Method for preparing air electrode, air electrode and battery comprising air electrode

An air electrode and air side technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve the electrochemical performance can not meet the actual needs, high overpotential and other problems, to achieve The effect of low raw material prices, increased energy density, and environmentally friendly preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

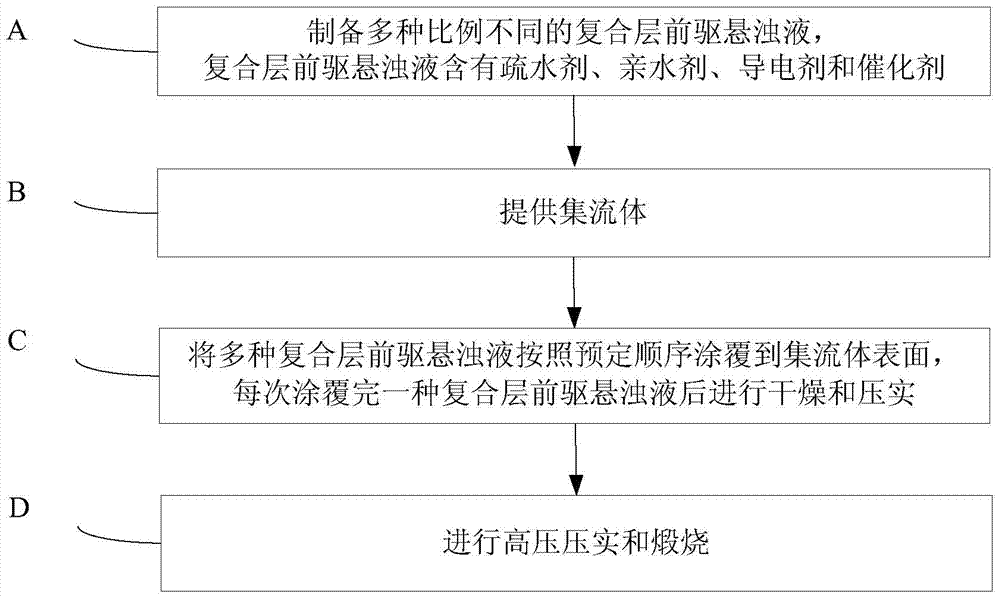

[0043] The first aspect of the present invention proposes a kind of preparation method of air electrode, such as image 3 As shown, the following steps may be included:

[0044] A. Prepare multiple composite layer precursor suspensions with different ratios. The composite layer precursor suspension contains hydrophobic agents, hydrophilic agents, conductive agents and catalysts.

[0045] The hydrophobic agent in the composite layer precursor suspension can be one or a combination of polytetrafluoroethylene emulsion and Nafion emulsion. Wherein, the Nafion emulsion refers to the emulsion formed by perfluorosulfonic acid-polytetrafluoroethylene copolymer substances in water.

[0046] The hydrophilic agent in the composite layer precursor suspension can be one or more of hydrophilic molecular sieves and polyalcohols (such as polyvinyl alcohol). Among them, hydrophilic molecular sieves also have the advantage of resistance to oxidation.

[0047] The conductive agent in the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com