Polyene phosphatidyl choline injection, and preparation method thereof

A technology of polyene phosphatidyl choline and injection is applied in the directions of pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. The problems such as decrease, instability of polyene phosphatidylcholine, etc., achieve the effects of increased stability, simple prescription and process, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

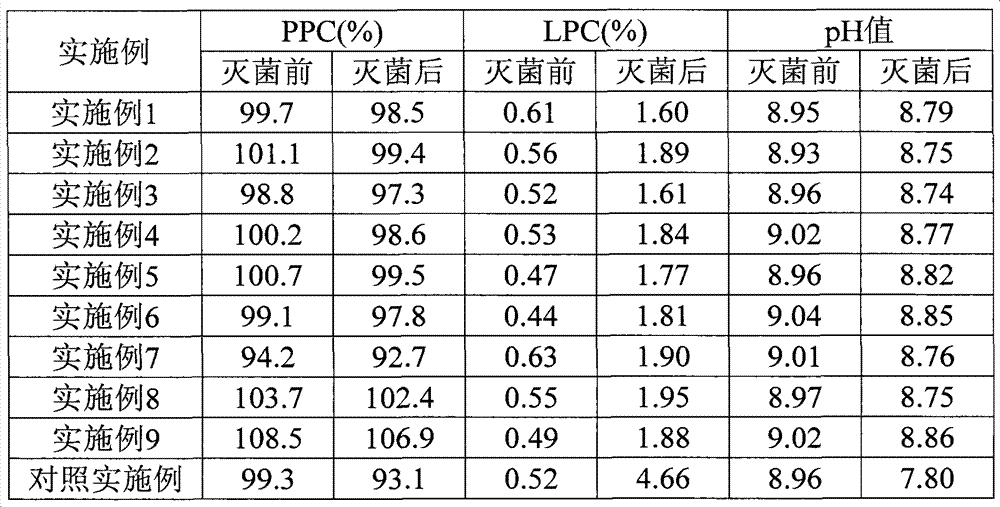

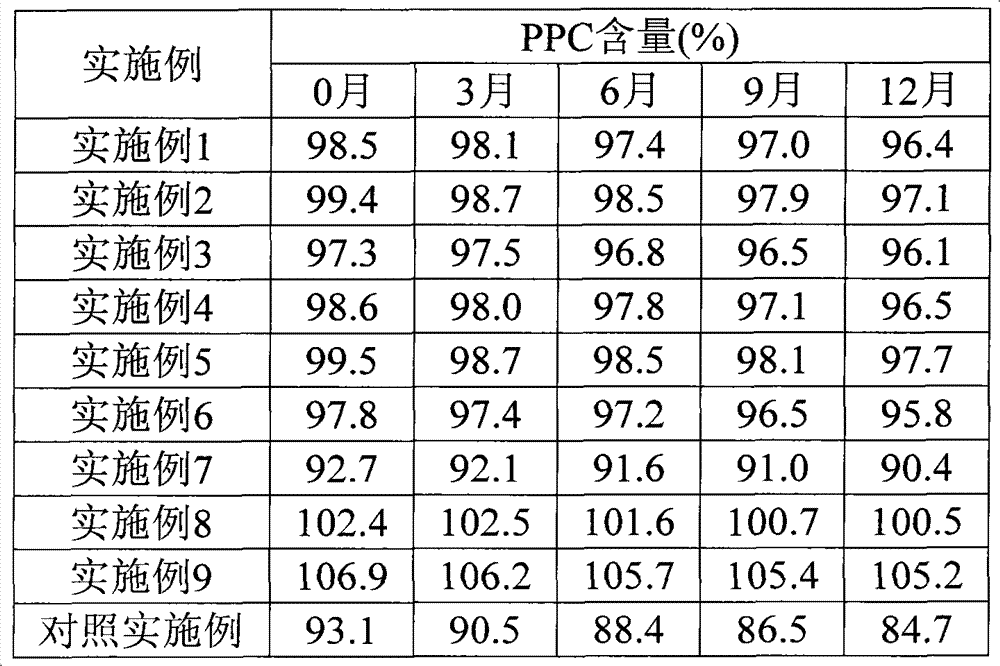

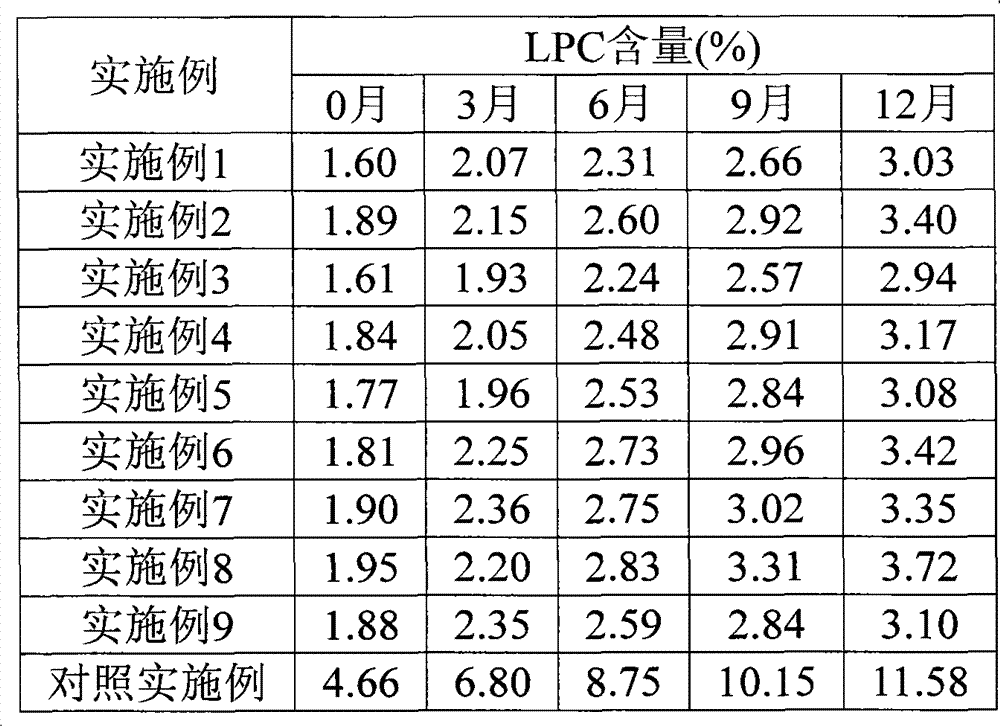

[0032] Taking the preparation of 5L polyene phosphatidylcholine injection as an example, under nitrogen protection, 232.5 g of polyene phosphatidylcholine, 150 g of deoxycholic acid, 17.8 g of arginine, Sodium chloride 16g, benzyl alcohol 48.2g, sodium hydroxide 15g and riboflavin sodium phosphate 0.45g (calculated as riboflavin), stir well; add 0.1% activated carbon for adsorption for 30min, decarbonize; use sodium hydroxide solution or dilute Adjust the pH to 9.0 with hydrochloric acid solution; add water to the prepared amount; filter, subpackage and seal under nitrogen cover, sterilize at 121°C for 12 minutes, and pass the visual inspection to obtain the product.

Embodiment 2

[0034] Taking the preparation of 5L polyene phosphatidylcholine injection as an example, under nitrogen protection, 232.5 g of polyene phosphatidylcholine, 160 g of deoxycholic acid, 19.6 g of arginine, Sodium chloride 18g, benzyl alcohol 50g, sodium hydroxide 16.3g and riboflavin sodium phosphate 0.60g (calculated as riboflavin), stir well; add 0.1% activated carbon for adsorption for 30min, decarbonize; use sodium hydroxide solution or dilute Adjust the pH to 9.0 with hydrochloric acid solution; add water to the prepared amount; filter, subpackage and seal under nitrogen cover, sterilize at 121°C for 12 minutes, and pass the visual inspection to obtain the product.

Embodiment 3

[0036] Taking the preparation of 5L polyene phosphatidylcholine injection as an example, under the protection of nitrogen, add 232.5 g of polyene phosphatidylcholine, 140 g of deoxycholic acid, and tris to 70% of the prepared water for injection. 15g, sodium chloride 10g, benzyl alcohol 47.6g, sodium hydroxide 16.8g and riboflavin sodium phosphate 0.50g (calculated as riboflavin), stir well; add 0.1% activated carbon for 30min, decarbonize; solution or dilute hydrochloric acid solution to adjust the pH to 9.0; add water to the prepared volume; filter, subpackage and seal under nitrogen cover, sterilize at 121°C for 12 minutes, and pass the visual inspection to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com