Laying hen feed taking nuts as feed components and classified feeding method of laying hen

A layer chicken feed and composition technology, which is applied in the field of layer feed and layer hen classification breeding, can solve the problems of difficult calculation of moulting cost, disease resistance, lower egg production rate, and poor grasp of moulting technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

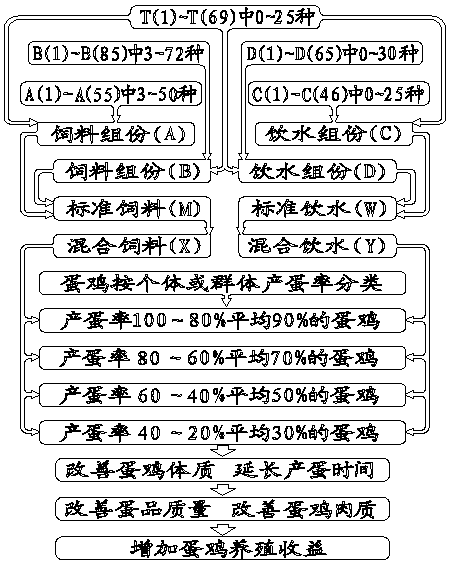

Method used

Image

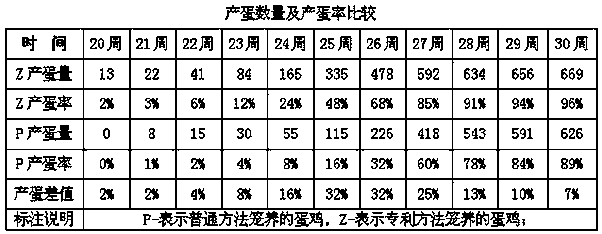

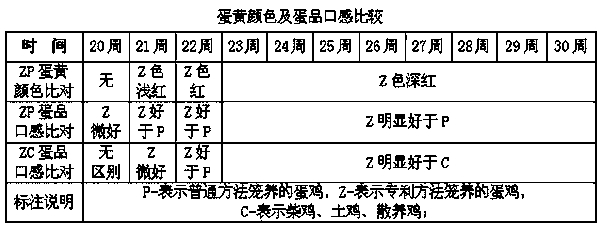

Examples

Embodiment 1

[0086] It is characterized in that the general component (T) is pre-assigned to (A) (B) (C) (D) components, melon seeds (A3), peanut kernels (A4), hemp seeds (A25), mushroom feet ( B12), dried carrots (B61) are mandatory;

[0087] Feed component (A) options and proportions are: almond (A1) 0 or 1-50, peach kernel (A2) 0 or 1-50, melon seed kernel (A3) 10-100, peanut kernel (A4) 10-100 , walnut kernel (A5) 0 or 1~50, pine nut kernel (A6) 0 or 1~50, hazelnut kernel (A7) 0 or 1~50, cashew kernel (A8) 0 or 1~50, jujube kernel (A9) 0 or 1~50, Yu Liren (A10) 0 or 1~50, Yizhiren (A11) 0 or 1~50, coix seed (A12) 0 or 1~50, lotus seed kernel (A13) 0 or 1~50, Oil sunflower kernel (A14) 0 or 10-100, perilla (A15) 0 or 1-50, millet (A16) 0 or 10-100, millet (A17) 0 or 10-100, sorghum (A18) 0 or 10-100, rye (A19) 0 or 10-100, buckwheat (A20) 0 or 10-100, oat (A21) 0 or 10-100, barley (A22) 0 or 10-100, barnyard (A23) 0 or 10-100, acorns (A24) 0 or 10-100, hemp seeds (A25) 10-100, safflo...

Embodiment 2

[0121] Embodiment 2 is characterized in that: feed component (A) is made of melon seed kernel (A3), peanut kernel (A4), pine nut kernel (A6), Yizhi kernel (A11), lotus seed kernel (A13), perilla kernel (A15) , millet (A16), millet (A17), sorghum (A18), rye (A19), buckwheat (A20), barnyard millet (A23), hemp seed (A25), safflower seed (A26), black japonica rice (A29 ), chestnut (A31), sesame (A34), red bean (A35), soybean (A37), black bean (A38), meat and bone meal (A45), fish oil (A46), garlic powder (A48), pine needle powder (A49), Maifan stone powder (A50), Gorgon fruit (T28); Feed component (B) consists of silkworm chrysalis (B1), oyster (B5), shrimp (B6), kelp (B7), laver (B8), black fungus (B11 ), mushroom feet (B12), cucumber seeds (B19), pumpkin seeds (B20), dried wolfberry (B25), dried red dates (B26), dried hawthorn (B27), black mulberries (B30), rose berries (B34) , raspberry (B39), golden cherry (B42), brocade lantern (B46), myrtle (B51), black rice (B53), blueberr...

Embodiment 3

[0122] Embodiment 3 is characterized in that: feed component (A) is made of almond (A1), melon seed kernel (A3), peanut kernel (A4), puzzle kernel (A11), lotus seed kernel (A13), white-perilla kernel (A15 ), millet (A16), millet (A17), red-sorghum (A18), oats (A21), barnyard millet (A23), hemp seeds (A25), safflower seeds (A26), lily (A33), sesame ( A34), soybeans (A37), white lentils (A41), collagen (A43), fish oil (A46), garlic powder (A48), pine needle powder (A49), salt + medical stone powder (A50); feed components ( B) Silkworm chrysalis (B1), shrimp (B6), seaweed (B8), black fungus (B11), mushroom feet (B12), white fungus (B14), day lily (B17), cucumber seeds (B19), grape seeds (B24), dried wolfberry (B25), dried red dates (B26), dried hawthorn (B27), black mulberry (B30), monk fruit (B31), sea buckthorn fruit (B32), raspberry (B39), golden cherry (B42) ), Brocade Lantern (B46), Berry Amaranth (B59), Myrtle (B51), Wufanzi (B53), Blueberry-Du Persimmon-Bilberry (B54), Pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com