A kind of microbubble generator and its manufacturing method and application

A technology of a microbubble generator and a manufacturing method, which is applied in the field of microfluidics, can solve problems such as difficult multiple microbubbles, small heat source area, etc., and achieve low cost and effective, good photothermal characteristics, and good photothermal conversion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

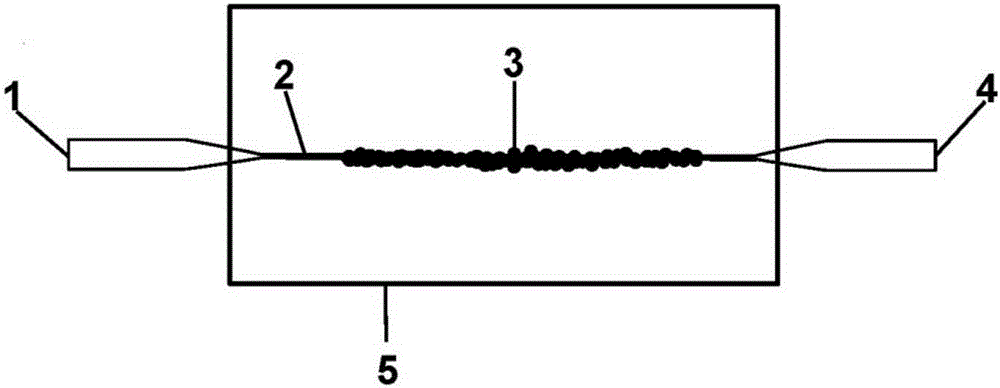

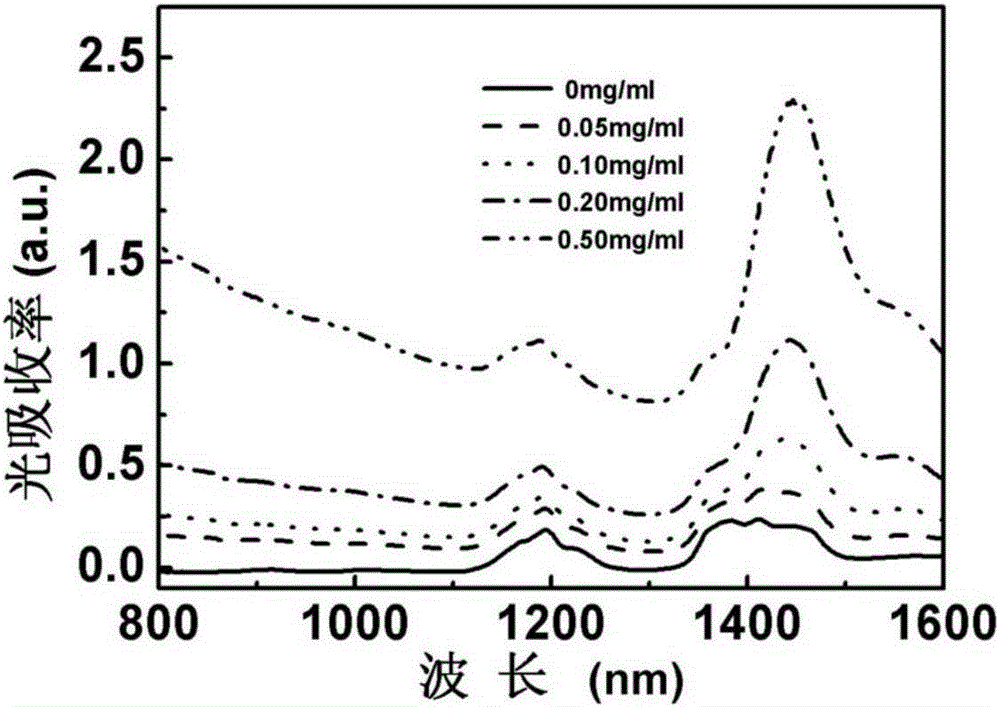

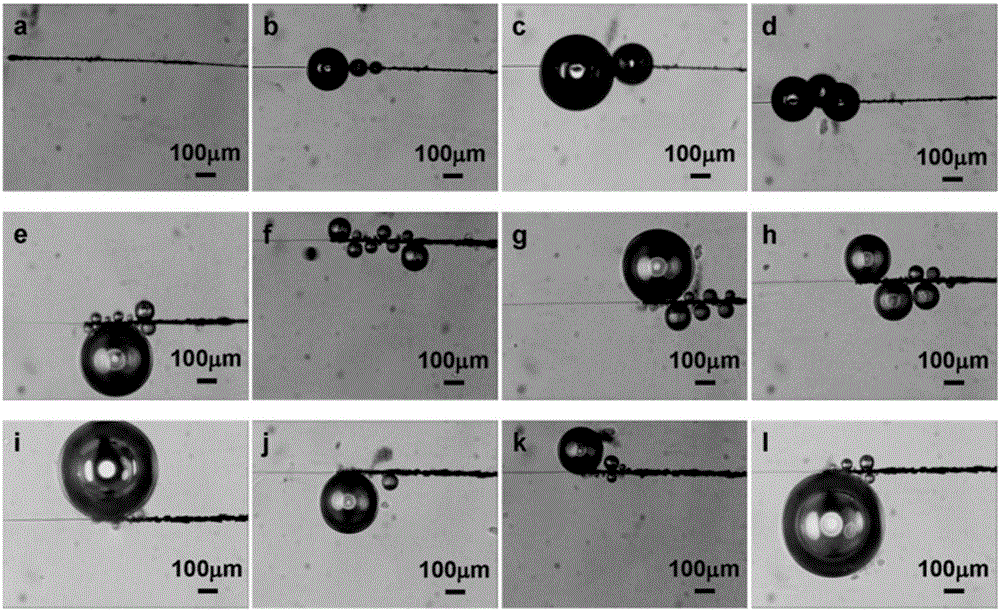

[0043] A microfiber with a diameter of 3.0 μm and a length of 1.2 mm was drawn from a single-mode silica fiber (SMF-28, Corning, USA) by a high-temperature drawing method. Such as figure 1As shown, the micro-optical fiber 2 was immersed in a DMF dispersion of 0.05 mg / mL graphene oxide. Connect the amplified spontaneous emission broadband light source (ASE, 20mW, 1527-1566nm) to the erbium-doped fiber amplifier (EDFA, 1546-1562nm) to obtain an output optical signal with a wavelength of 1527-1566nm and a power of 40mW. The optical signal from the EDFA is input into the optical signal input port 1, and the graphene oxide in the dispersion is adsorbed on the surface of the micro-fiber 2 under the action of the optical gradient force and thermal convection, forming graphene oxide deposits 3, forming a linear heat source. Continue to pass through the light, and the light energy is continuously converted into heat energy, so that the temperature around the graphene oxide deposit 3 ...

Embodiment 2

[0047] A microfiber with a diameter of 1.8 μm and a length of 1.2 mm was drawn from a single-mode silica fiber by a high-temperature drawing method. Such as figure 1 As shown, the micro-optical fiber 2 was immersed in a DMF dispersion of 0.05 mg / mL graphene oxide. Connect the amplified spontaneous emission broadband light source (ASE, 20mW, 1527-1566nm) to the erbium-doped fiber amplifier (EDFA, 1546-1562nm) to obtain an output optical signal with a wavelength of 1527-1566nm and a power of 40mW. The optical signal from the EDFA is input into the optical signal input port 1, and the graphene oxide in the dispersion is adsorbed on the surface of the micro-fiber 2 under the action of the optical gradient force and thermal convection, forming graphene oxide deposits 3, forming a linear heat source. Continue to pass through the light, and the light energy is continuously converted into heat energy, so that the temperature around the graphene oxide deposit 3 continues to rise. Whe...

Embodiment 3

[0049] A microfiber with a diameter of 2.6 μm and a length of 1.5 mm was drawn from a single-mode silica fiber by a high-temperature drawing method. Such as figure 1 As shown, the micro-optical fiber 2 was immersed in a DMF dispersion of 0.05 mg / mL graphene oxide. Connect the amplified spontaneous emission broadband light source (ASE, 20mW, 1527-1566nm) to the erbium-doped fiber amplifier (EDFA, 1546-1562nm) to obtain an output optical signal with a wavelength of 1527-1566nm and a power of 40mW. The optical signal from the EDFA is input into the optical signal input port 1, and the graphene oxide in the dispersion is adsorbed on the surface of the micro-fiber 2 under the action of the optical gradient force and thermal convection, forming graphene oxide deposits 3, forming a linear heat source. Continue to pass through the light, and the light energy is continuously converted into heat energy, so that the temperature around the graphene oxide deposit 3 continues to rise. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com