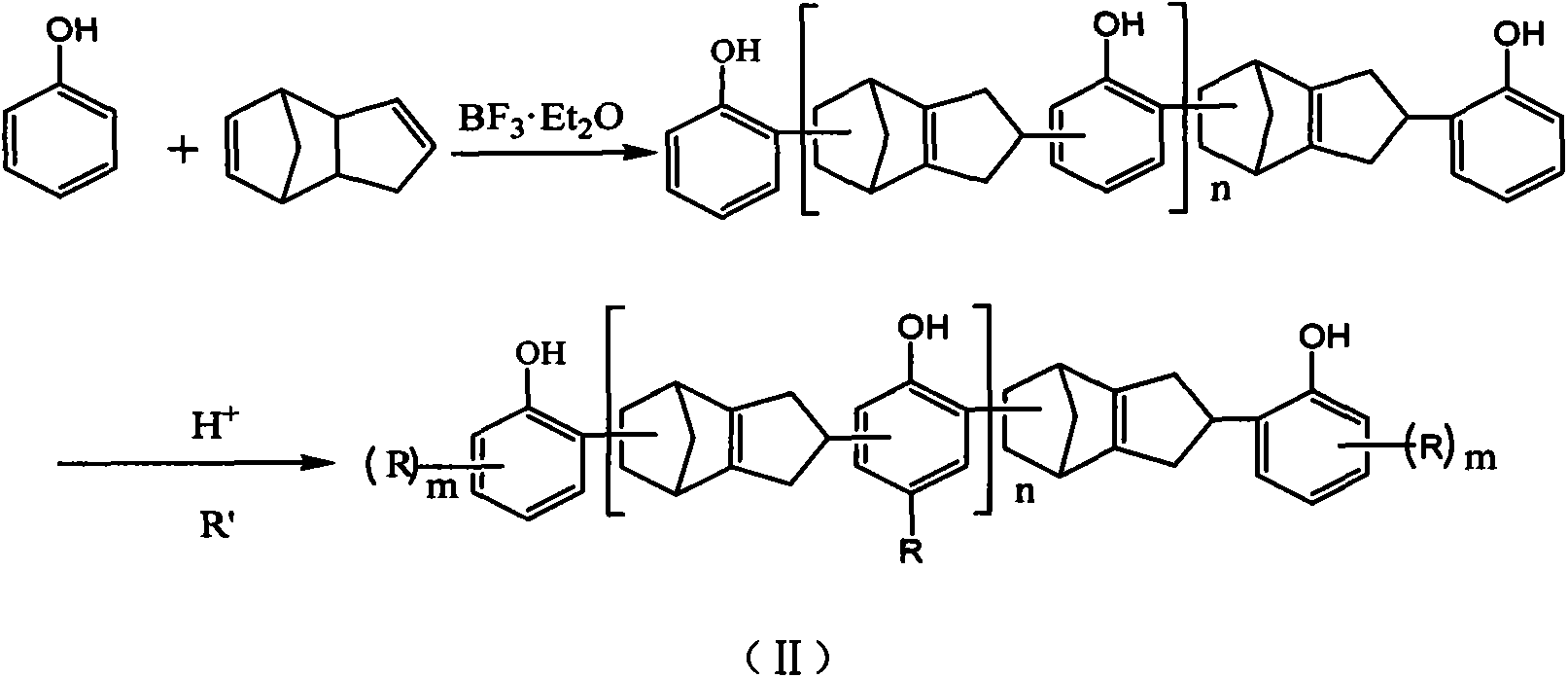

Method used

Image

Examples

preparation example Construction

[0033] 1.1 Preparation and performance test of phenolic resin

[0034] Softening point test:

[0035] According to the standard ASTM D3461-97 (2007), the FP900 calorific value analysis system is used to test the softening point of phenolic resin.

Embodiment 1

[0037] Add 1mol of phenol, 50ml of toluene, and BF to a 500ml round bottom flask equipped with a stirring device, a thermometer and a reflux condenser. 3 ·Et 2 O catalyst 5ml, pass N 2 Protect, warm up to 80°C to completely dissolve phenol, slowly add 1mol DCPD dropwise, control the reaction temperature at 110-120°C, after 3h reaction, add 2mL ethanol to quench the catalyst, change to distillation state to distill toluene solvent and then return to reflux state. Add 0.5 g of dodecyl benzene sulfonic acid, add 0.5 mol of a-methyl styrene drop by drop, react for 5 hours, change the condenser from reflux state to distillation state, heat the reactant to 200 ℃, slowly turn on the vacuum to the maximum vacuum The temperature is maintained for 15 minutes, and the material is discharged after neutralization with sodium hydroxide. A-methylstyrene modified phenol-DCPD resin is obtained. The softening point of the resin was determined to be 109.2°C.

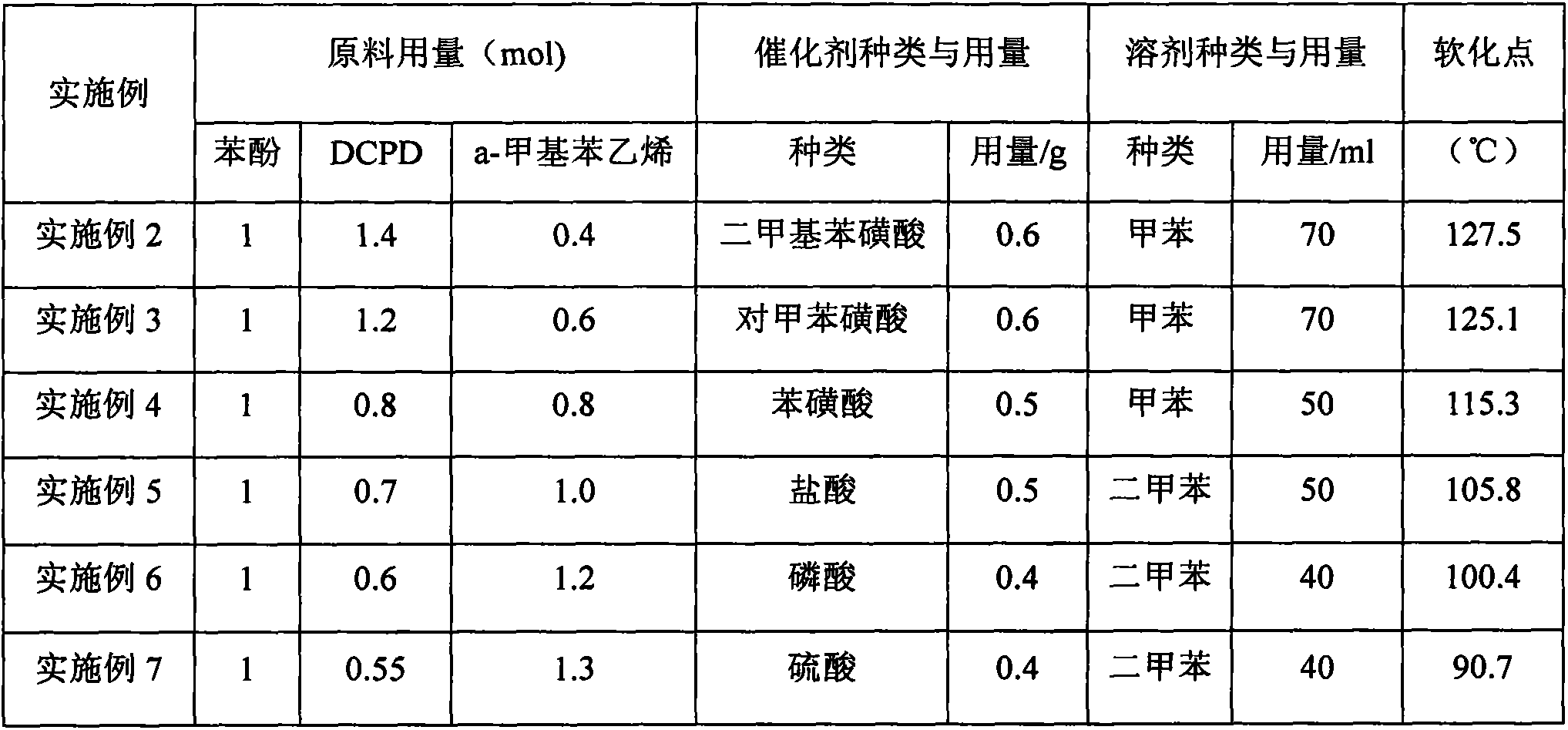

Embodiment 2~7

[0039] The molar ratio of phenol and DCPD, the amount and type of catalyst and solvent were changed, and the resin preparation process in Example 1 was repeated. For specific data, see Table 3 below:

[0040] table 3

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com