Treatment method and device for concentrating, drying and detoxifying spent catalyst carried by isobutene in isobutane dehydrogenation to isobutene

A technology for producing isobutylene from waste catalysts, which is applied in the direction of catalysts, metal/metal oxide/metal hydroxide catalysts, carbon compound catalysts, etc., and can solve the problems of large floor area, easy foaming of solvents in the washing tower, and the activity of waste catalysts. low level problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

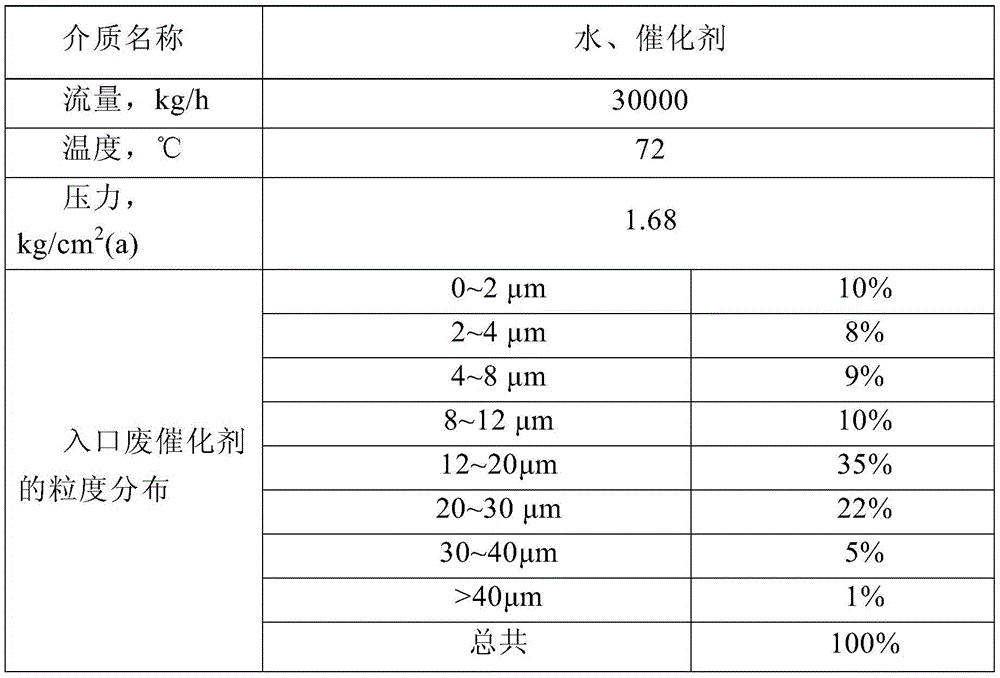

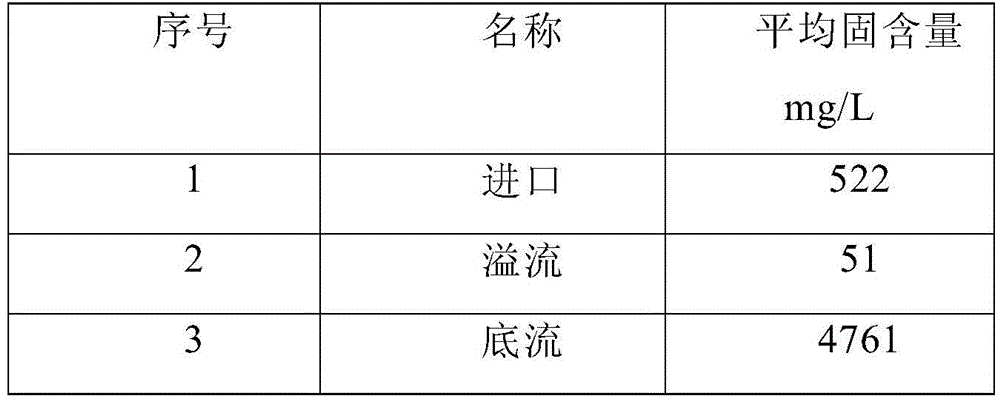

[0073] In a 100,000-ton / year isobutane dehydrogenation isobutene plant, according to the method of the present invention, the combination of a micro-cyclone separator and a filter press is used to separate and treat the washing wastewater. The specific operation process and effects are described as follows:

[0074] 1. The physical parameters of the washing water in the catalyst precipitation tank of the isobutane dehydrogenation to isobutene plant. The system uses particles loaded with chromium trioxide as the catalyst, and the main active component is Cr 2 o 3 .

[0075]

[0076] 2. Process flow:

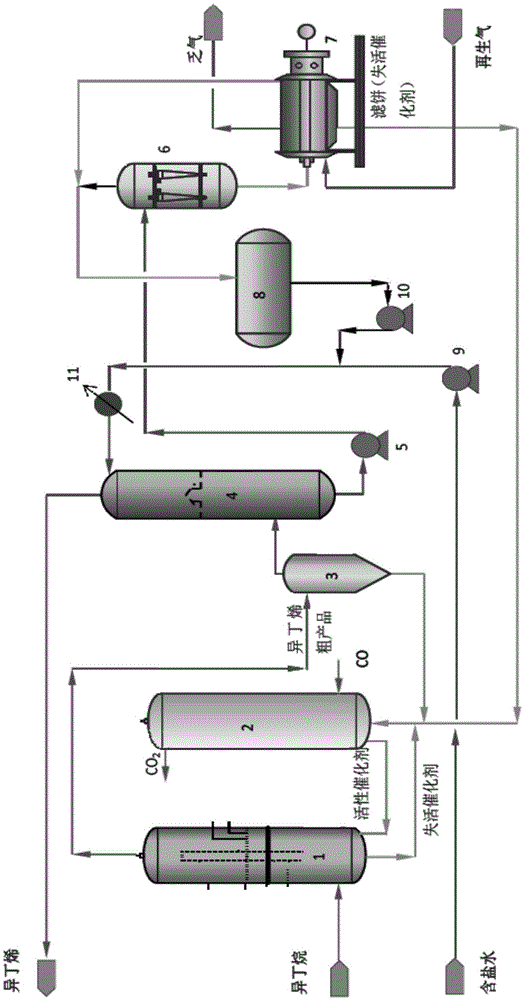

[0077] Such as figure 1 shown.

[0078]Use circulating cooling water to wash the high-temperature isobutene gas generated by the cracking reaction of isobutane to obtain washing wastewater containing spent catalyst; for the obtained washing wastewater, use the micro-swirl flow separation method to concentrate the spent catalyst particles to obtain concentrated spent catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com