Antibacterial drug injection containing poloxamer 407 and oily medium

An antibacterial drug, oily medium technology, applied in antibacterial drugs, medical preparations containing active ingredients, pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. Preparation of 10% Ceftiofur Hydrochloride Injection

[0028] Preparation composition: 90% ceftiofur hydrochloride 110g, P407 60g, H-HPC 30g, and soybean oil for injection to 1 liter.

[0029] Preparation method: (1) Melt P407 at 60-70°C, add H-HPC and mix well, add methanol equivalent to 2 times the amount of ceftiofur hydrochloride, wait until H-HPC is dissolved and cool to room temperature, add ceftiofur hydrochloride , Fully mix, remove methanol under reduced pressure, cool, solidify, pulverize, and pass through a 40-mesh sieve to obtain drug-loaded particles containing ceftiofur hydrochloride. (2) Disperse the drug-carrying particles in part of soybean oil, grind it with a colloid mill to a particle size of less than 50μm, and then grind it with a sand mill until the particle size is less than 10μm, add the remaining medium, and use a high-shear homogenizer to Under the condition of about 5000 rpm, after repeated homogenization, ceftiofur hydrochloride injec...

Embodiment 2

[0030] Example 2. Preparation of 8% Ceftiofur Hydrochloride Injection

[0031] Preparation composition: 90% ceftiofur hydrochloride 90g, P407 80g, IPM added to 1 liter.

[0032] Preparation method: (1) Melt P407 at 60-70°C, add ceftiofur hydrochloride superfine powder, mix well, cool, pulverize after solidification, and pass through a 40-mesh sieve to obtain drug-loaded particles containing ceftiofur hydrochloride. (2) Disperse the drug-loaded particles in a part of the IPM, grind it with a colloid mill to a particle size of less than 100μm, then grind it with a sand mill until the particle size is less than 20μm, add the remaining medium, and use a high-shear homogenizer to After repeated homogenization under the condition of 5000 rpm, ceftiofur hydrochloride injection with a particle size of less than 20 μm was prepared.

Embodiment 3

[0033] Example 3. Blood drug concentration detection

[0034] Control preparation: 9g of ceftiofur hydrochloride superfine powder, 8g of P407, sterile water added to 100ml, ready to use.

[0035] Select 6 healthy pigs weighing about 30 kg, and randomly divide them into two groups A and B, each with 3 pigs. The control preparation and the preparation of Example 2 were injected intramuscularly at a dose of 8 mg / kg bw. The crossover test method was adopted. The test interval is 20 days, the blood is collected on time, the plasma is separated by centrifugation, the plasma samples of the same group at the same time are mixed in equal amounts, and the test samples are obtained through the processes of extraction, purification, and concentration. High pressure liquid chromatography (C 18 Column) Determine the concentration of ceftiofur in plasma. The experimental results are shown in Table 1 and Table 2.

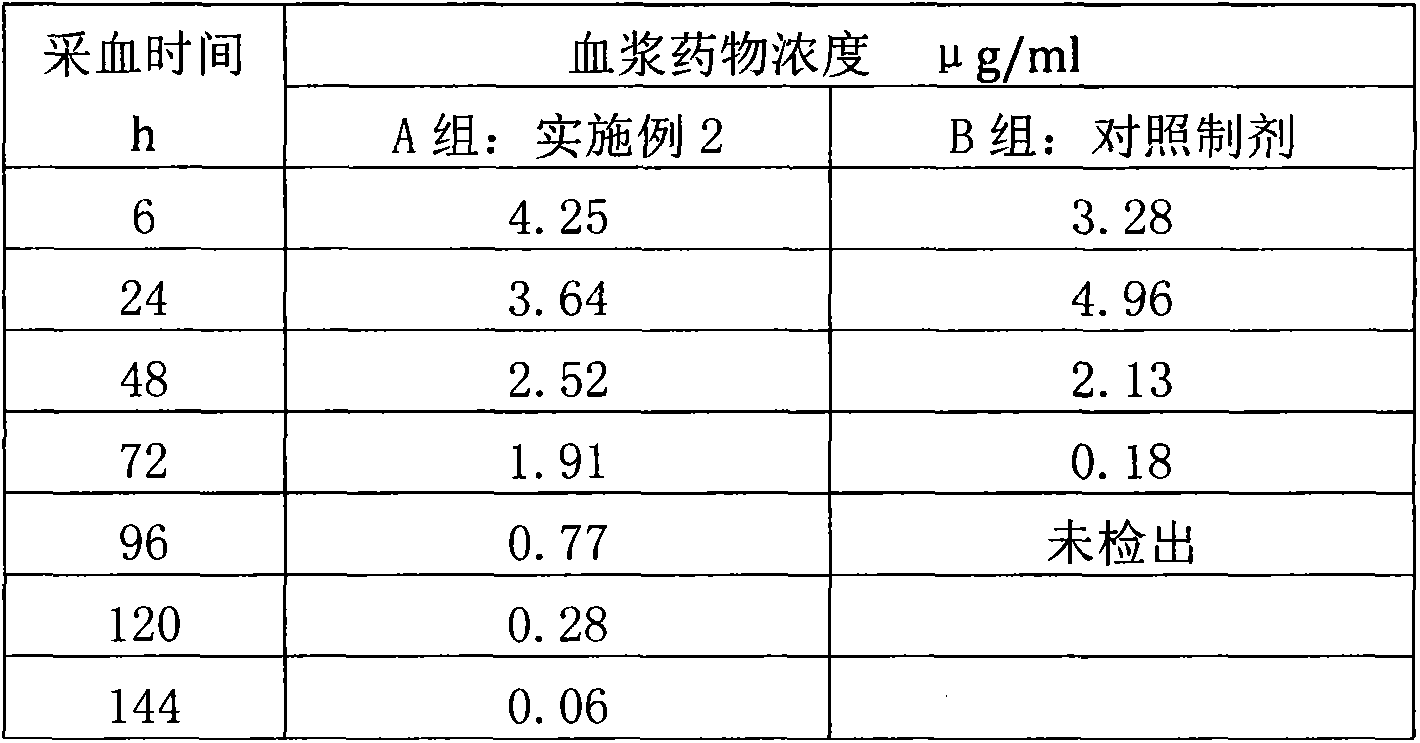

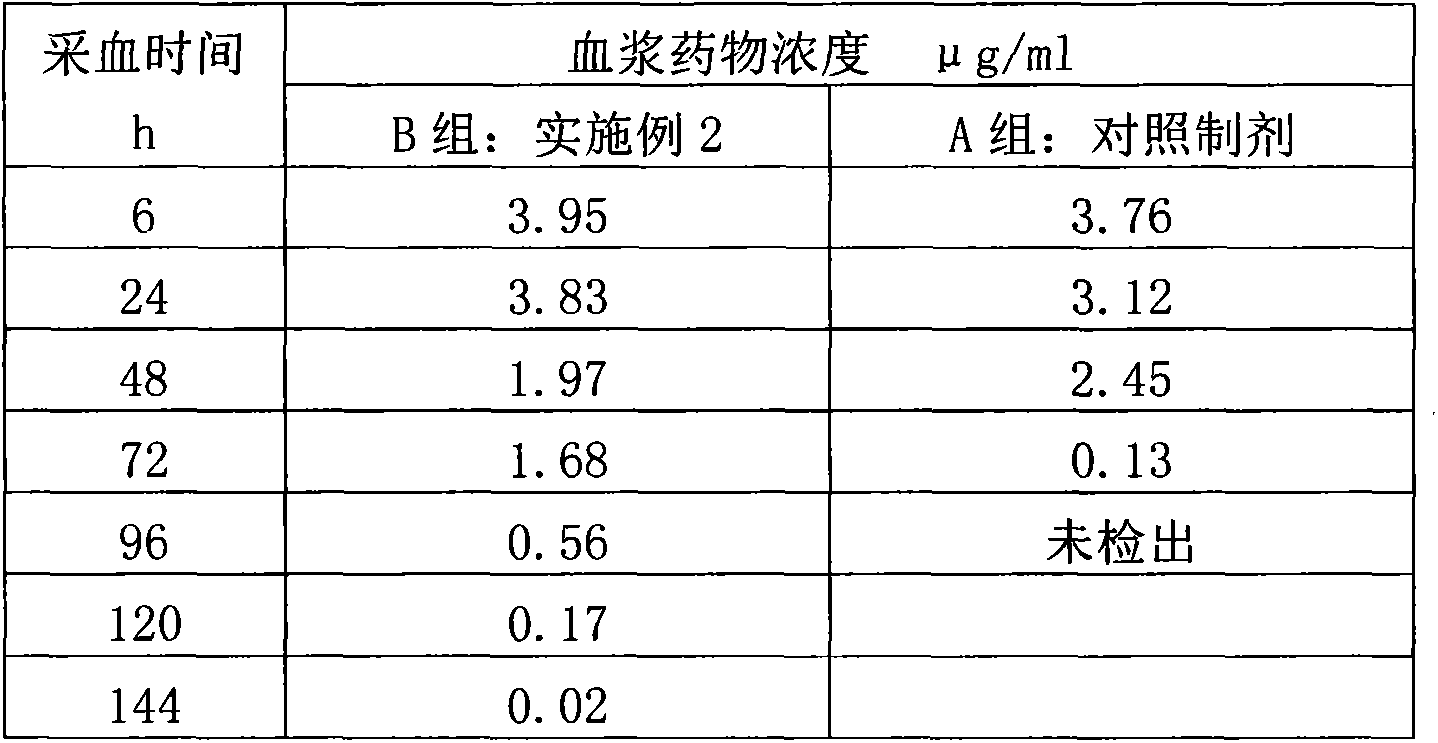

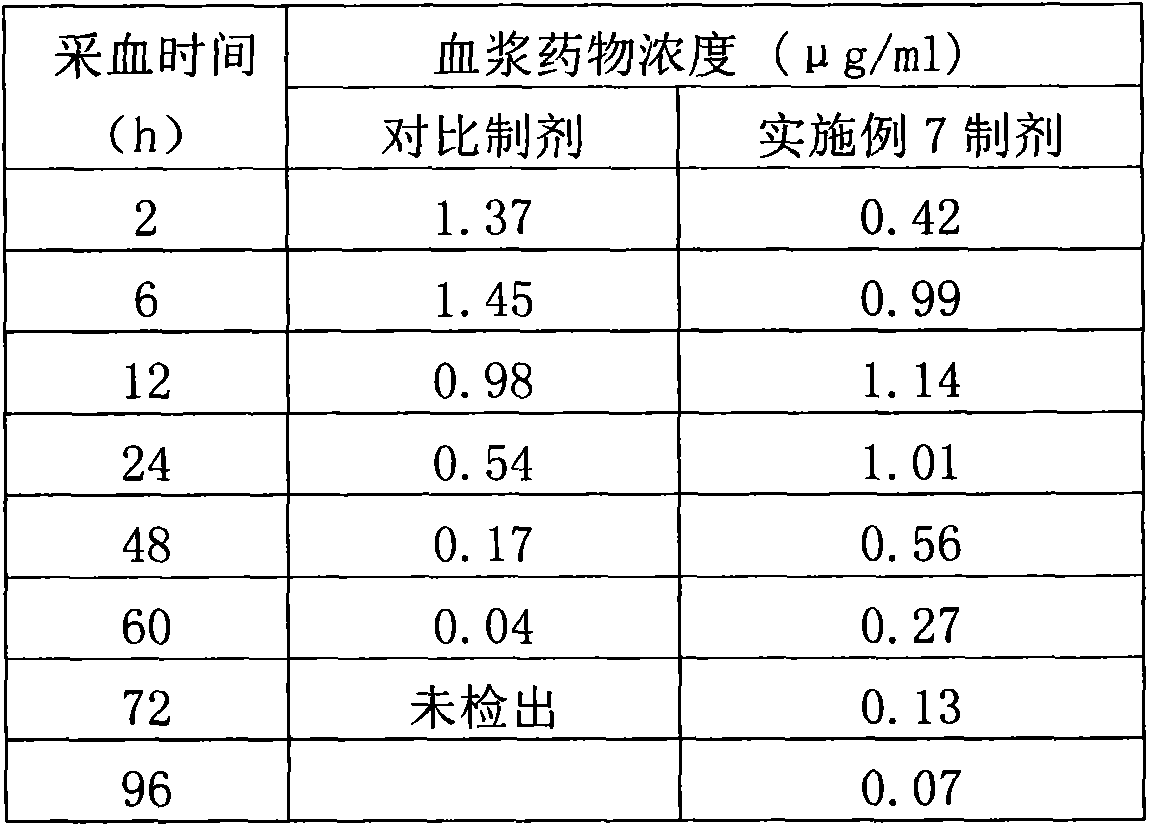

[0036] Table 1. Results of the first test

[0037]

[0038] ※The value in the table i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com