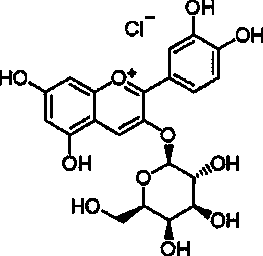

Production process of blueberry extract with more than or equal to 25% of anthocyanin

A technology of blueberry extract and production process, which is applied in the chemical industry, food science, sustainable manufacturing/processing, etc., can solve the problem that the extraction and purification process is difficult to achieve a content of ≥ 25%, and achieve energy saving, process simplification, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A production process of blueberry extract with anthocyanins ≥ 25%, the process includes: soaking blueberry raw materials in acid water, high-voltage electric field extraction, rough filtration, fine filtration, reverse osmosis, AB-8 resin refining, reverse osmosis, spray drying, Finished product; the specific steps are:

[0026] (1) High-voltage electric field extraction: take 100 parts by mass of blueberry raw materials, crush them through a 40-mesh sieve, add 10 times the mass parts of blueberry raw materials, and soak in acidic water with pH 2 at room temperature for 1 hour, and then use a high-voltage electric field extraction device to extract 12 pulses in the electric field. Extract under the condition of intensity of 45kV / cm, extraction time is 2 hours;

[0027] Above-mentioned acid water used is oxalic acid aqueous solution or acetic acid aqueous solution etc.

[0028] (2) Filtration: After the above-mentioned extracted liquid is roughly filtered with a 200-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com