Flexible organic electroluminescent device and preparation method thereof

An electroluminescent device, an organic technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as limited conductivity, high surface resistance, and affecting the luminous efficiency of flexible organic electroluminescent devices. Achieve low raw material cost, increase electrical conductivity, and improve electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

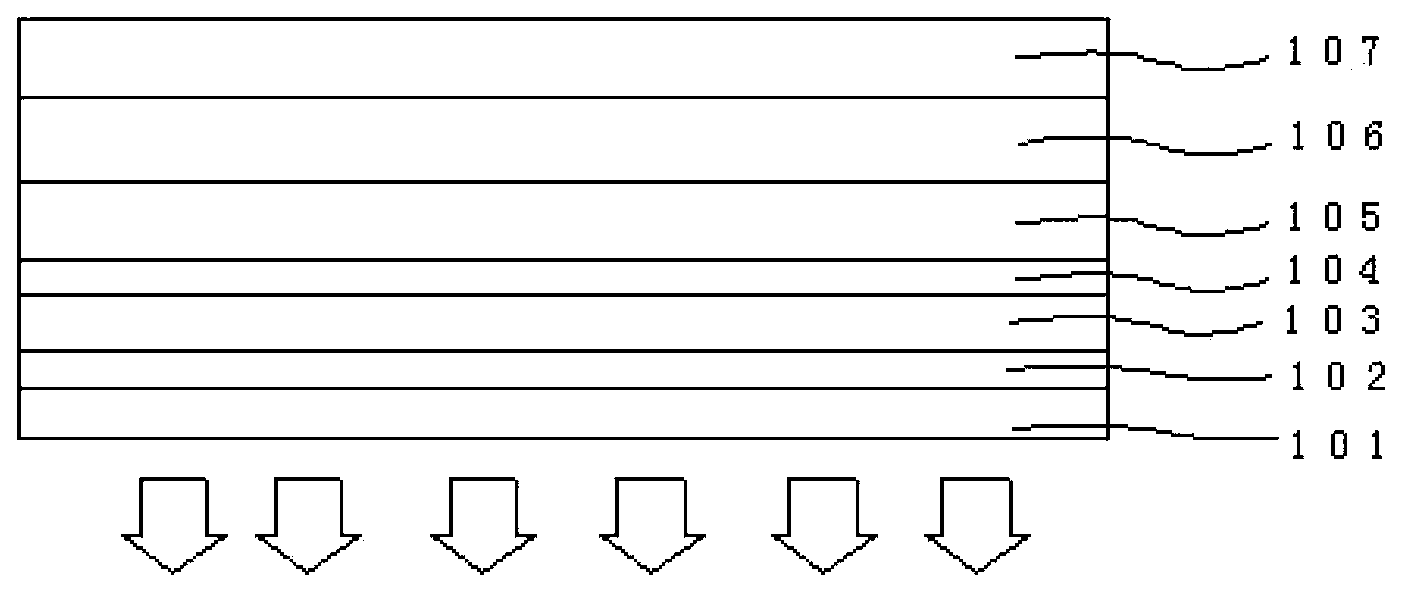

[0071] The present invention also provides a method for preparing a flexible organic electroluminescent device, comprising the following steps:

[0072] (1) After cleaning the flexible substrate, air-dry it and set it aside;

[0073] (2) Add the suspension of single-layer graphite to the aqueous solution of poly-3,4-dioxyethylene thiophene and polybenzenesulfonate mixture, and stir to obtain graphene, poly-3,4-dioxyethylene thiophene and polyphenylene sulfonate The mixed solution of sulfonate, and then add polar aprotic solvent, stir evenly to obtain an anode solution system; wherein, the mass ratio of graphene, poly(3,4-dioxyethylenethiophene) and polybenzenesulfonate is 0.003-0.158 :2:1;

[0074] (3) Spin-coat the anode solution system obtained in step (2) on the surface of the flexible substrate treated in step (1), then place the flexible substrate at 130-160°C for 5-15 minutes, and cool And remove the excess solvent to obtain a flexible anode;

[0075] (4) On the flexi...

Embodiment 1

[0094] A method for preparing a flexible organic electroluminescent device, comprising the following steps:

[0095] (1) Select polyethylene naphthalate (PEN) film as a flexible substrate, put it in deionized water containing detergent for ultrasonic cleaning, clean it with deionized water, put it in isopropanol, In acetone and carry out ultrasonic treatment, then dry with nitrogen, standby;

[0096] (2) Add the suspension of single-layer graphite with a concentration of 0.05mg / mL to the PEDOT / PSS aqueous solution with a mass fraction of 1.0%, and stir to obtain a graphene-PEDOT / PSS mixture, and then press the volume ratio of 20:1 Add the concentration of 98% dimethyl sulfoxide solution to the graphene-PEDOT / PSS mixed solution, and after mixing, ultrasonic treatment at room temperature for 10 minutes to obtain a uniform anode solution system; wherein, graphene, poly 3, The mass ratio of 4-dioxyethylenethiophene to polybenzenesulfonate is 0.006:2:1;

[0097] (3) Put the flexi...

Embodiment 2

[0107] A method for preparing a flexible organic electroluminescent device, comprising the following steps:

[0108] (1) Select polyethylene terephthalate (PET) film as the flexible substrate, soak it in isopropanol for 15 minutes, take it out, soak it in acetone for 15 minutes, and then wash it with distilled water Clean and dry at room temperature for later use;

[0109] (2) Add 2.0 mg / mL single-layer graphite suspension to 5% PEDOT / PSS aqueous solution, stir to obtain graphene-PEDOT / PSS mixture, and then press the ratio of 10:1 by volume In graphene-PEDOT / PSS mixed solution, adding concentration is the dimethyl sulfoxide (DMSO) solution of 80%, after mixing, at room temperature supersonic treatment 15 minutes, obtains uniform anode solution system; Wherein, graphene, poly 3 , The mass ratio of 4-dioxyethylenethiophene to polybenzenesulfonate is 0.158:2:1;

[0110] (3) Put the flexible substrate treated in the step (1) on the homogenizer, spin-coat the anode solution syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com