Photoconductive switch manufacturing method based on SiC substrate

A technology for a photoconductive switch and a manufacturing method, which is applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem that the photoconductive switch cannot meet the performance requirements of high power, ultra-high speed, thermal stability, etc., and achieves a reduction in production. Cost, reduce process flow, improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail

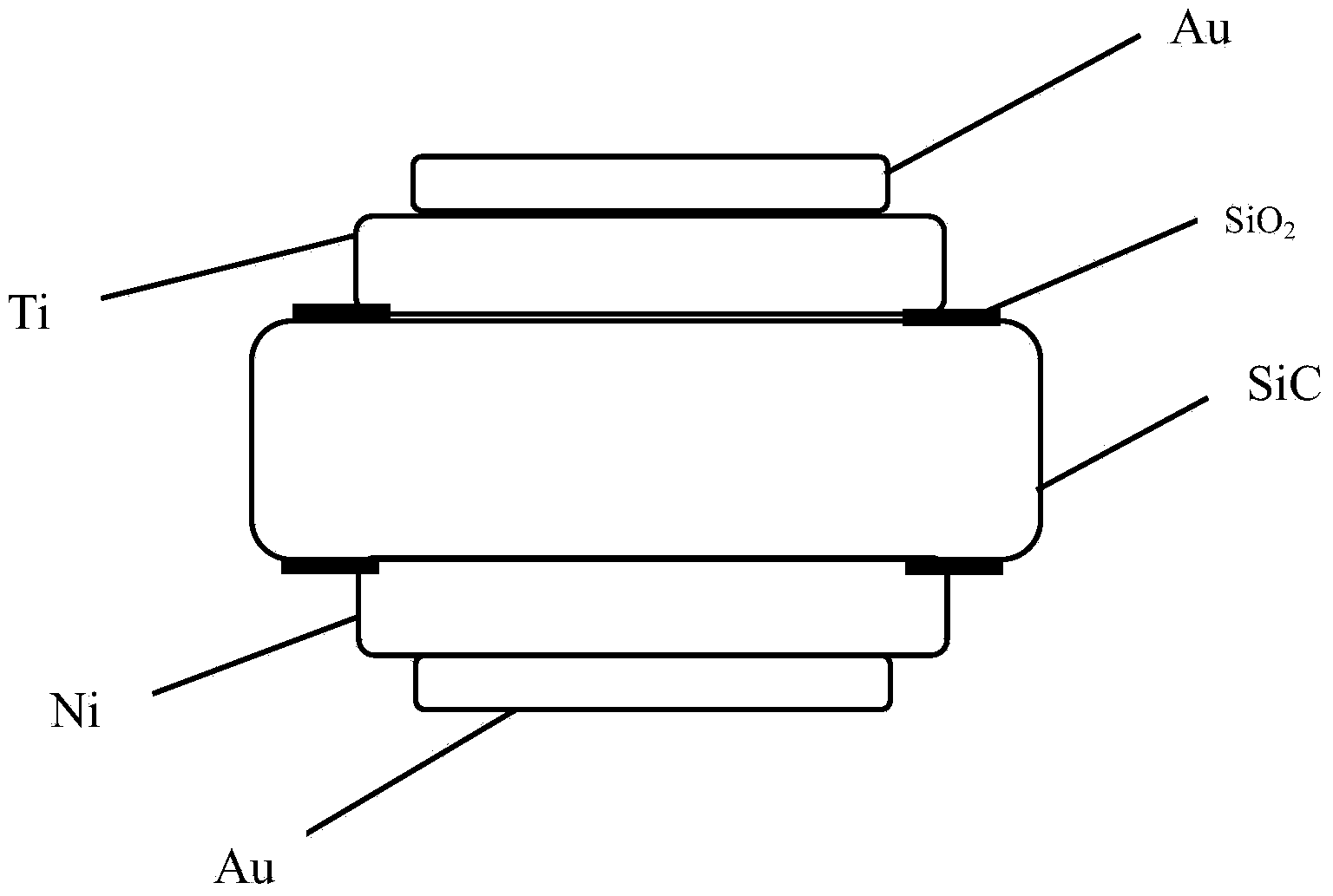

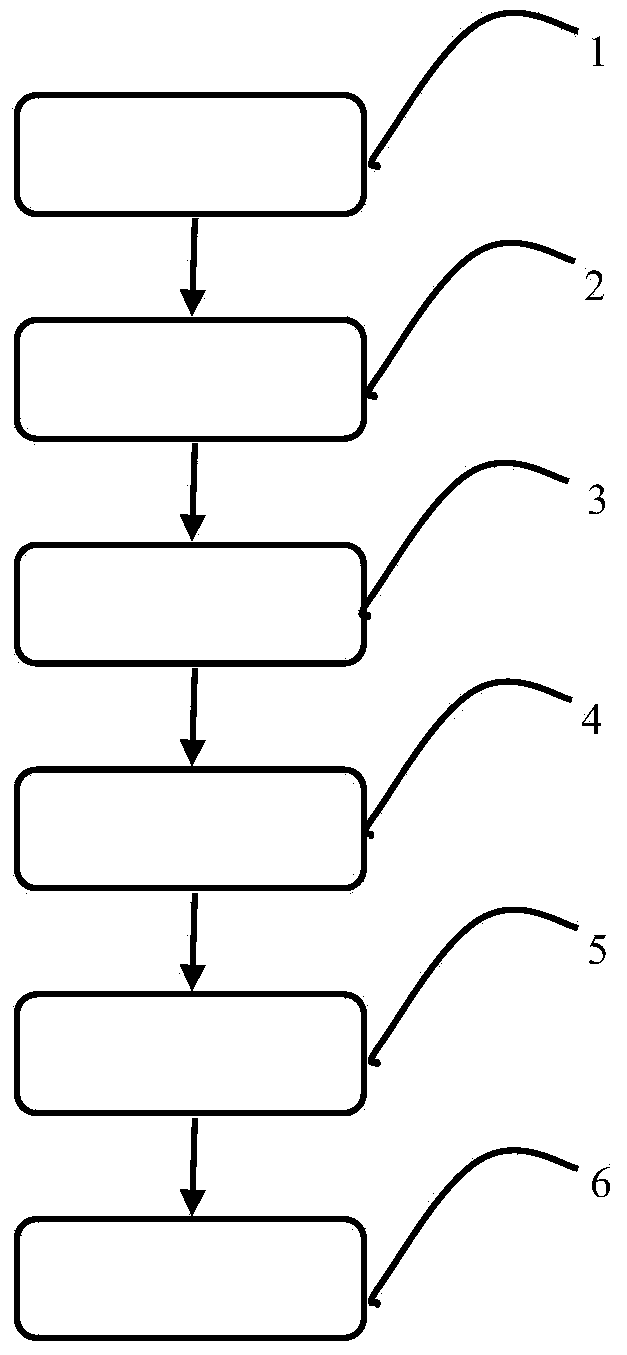

[0013] A method for manufacturing a photoconductive switch based on a SiC substrate according to the present invention (as shown in the attached figure 1 , 2 shown), including the following steps:

[0014] Step 1, SiC substrate: the substrate is a SiC wafer, cleaned by a standard semiconductor process.

[0015] Step 2, SiO 2 Insulation protective layer: Wet oxygen is passed into the tube furnace, 10-25sccm, temperature 1200-1350℃, oxidized to SiO at constant temperature for 5-10 hours 2 film; then open the window by photolithography, and use the microelectronics dry etching process RIE Ar high-energy ions to roughen the substrate surface.

[0016] Step 3, preparing Ti electrode thin film: using high vacuum magnetron sputtering equipment, depositing a layer of Ti electrode thin film, the thickness of which is controlled at 100-140nm.

[0017] Step 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com