BMC (Bulk Moulding Compound) material with weather resistance and preparation method of BMC material

A weather-resistant and weather-resistant technology, which is applied in the field of weather-resistant BMC materials and its preparation, can solve problems such as poor UV stability and hydrolysis stability, and achieve excellent acid and alkali resistance, excellent weather resistance, and excellent UV resistance. The effect of photooxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

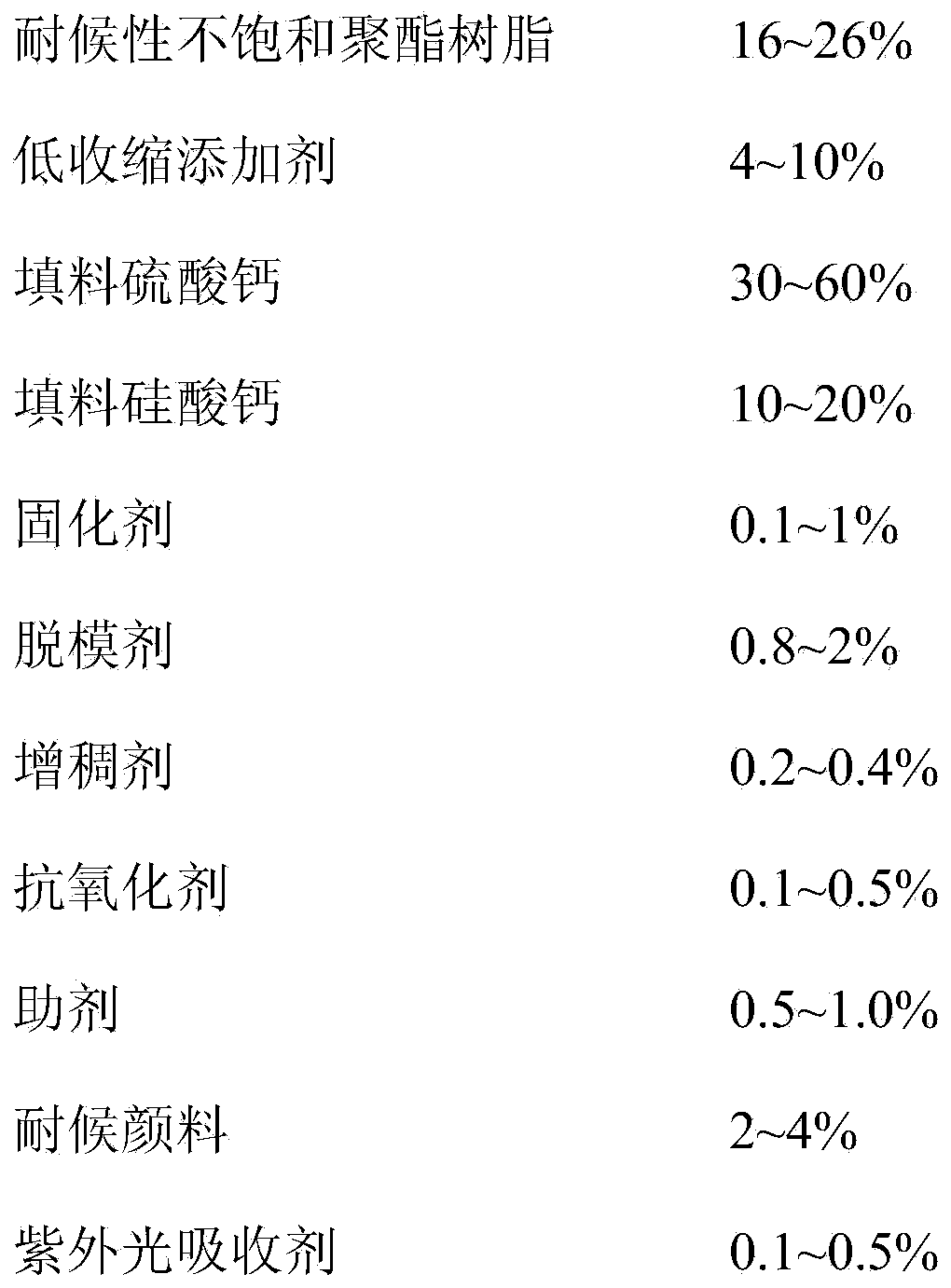

[0059] A weather-resistant BMC material, which is mainly prepared from the following raw materials according to the weight percentage of each component of the BMC material:

[0060]

[0061]

[0062] The weather-resistant unsaturated polyester resin has an HDT of 10°C and a viscosity of 1350 mPa·s; the low shrinkage additive is polystyrene with a number average molecular weight of 10,000 or more. The particle size of the filler calcium sulfate is 6-10 μm, and the particle size of the filler calcium silicate is 4-12 μm. The curing agent is tert-butyl peroxybenzoate with a purity of more than 98% and a 10-hour half-life temperature of 104°C. The release agent is calcium stearate powder, and the particle size of the calcium stearate powder is 150-250 mesh. The thickener is liquid magnesium oxide. The antioxidant is 2,6-di-tert-butyl-p-phenol. The auxiliary agent is BYK-W-996. The weather-resistant pigment is a color paste prepared by mixing and milling 10% weather-resistant colo...

Embodiment 2

[0069] A weather-resistant BMC material, which is mainly prepared from the following raw materials according to the weight percentage of each component of the BMC material:

[0070]

[0071] The weather-resistant unsaturated polyester resin has an HDT of 10°C and a viscosity of 1350 mPa·s; the low-shrinkage additive is polyethylene. The particle size of the filler calcium sulfate is 6-10 μm, and the particle size of the filler calcium silicate is 4-12 μm. The curing agent is tert-butyl peroxybenzoate with a purity of more than 98% and a 10-hour half-life temperature of 104°C. The release agent is calcium stearate powder, and the particle size of the calcium stearate powder is 150-250 mesh. The thickener is liquid magnesium oxide. The antioxidant is 2,6-di-tert-butyl-p-phenol. The auxiliary agent is BYK-W-996. The weather-resistant pigment is a color paste prepared by mixing and milling 10% weather-resistant color toner and 90% weather-resistant monomer-free unsaturated polyes...

Embodiment 3

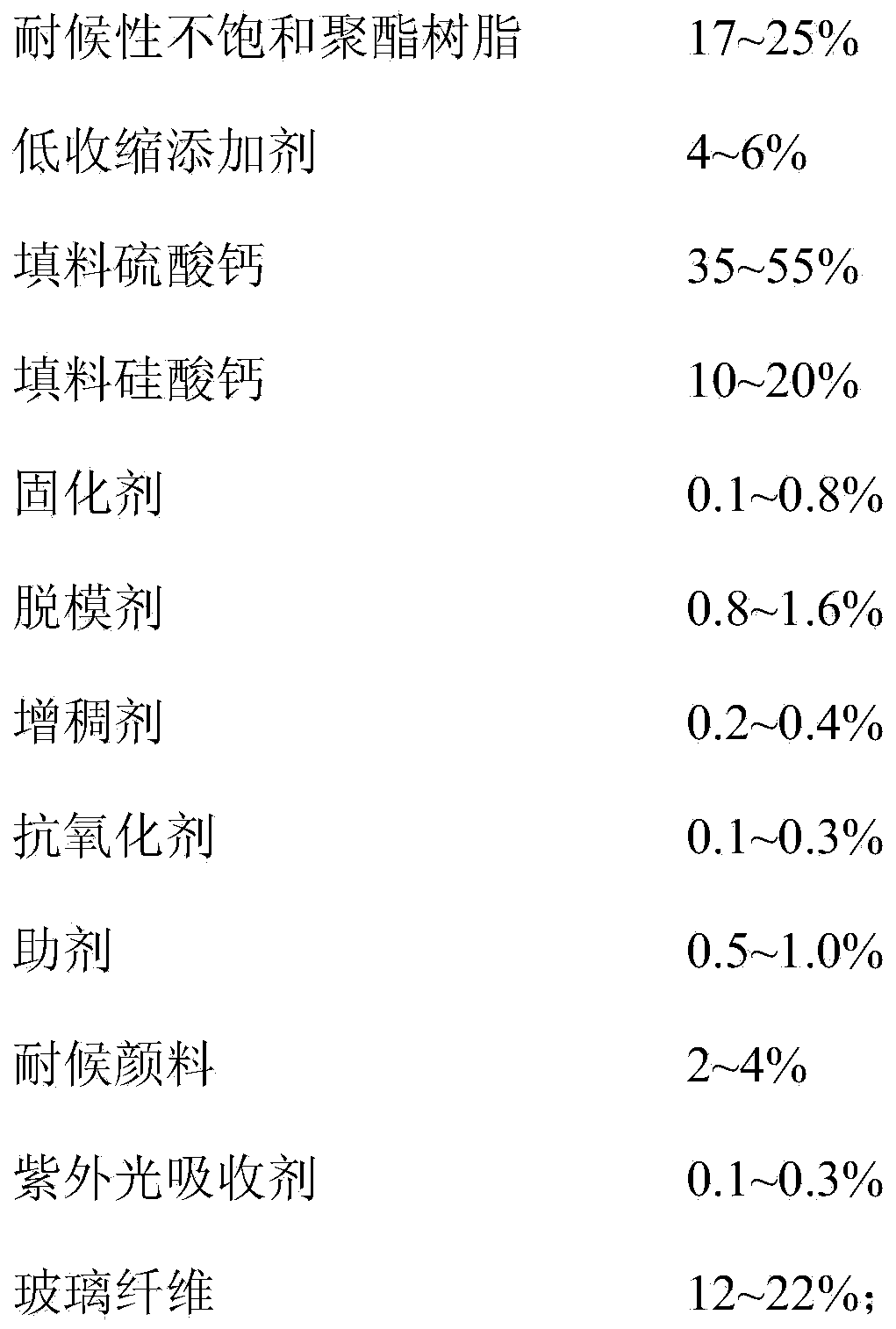

[0078] A weather-resistant BMC material, which is mainly prepared from the following raw materials according to the weight percentage of each component of the BMC material:

[0079]

[0080]

[0081] The weather-resistant unsaturated polyester resin has an HDT of 10°C and a viscosity of 1350 mPa·s; the low shrinkage additive is polystyrene with a number average molecular weight of 10,000 or more. The particle size of the filler calcium sulfate is 6-10 μm, and the particle size of the filler calcium silicate is 4-12 μm. The curing agent is tert-butyl peroxybenzoate with a purity of more than 98% and a 10-hour half-life temperature of 104°C. The release agent is calcium stearate powder, and the particle size of the calcium stearate powder is 150-250 mesh. The thickener is liquid magnesium oxide. The antioxidant is 2,6-di-tert-butyl-p-phenol. The auxiliary agent is BYK-W-996. The weather-resistant pigment is a color paste prepared by mixing and milling 10% weather-resistant colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com