Aqueous polyurethane, and preparation method and application thereof

A water-based polyurethane, reaction technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve problems such as use restrictions, "bridging" effect, etc., to achieve low surface tension, flocculation prevention, good wetting effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Add 30g of diphenylmethane diisocyanate, 96g of methoxypolyoxyethylene ether (number-average molecular weight: 800) that has been vacuumed to remove water, 40g of 4A Acetone and 0.38 g of dibutyltin dilaurate were reacted at 45-50° C. for 0.5 h to obtain a polyurethane prepolymer. Among them, the water contents of methoxypolyoxyethylene ether (number average molecular weight: 800), acetone and dibutyltin dilaurate are 0.042%, 0.036% and 0.015%, respectively.

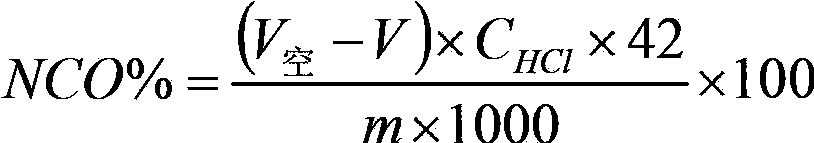

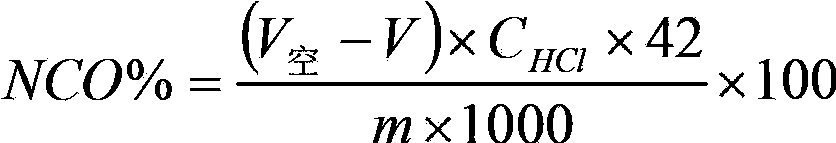

[0061] Add 5.36g of trimethylolpropane that was dewatered by vacuuming and 31g of acetone that was dewatered by 4A molecular sieves for one week to adjust the solid content in the system to 50% in the above polyurethane prepolymer. React under the condition of 50~60°C, and stop the reaction when NCO% = 0 to obtain the polyurethane containing solvent acetone. Among them, the water content of trimethylolpropane is 0.031%.

[0062] The acetone is distilled off the above-mentioned solvent-containing polyurethane und...

Embodiment 2

[0064] Add 27g of isophorone diisocyanate, 96g of allyl polyoxyethylene ether (number-average molecular weight: 800) that has been vacuumed to remove water, and 20g of 4A Ethyl acetate and 0.35 g of stannous octoate were dried with molecular sieves to remove water for one week, and reacted at 90-95°C for 2 hours to obtain a polyurethane prepolymer. Among them, the water contents of allyl polyoxyethylene ether (number-average molecular weight: 800), ethyl acetate and stannous octoate were 0.044%, 0.023% and 0.017%, respectively.

[0065] Add 5.94g of butanediol vacuumized to remove water and 12g of ethyl acetate dried with 4A molecular sieve to remove water for one week to the above polyurethane prepolymer to stabilize the solid content in the system to 80%. React under the condition of 55~65°C, stop the reaction when NCO%=0, and obtain the polyurethane containing solvent ethyl acetate. Among them, the water content of butanediol is 0.030%.

[0066] The above solvent-containi...

Embodiment 3

[0068] Add 35g of polymethylene polyphenylisocyanate and 144g of methallyl polyoxyethylene ether (number average molecular weight: 1200) to a four-necked flask equipped with tetrafluoro stirring, thermometer and condenser. 1. 80g of ethyl acetate and 0.35g of dibutyltin dilaurate were reacted at 50-55°C for 1.5h to obtain a polyurethane prepolymer. Among them, the water contents of methallyl polyoxyethylene ether (number average molecular weight: 1200), ethyl acetate and dibutyltin dilaurate are 0.041%, 0.023% and 0.015%, respectively.

[0069] Add 4.94g of propylene glycol dewatered by vacuuming and 43g of ethyl acetate dried over 4A molecular sieves for one week to the above polyester prepolymer to stabilize the solid content in the system to 60%. React under the condition of 50~55°C, and stop the reaction when NCO%=0, and obtain the polyurethane containing solvent ethyl acetate. Among them, the water content of propylene glycol is 0.027%.

[0070] The above solvent-contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com