Method for firing brick by using solid slag produced in electroplating wastewater treatment

A technology of electroplating wastewater and treatment agent, which is applied in the field of industrial solid waste treatment, can solve the problems of land occupation, large energy consumption, secondary pollution of the environment, and secondary pollution of the environment, so as to reduce treatment costs, save energy, and avoid secondary pollution. The effect of the investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

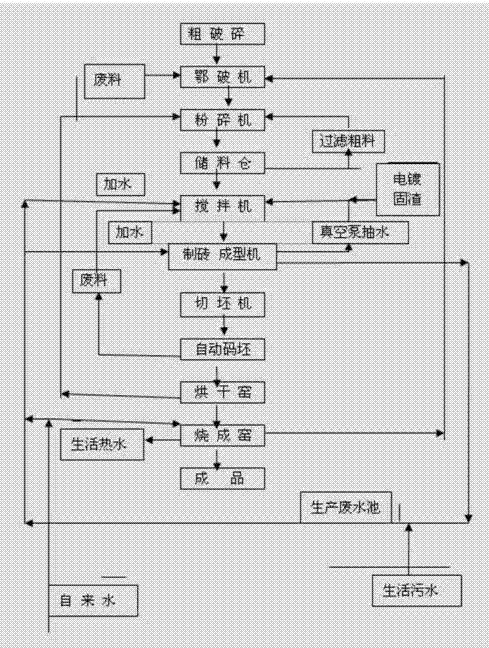

Image

Examples

Embodiment 1

[0022] A method of using physical and chemical methods to treat the solid slag produced by electroplating wastewater to make bricks. The electroplating wastewater first enters the adjustment pool for adjustment; then enters the reduction pool for reduction reaction. 3 Sodium metabisulfite, react for about 20 minutes to completely reduce hexavalent chromium to trivalent chromium; then enter the neutralization tank for neutralization reaction, add 1.0kg / m 3 QS electroplating wastewater treatment agent and 0.02kg / m 3 Amide, so that the pH value reaches 8, react for about 20 minutes; then enter the sedimentation tank for sedimentation and separation, the supernatant is discharged up to the standard, and the sediment is filtered by a plate and frame filter press to obtain a solid residue. The solid slag with a moisture content of 77.40% is mixed with 55% shale, 28% coal gangue and 5% raw coal in an amount of 12% and mixed evenly, extruded and dried in a drying furnace at 130°C for ...

Embodiment 2

[0029]A method of using physical and chemical methods to treat solid slag produced by electroplating wastewater to make bricks. The electroplating wastewater first enters the adjustment tank for adjustment, and then enters the reduction tank for reduction reaction. 3 Sodium metabisulfite, react for about 20 minutes to completely reduce hexavalent chromium to trivalent chromium; then enter the neutralization tank for neutralization reaction, add 1.5kg / m 3 QS electroplating wastewater treatment agent and 0.03kg / m 3 Amide, so that the pH value reaches 8, react for about 20 minutes; then enter the sedimentation tank for sedimentation and separation, the supernatant is discharged up to the standard, and the sediment is filtered by a plate and frame filter press to obtain a solid residue. Mix solid slag with a moisture content of 80% in an amount of 15% with shale 50%, coal gangue 30% and raw coal 5%, stir and mix evenly, extrude, and dry in a 160°C drying oven for 18 hours. After ...

Embodiment 3

[0036] A method of using physical and chemical methods to treat solid slag produced by electroplating wastewater to make bricks. The electroplating wastewater first enters the adjustment tank for adjustment, and then enters the reduction tank for reduction reaction. 3 Sodium metabisulfite, react for about 20 minutes to completely reduce hexavalent chromium to trivalent chromium; then enter the neutralization tank for neutralization reaction, add 2.0kg / m 3 QS electroplating wastewater treatment agent and 0.03kg / m 3 Amide, so that the pH value reaches 8, react for about 20 minutes; then enter the sedimentation tank for sedimentation and separation, the supernatant is discharged up to the standard, and the sediment is filtered by a plate and frame filter press to obtain a solid residue. The solid slag with a moisture content of 70% is mixed with 55% of shale, 30% of coal gangue and 5% of raw coal in an amount of 10% and mixed evenly, extruded and dried in a drying oven at 170°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com