A polymer degradation agent

A technology of degrading agent and polymer, which is applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as clogging, and achieve the effect of simple process, recovery of seepage capacity, and good application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

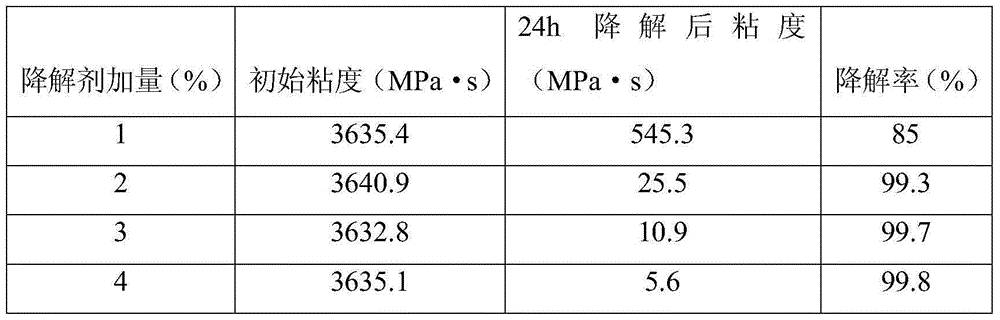

[0010] Polymer Degradant for Polymer Degradation Test

[0011] 70% ammonium sulfate, 10% ammonium persulfate, 3% ATMP, 2% EDTA, 3% OP, 2% dodecyl dimethyl benzyl ammonium chloride and 10% water were mixed to prepare a polymer degradation agent. After preparing the polymer solid powder and on-site sewage into a viscous system of 4000ppm, the viscosity measured by Brookfield viscometer at room temperature is above 3600mpa. As shown in Table 1 below:

[0012] Table 1 Polymer degradation experiment data table

[0013]

[0014] It can be seen from Table 1 that after adding 2% to 4% polymer degradation agent, the degradation rate can reach more than 99% after standing for 24 hours, and the degradation effect is very good. Unblocking caused by polymer is feasible.

Embodiment 2

[0016] Polymer Degradant for Particle Degradation Test

[0017] 70% ammonium sulfate, 5% ammonium persulfate, 1% ATMP, 2% EDTA, 3% OP, 2% dodecyl dimethyl benzyl ammonium chloride and 17% water were mixed to prepare a polymer degradation agent. Add 2% of the above-mentioned polymer degradation agent to the blockage of the profile control oil well, stir it, and observe it for 34 hours. It is found that the blockage is dispersed into many small blocks, and the small blocks are suspended after stirring, indicating that the polymerization The biodegradant is also suitable for plugging removal of profile control wells.

Embodiment 3

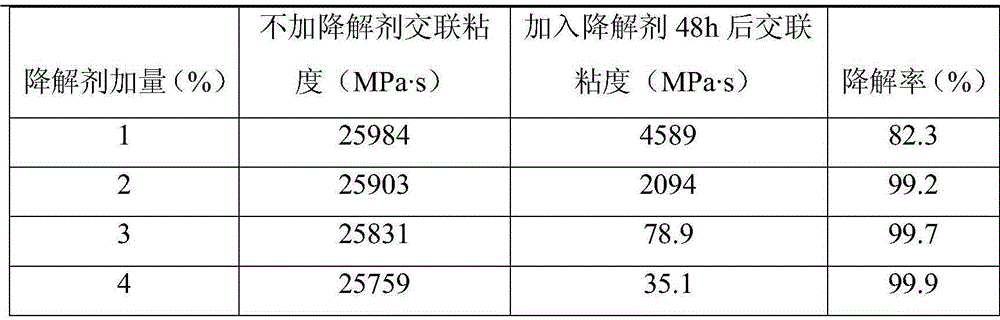

[0019] Polymer Degradant Used in Crosslinker Degradation Test

[0020] 70% ammonium sulfate, 5% ammonium persulfate, 3% ATMP, 1% EDTA, 3% OP, 2% dodecyl dimethyl benzyl ammonium chloride and 16% water were mixed to prepare a polymer degradation agent. After the cross-linking agent is compatible with the sewage polymer system, the cross-linking viscosity reaches more than 25000mpa.s, and different amounts of polymer degradation agents are added to observe for 30 hours. After degradation, the viscosity is between 4589mpa s and 35.1mpa s, and the degradation rate is 82.3% to 99.9%. The experimental data are shown in Table 2 below:

[0021] Table 2 Cross-linking agent degradation experiment data table

[0022]

[0023] It can be seen from Table 2 that the degradation effect of the polymer degradation agent on the series of crosslinking agents is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com