A kind of composite flora for degrading electroplating wastewater and its preparation method

A technology of complex bacterial flora and electroplating wastewater, applied in the direction of microbial-based methods, biochemical equipment and methods, metallurgical wastewater treatment, etc., can solve the problems of species, small quantity, complex wastewater components, etc., and achieve good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

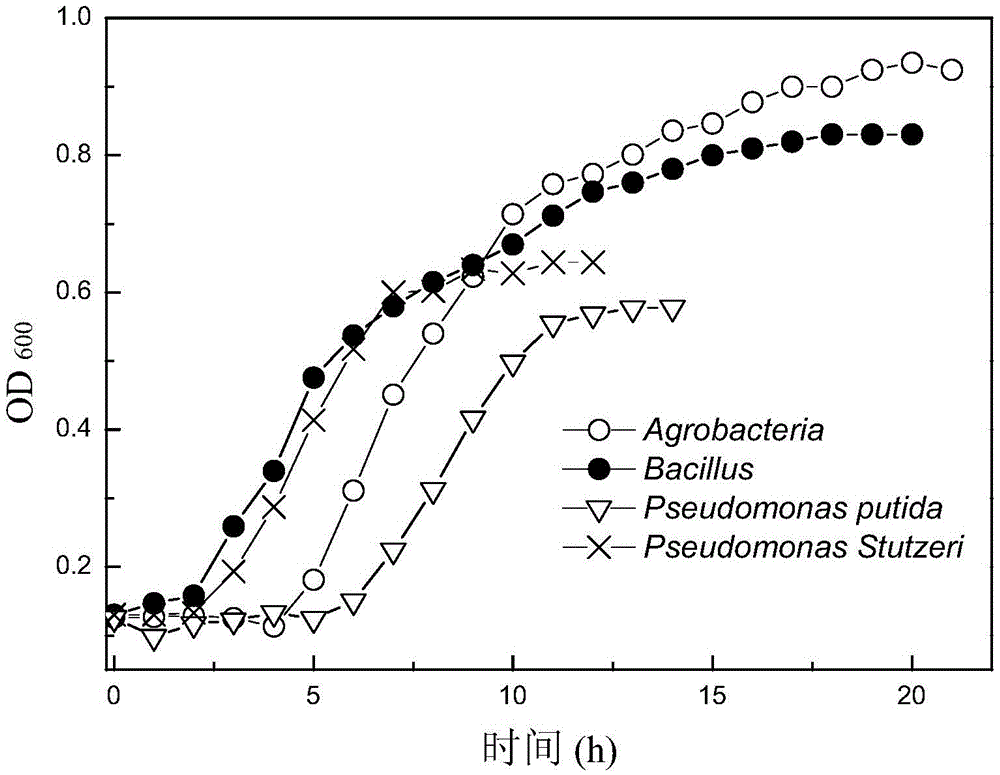

[0025] Agrobacterium sp., Bacillus sp., Pseudomonasputida., Pseudomonasstutzeri. were picked respectively (isolated from the sludge at the outlet of the electroplating factory 1 ring of the obtained) four kinds of bacteria, which were transferred to 20mL nutrient solution containing 1.5g / L beef extract, 1.0g / L glucose, 5.5g / L tryptone, 3.0g / L yeast powder, pH6 .5, and the rest is water), each type of bacteria was cultured at 27°C for 1 day, and then the cultured four kinds of bacteria were inoculated at a volume ratio of 1:9 (bacteria and proliferation medium) The suspension was placed in a container containing 500 mL of sterile proliferation medium, cultured at 35° C. for 1 day, centrifuged at 6000 rpm for 10 min, and logarithmic growth phase cells of the above four bacteria were obtained respectively. Adopt different proliferation nutrient medium to cultivate, wherein, the nutrient medium of Agrobacterium and bacillus is beef extract 3.0g / L, tryptone 4.0g / L, the rest is wate...

Embodiment 2

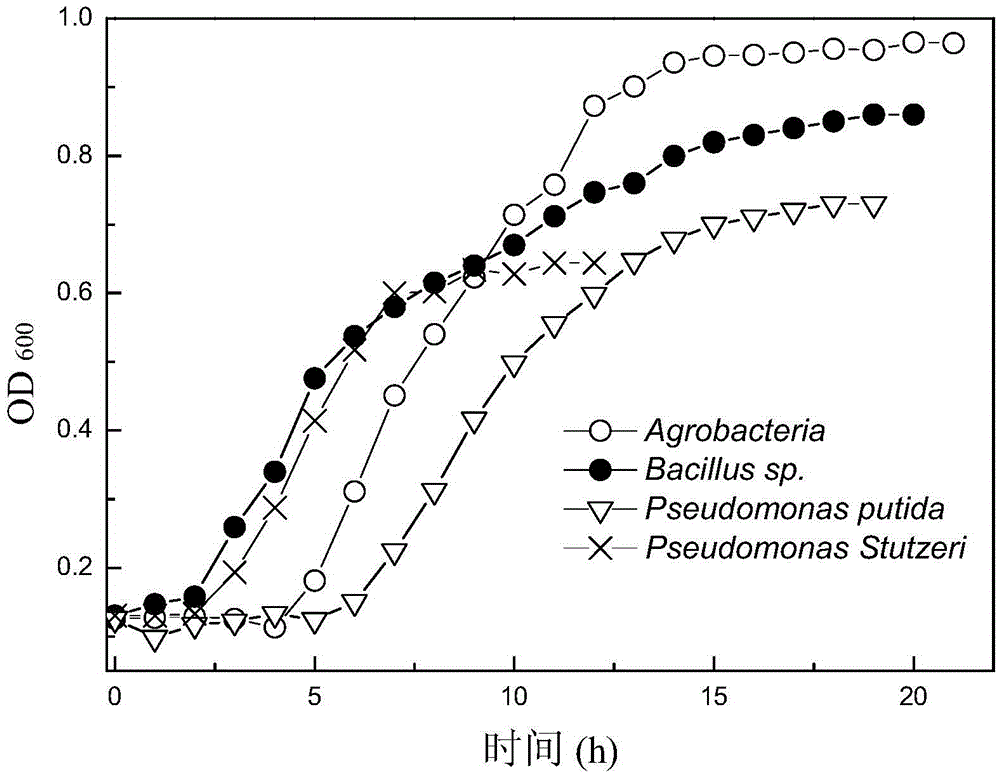

[0033] Pick 2 rings of four kinds of bacteria: Agrobacterium sp., Bacillus sp., Pseudomonasputida., Pseudomonasstutzeri. (from the drainage of the electroplating factory mouth

[0034] Separated from the sludge), transfer them to 30mL nutrient solution (the composition is 2.0g / L beef extract, 1.5g / L glucose, 6.5g / L tryptone, 3.5g / L yeast powder, pH7 .5, the rest is water and essential impurities), each type of bacteria was cultured at 30°C for 2 days, and then the cultured four kinds of bacteria were respectively mixed in a volume ratio of 1:10 (bacteria and Proliferation medium) Inoculate the bacterial suspension into a container containing 500mL of sterile proliferation medium, culture at 35°C for 2 days, centrifuge at 7000rpm for 15min, and obtain the logarithmic growth phase cells of the above four bacteria respectively . Among them, four different bacteria adopt different proliferation medium, wherein the nutrient medium of Agrobacterium and rod-shaped bacteria is beef ...

Embodiment 3

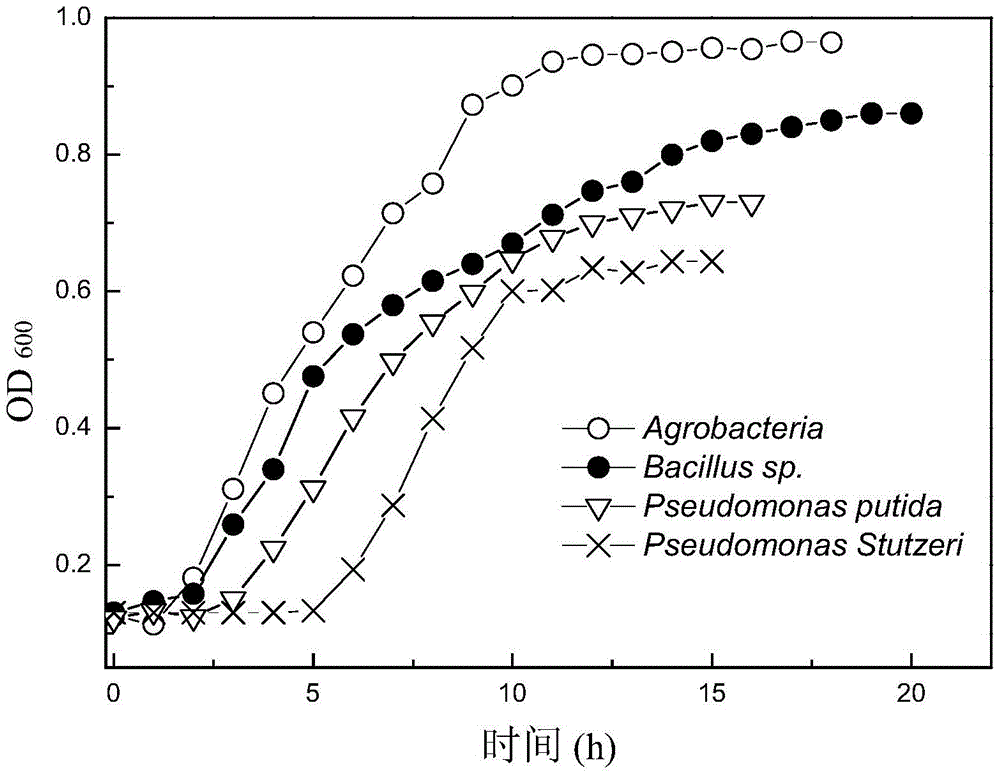

[0043] Pick four rings of bacteria respectively: Agrobacterium sp., Bacillus sp., Pseudomonasputida., Pseudomonasstutzeri. (from the drainage of the electroplating factory Separation from the sludge in the mouth), transfer them to 25mL nutrient solution (the composition is 1.7g / L beef extract, 2.0g / L glucose, 6.0g / L tryptone, 4.0g / L yeast powder, pH 7.0, the rest is water), each type of bacteria was cultured at 27°C for 2 days, and then the cultured four kinds of bacteria were inoculated at a volume ratio of 1:12 (bacteria and proliferation medium) The bacterial suspension was cultured at 30°C for 2 days in a container containing 450 mL of sterile growth medium, centrifuged at 6000 rpm for 15 min, and the logarithmic growth phase cells of the above four bacteria were obtained respectively. Among them, four different bacteria adopt different proliferation medium, wherein the nutrient medium of Agrobacterium and bacillus is beef extract 4.0g / L, tryptone 4.5g / L, and the rest is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com