Sludge comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization

A technology of hydrothermal carbonization and anaerobic digestion, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., to ensure cleanliness and environmental safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

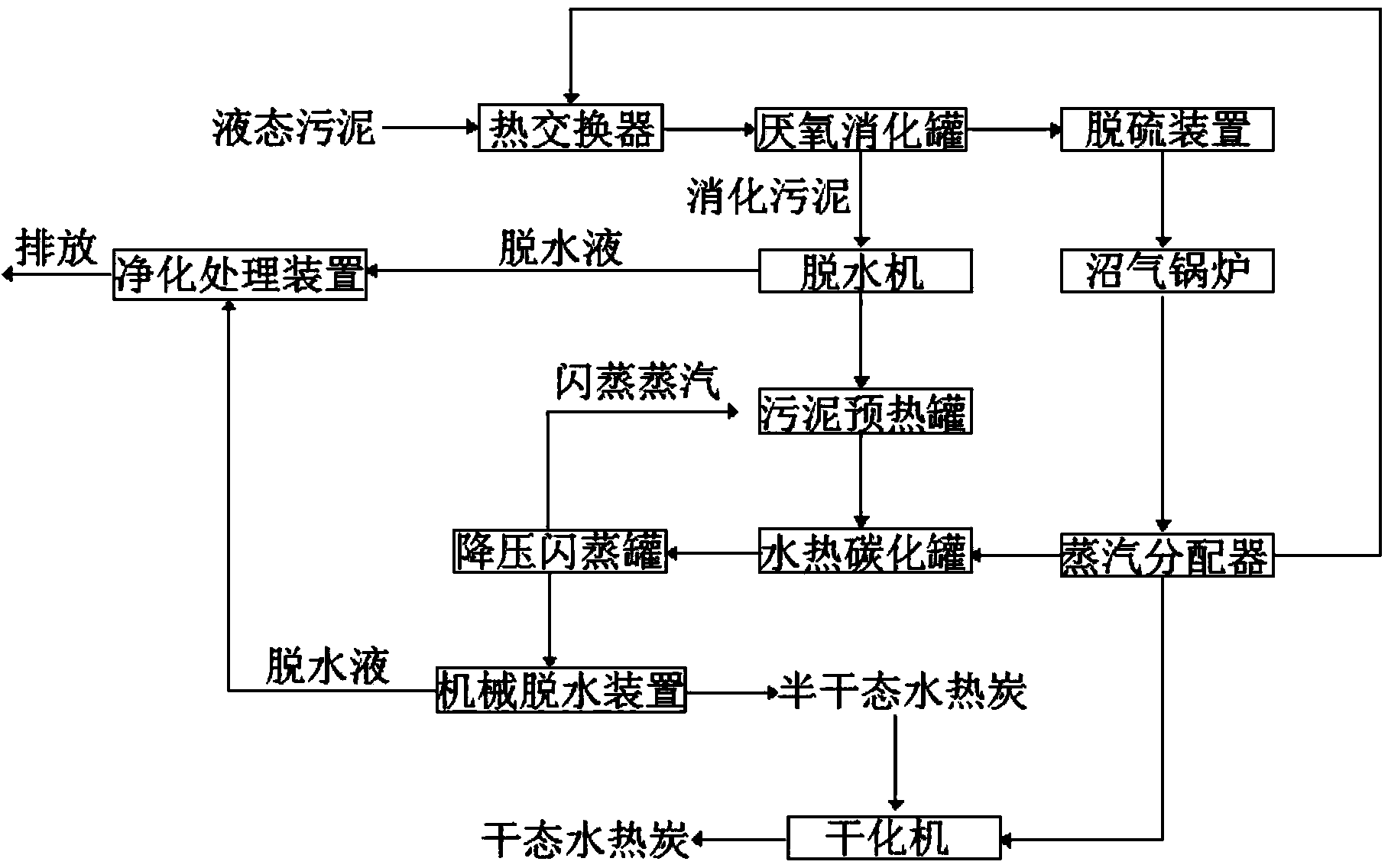

[0024] A comprehensive pollution treatment method based on anaerobic digestion and hydrothermal carbonization, including the following steps:

[0025] Step 1: Pump the liquid sludge with a moisture content of 90-98% into the heat exchanger and heat it to 50°C, and then transport it to the anaerobic digestion tank, where the liquid sludge undergoes anaerobic digestion treatment After the digested sludge is obtained, biogas is produced at the same time, and the biogas is passed to the desulfurization device, and then transported to the biogas boiler;

[0026] Step 2: Pump the digested sludge obtained through anaerobic digestion treatment in the anaerobic digestion tank in step 1 into the dehydrator for mechanical dehydration treatment, dehydrate until the moisture content of the digested sludge is 75-85%, and then transport it to the sewage The preheating treatment is carried out in the mud preheating tank, the preheating temperature is 40°C, and the preheating treatment time is...

Embodiment 2

[0032] A comprehensive pollution treatment method based on anaerobic digestion and hydrothermal carbonization, including the following steps:

[0033] Step 1: Pump the liquid sludge with a moisture content of 90-98% into the heat exchanger and heat it to 85°C, and then transport it to the anaerobic digestion tank. The liquid sludge is anaerobically digested in the anaerobic digestion tank Digested sludge is obtained and biogas is produced at the same time, and the biogas is passed to the desulfurization device, and then sent to the biogas boiler;

[0034] Step 2: Pump the digested sludge obtained through anaerobic digestion treatment in the anaerobic digestion tank in step 1 into the dehydrator for mechanical dehydration treatment, dehydrate until the moisture content of the digested sludge is 75-85%, and then transport it to the sewage The preheating treatment is carried out in the mud preheating tank, the preheating temperature is 50°C, and the preheating treatment time is 2...

Embodiment 3

[0040] A comprehensive pollution treatment method based on anaerobic digestion and hydrothermal carbonization, including the following steps:

[0041] Step 1: Pump the liquid sludge with a moisture content of 90-98% into the heat exchanger and heat it to 70°C, and then transport it to the anaerobic digestion tank, where the liquid sludge undergoes anaerobic digestion treatment After the digested sludge is obtained, biogas is produced at the same time, and the biogas is passed to the desulfurization device, and then transported to the biogas boiler;

[0042] Step 2: Pump the digested sludge obtained through anaerobic digestion treatment in the anaerobic digestion tank in step 1 into the dehydrator for mechanical dehydration treatment, dehydrate until the moisture content of the digested sludge is 75-85%, and then transport it to the sewage The preheating treatment is carried out in the mud preheating tank, the preheating temperature is 60°C, and the preheating treatment time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com