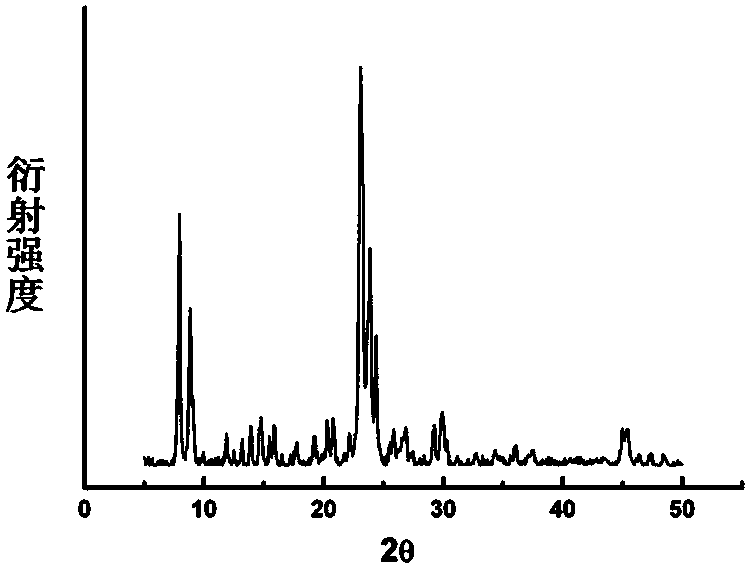

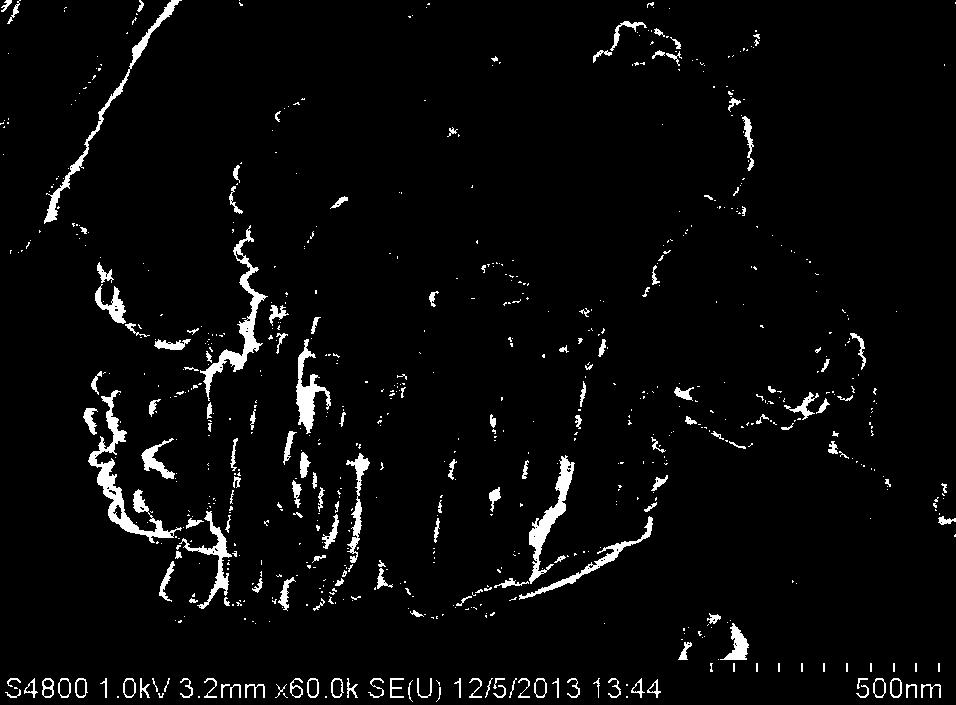

Preparation method of nanorod particle ordered-assembly ZSM-5 zeolite molecular sieve

A technology of ZSM-5 and zeolite molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of environmental pollution and cost increase, and achieve no environmental pollution and low cost , the effect suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare the initial gel in the following molar ratios: 1SiO 2 : 0.02Al 2 o 3 : 0.15Na 2 O : 0.40NaF : 65H 2 O, silica sol, aluminum sulfate, and sodium hydroxide were dissolved in deionized water respectively, and sodium chloride and 5 wt% of 200nm-sized MFI zeolite seed crystals were added under constant stirring. The above mixture was stirred and aged at room temperature for 2 hours, then put into a stainless steel static crystallization kettle with a polytetrafluoroethylene liner, and reacted at 120° C. for 48 hours. After crystallization, cool, filter and wash with deionized water for 3-4 times, and then dry the obtained sample at 80-120°C. The product is calcined in a muffle furnace or a tube furnace to remove the template agent, generally in an air atmosphere at 550 ° C for 4 to 6 hours.

Embodiment 2-5

[0025] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that during the preparation of the reaction mixture, the NaF / Si 2 O changed from 0.40 to 0.30, 0.35, 0.45, 0.50.

Embodiment 6-8

[0027] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that in the preparation process of the reaction mixture, the size of the seed crystals used is changed to 100nm, 400nm, and 600nm seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com