Preparation method of pellet binder with high performance

A technology of binder and pellets, which is applied in the field of preparation of pellet binders, can solve the problems of poor metallurgical properties of pellets, affecting iron ore into the furnace, and high burnout rate of binders. The preparation method is simple and convenient, the metallurgical performance is improved, and the effect of reducing harmful impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

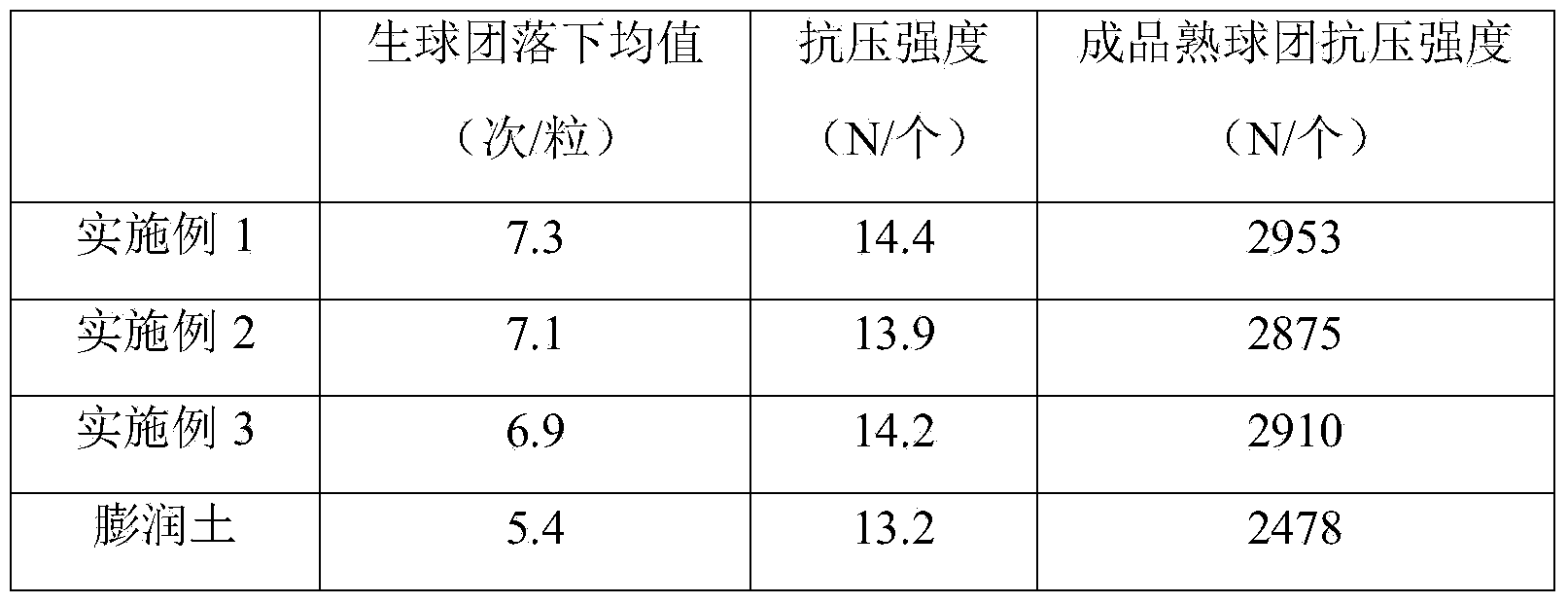

Embodiment 1

[0027] A high-performance pellet binder of this embodiment has the following components and contents: 38 kg of bentonite, 7 kg of active lime, 3 kg of polyethylene glycol, 3 kg of polyester resin, 1 kg of fly ash, and sintered ore under sieve Material 8kg, zirconia 1kg, starch 5kg, salt 2kg, polyurethane 2kg, phenolic resin 3kg.

[0028] It is worth noting that the above-mentioned active lime is also called soft burnt lime, which is lime with small crystal grains, high porosity and low bulk density obtained at a calcination temperature of about 1100°C, and the active lime used in this example has a The activity is above 330ml / 4N-HCl.

[0029] The polyethylene glycol used in the high-performance pellet binder in this embodiment is PEG-3000, the molecular weight is between 2700 and 3300, the melting point is 51-53° C., and it is milky white solid powder at room temperature. The above-mentioned polyester resins can be divided into unsaturated polyesters and saturated polyesters ...

Embodiment 2

[0039] A kind of high-performance pellet binder of the present embodiment, its basic content is the same as embodiment 1, the difference is: each component and content are as follows: bentonite 35kg, active lime 5kg, polyethylene glycol 2kg, polyethylene glycol 2kg of ester resin, 1kg of fly ash, 5kg of sinter sieve material, 1kg of zirconia, 4kg of starch, 1kg of salt, 1kg of polyurethane, and 2kg of phenolic resin.

[0040] The preparation method of a kind of high-performance pelletizing binder of the present embodiment, its steps are as follows:

[0041](1) Weigh 35kg of bentonite, 5kg of activated lime, 2kg of polyethylene glycol and 2kg of polyester resin according to the mass ratio, mix and stir in a mixer for 25 minutes at a stirring speed of 250r / min, and mix uniformly to obtain mixture A;

[0042] (2) Weigh 1 kg of fly ash, 5 kg of sinter sieve and 1 kg of zirconia according to the mass ratio, and grind the fly ash and sinter sieve in a grinder to an average particle ...

Embodiment 3

[0046] A kind of high-performance pellet binder of the present embodiment, its basic content is the same as embodiment 1, the difference is: each component and content are as follows: bentonite 42kg, active lime 8kg, polyethylene glycol 4kg, polyethylene glycol 3kg of ester resin, 2kg of fly ash, 9kg of sintered sieve material, 1kg of zirconia, 7kg of starch, 3kg of salt, 3kg of polyurethane, and 4kg of phenolic resin.

[0047] The preparation method of a kind of high-performance pelletizing binder of the present embodiment, its steps are as follows:

[0048] (1) Weigh 42kg of bentonite, 8kg of activated lime, 4kg of polyethylene glycol and 3kg of polyester resin according to the mass ratio, mix and stir in a mixer for 30 minutes at a stirring speed of 250r / min, and mix uniformly to obtain mixture A;

[0049] (2) Weigh 2kg of fly ash, 9kg of sinter sieve and 1kg of zirconia according to the mass ratio, and grind the fly ash and sinter sieve in a grinder to an average particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com