A kind of preparation method of cerium oxide/copper oxide composite nano-film catalyst

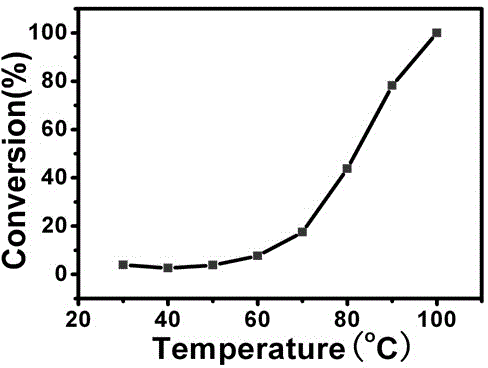

A technology of copper oxide and nano-membrane, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to improve the catalytic activity of materials, and achieve lower catalytic temperature, high catalytic performance, and improved The effect of load ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Add copper nitrate with a total substance amount of 10mmol, cerium nitrate at a ratio of 1:1 and 3-5g of materials that can increase the viscosity of the solution into 20-50ml of aqueous solution, at 60-80 o C for 15-24h, and then spread the resulting solution on the pre-treated template. Then, place the template coated with the solution at 400-600 o C under insulation 4-6h, promptly makes described cerium oxide (CeO 2 ) / copper oxide (CuO) composite nanofilm catalyst.

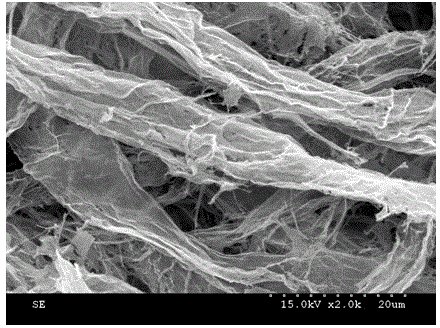

[0019] The templates used are made of filter paper or cotton wool fibers.

[0020] Stencils were sonicated with ethanol to remove dust and impurities adsorbed on the surface of the stencil material before use.

[0021] In the scheme, the material capable of increasing the viscosity of the solution is one of citric acid, polyvinylpyrrolidone, and polyethylene glycol.

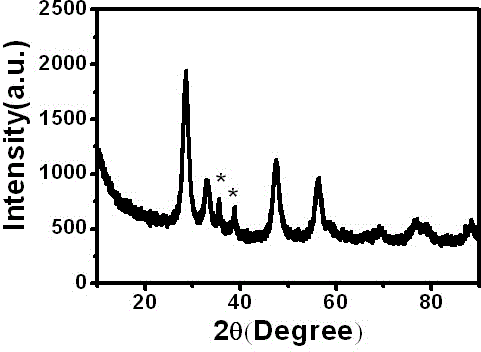

[0022] The phase structure of the obtained product was determined by XRD, the morphology of the obtained product was observed by SEM, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com